2026 How to Use Oil Vacuum for Efficient Maintenance and Cleanup?

In the industrial sector, the efficient use of resources is paramount. Oil-related incidents often require immediate action. The oil vacuum system has emerged as a vital tool for maintenance and cleanup. According to a recent industry report, approximately 25% of machinery failures are related to improper oil management. This highlights the need for effective solutions.

The oil vacuum not only helps in collecting spilled oil but also aids in the filtration process. Studies indicate that routine use of oil vacuums can increase equipment lifespan by up to 30%. However, many facilities still overlook this essential maintenance tool. They continue to face unnecessary downtime and high costs.

Implementing an oil vacuum system is not without its challenges. Some workers may lack proper training. Others may underestimate its efficiency. Enhancing awareness about its benefits can significantly reduce oil-related mishaps. Investing in proper equipment is essential for long-term savings. The oil vacuum system stands as a beacon for improved operational efficiency in various industries.

How Oil Vacuum Systems Enhance Maintenance Efficiency in Industrial Settings

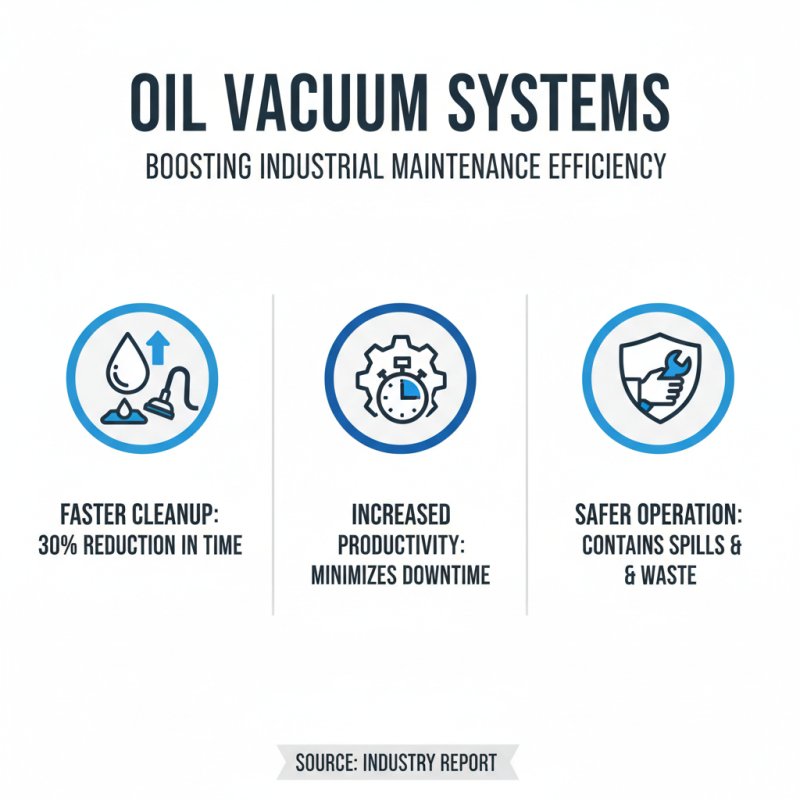

Oil vacuum systems play a crucial role in enhancing maintenance efficiency within industrial settings. These systems are designed to safely extract and contain oil spills, waste, and other contaminants. According to a recent industry report, companies that utilize oil vacuum systems reported a 30% reduction in cleanup time. This efficiency boosts productivity and minimizes downtime.

Maintenance teams appreciate the ease of using these systems. They are often lightweight and portable, allowing access to tight spaces. While these systems are effective, some users experience challenges with the suction power in larger areas. It's important for teams to regularly check their equipment's performance for optimal results.

In industrial environments, proper maintenance can prevent accidents. Studies indicate that regular oil vacuum usage can lower incidents related to oil spills by over 50%. This significant reduction emphasizes the importance of integrating these systems into routine maintenance. However, ongoing training for staff is necessary to maximize effectiveness. Skills may vary, leading to inconsistencies in how the systems are operated.

Key Features of Oil Vacuum Machines for Effective Cleanup Operations

Oil vacuum machines play a crucial role in maintenance and cleanup operations. Their primary function is to efficiently remove oil, sludge, and other liquids from various environments. Their portability allows them to be used in tight spaces where traditional methods may fail. Operators appreciate the ability to tackle heavy spills quickly and effectively.

Key features of these machines enhance their performance. Many models have powerful suction capabilities, enabling them to handle thick substances. They often come with specialized filtration systems, preventing contamination and ensuring cleaner outcomes. User-friendly controls streamline operation, but some machines can be complex for novice users. Thermal protection prevents overheating, but improper use can lead to malfunctions.

Additionally, durability is essential. High-quality materials resist corrosion, but some parts may wear out faster than expected. Regular maintenance is vital to keep oil vacuums in optimal condition. Understanding the machine's capacity is critical; overloading can cause issues. Operators sometimes underestimate the importance of regular checks and cleaning. Observing these details can greatly enhance efficiency and longevity.

2026 How to Use Oil Vacuum for Efficient Maintenance and Cleanup? - Key Features of Oil Vacuum Machines for Effective Cleanup Operations

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| High Suction Power | Powerful motors that can handle thick liquids. | Efficient oil extraction reduces downtime. | Industrial, marine, and automotive applications. |

| Portability | Compact design with wheels for easy movement. | Flexible usage in different locations. | Fieldwork and remote site maintenance. |

| Durable Construction | Robust materials designed for harsh environments. | Longer lifespan reduces overall costs. | Heavy machinery cleaning and oil spills. |

| Filtration System | Advanced filtration to separate water and oil. | Improves recovery rates and prevents contamination. | Waste management and recycling processes. |

| User-Friendly Controls | Intuitive interfaces for easy operation. | Reduces training time and user errors. | Maintenance teams and operators in various fields. |

Comparative Analysis of Oil Vacuum Types: Which is Best for Your Needs?

Choosing the right oil vacuum can significantly impact maintenance and cleanup efficiency. Different types meet varied needs. A comparative analysis reveals key distinctions among them. For instance, wet-dry vacuums are versatile. They handle both liquids and solids well. Yet, they may lack the power for heavy-duty tasks.

In contrast, portable oil vacuums excel in mobility. They allow for quick setups in tight spaces. According to industry data, portable models can improve cleanup time by up to 30%. However, their smaller capacity can be a drawback for larger jobs. If you're dealing with extensive spills, a larger industrial vacuum might be necessary. These models often feature advanced filtration systems, enhancing oil recovery rates.

User reviews indicate that versatility is crucial. Some users reveal disappointing results when expectations don't align with capabilities. Investing time in understanding your specific requirements can minimize these pitfalls. Carefully assess the features you need. Power, capacity, and mobility should all influence your choice.

Best Practices for Operating an Oil Vacuum: Maximizing Performance and Safety

Operating an oil vacuum effectively requires a thorough understanding of best practices. Proper setup is crucial. Ensure the vacuum is placed on stable ground. Check for any leaks or damages before use. Regularly inspect hoses and connections. Small cracks can lead to significant issues during operation. A good workspace can make a big difference in efficiency.

Safety should always be prioritized. Wear appropriate personal protective equipment. This includes gloves and goggles to prevent direct contact with oil. Monitor the vacuum's temperature and alerts during use. Overheating can lead to failures. Remember, an oil vacuum is a tool, not a solution. Misusing it can result in spills or accidents.

Routine maintenance of the oil vacuum is essential. Clean filters and empty tanks frequently. Neglecting these steps reduces performance. Visual inspections should be part of your routine. Look for wear and tear. Document any irregularities for future reference. A proactive approach is better than dealing with problems later. Taking time to reflect on these practices enhances your overall efficiency.

Case Studies: Successful Applications of Oil Vacuum in Various Industries

Oil vacuum systems have shown significant benefits across various industries. In the petroleum sector, a case study revealed that using a high-efficiency oil vacuum reduced cleanup time by over 30%. This was crucial during spill incidents. Additionally, a report indicated that companies employing oil vacuums saved an average of $250,000 annually in labor costs.

In the manufacturing field, factories have also embraced oil vacuums. A notable case highlighted a plant that cut waste disposal costs by 40% after adopting this technology. The efficiency increased, but there were initial challenges in employee training. Proper procedures needed refining, and user compliance was inconsistent. Addressing these issues is vital for maximizing the system's potential.

Furthermore, the automotive industry has applied oil vacuums for routine maintenance. One workshop reported that they could remove old oil twice as fast. However, irregular use of these systems raised concerns about overall maintenance. Training sessions have proven beneficial but still leave room for improvement. Ensuring staff members understand the full capabilities of oil vacuums is essential for consistent performance.

Related Posts

-

Why Air Tech is Revolutionizing the Future of Sustainable Transportation?

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Exploring Air Vacuum Innovations at the 138th China Import and Export Fair 2025

-

Understanding Regenerative Blowers: Types, Applications, and Benefits

-

Exploring the Efficiency of Oil Vacuum Pumps: The Future of Industrial Sustainability