Top Vacuum Blower Types for Effective Industrial Cleaning Solutions?

In the industrial cleaning sector, vacuum blowers play a critical role in maintaining efficiency and safety. According to a report by the Industrial Cleaning Association, proper use of vacuum blowers can reduce cleaning time by up to 30%. This statistic underscores the importance of selecting the right vacuum blower type for specific applications. Expert James Carter, a leading authority in industrial cleaning solutions, emphasizes, “The appropriate vacuum blower not only speeds up processes but also enhances air quality on-site.”

Different types of vacuum blowers cater to unique cleaning needs. Some are designed to handle heavy debris, while others operate effectively in fine dust environments. The choice depends on the operational context. For example, large manufacturing plants often require centralized vacuum systems, while smaller workshops might benefit from portable models. Despite advances, many industries still face challenges in maintaining consistent performance.

Selecting a vacuum blower requires careful consideration of various factors. Users must evaluate capacity, power, and maintenance needs. Overlooking these aspects can lead to inefficiencies and increased operational costs. As James Carter points out, understanding your specific cleaning requirements is crucial for optimizing the use of vacuum blowers in any industrial setting.

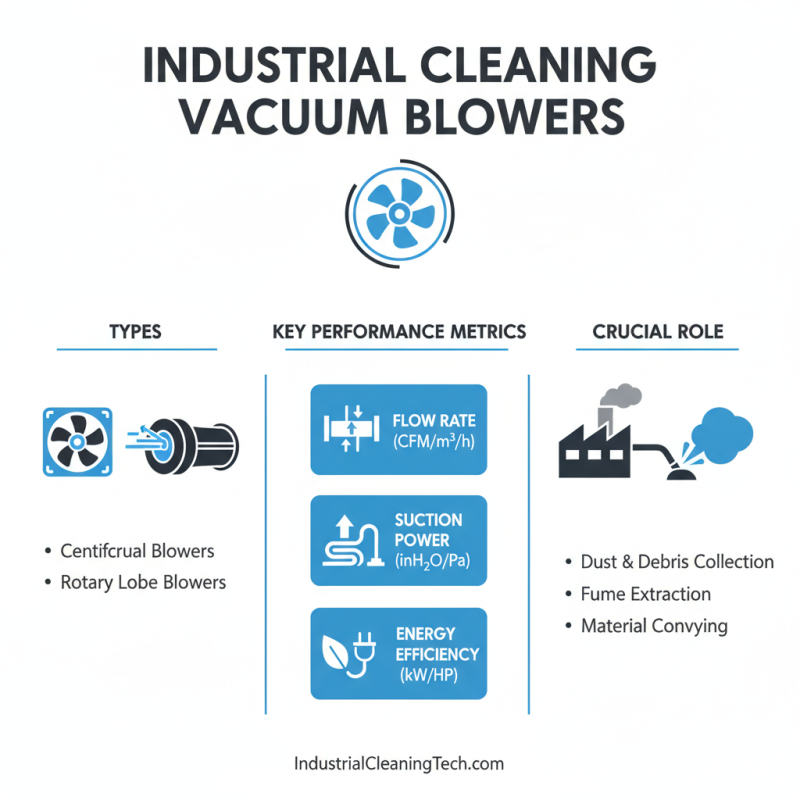

Types of Vacuum Blowers Used in Industrial Cleaning Solutions

Industrial cleaning solutions rely on several vacuum blower types. Each type serves a distinct purpose, enhancing efficiency.

Traditional positive displacement blowers, for example, are widely used because of their high suction power. These blowers excel in removing heavy debris and dust, particularly in manufacturing settings. Reports indicate that they can increase cleaning efficiency by up to 30%.

Another common type is the rotary lobe blower, favored for its ability to handle wet materials. This makes it ideal in food processing plants. Its reliability in these environments is crucial. However, maintenance can often be overlooked, leading to efficiency loss. Regular checks are essential for optimal performance. Data shows that neglecting maintenance can reduce blower efficiency by nearly 20%.

Lastly, inline centrifugal blowers are gaining traction in industrial cleaning. They provide high air volume while being energy-efficient. Their compact design allows for flexible configurations in various facilities. However, they may struggle with fine dust collection. Users should carefully assess their specific needs before choosing a type. Making an informed decision can significantly impact daily operations.

Key Features of Different Vacuum Blower Designs

When choosing vacuum blowers for industrial cleaning, design matters. Different models suit varying needs. Understanding these key features can help you make informed decisions.

Centrifugal blowers are common in many settings. They excel at generating high airflows. This feature is ideal for large areas with heavy debris. However, they might struggle with fine dust particles. Maintenance can also be challenging due to wear over time.

On the other hand, positive displacement blowers deliver consistent airflow. They effectively capture smaller particles. Their compact design makes them easy to maneuver in tight spaces. But their power consumption can be higher, leading to increased operational costs. Users might find that they require frequent inspections to maintain efficiency, which can be a hassle.

Top Vacuum Blower Types for Effective Industrial Cleaning Solutions

This chart illustrates the efficiency ratings of various vacuum blower types commonly used in industrial cleaning solutions. The ratings range from 1 to 10, indicating their effectiveness in different applications.

Comparative Analysis of Performance Metrics for Vacuum Blowers

In the realm of industrial cleaning, vacuum blowers play a crucial role. Different types of vacuum blowers are available, each offering unique advantages. When analyzing their performance metrics, key factors emerge. Flow rate, suction power, and energy efficiency are vital benchmarks.

Flow rate determines how much air a blower can move. Higher flow rates mean quicker cleaning. However, not all situations require maximum flow. Sometimes, lower rates can handle fine debris better. Suction power indicates the blower's ability to lift materials. Strong suction is essential for heavy dirt, but it can be overkill for lighter particles.

Energy efficiency matters, too. Some blowers consume more power than others. This could lead to higher operational costs. Balancing performance with energy use is necessary for many industries. There's a fine line between effective cleaning and excessive energy consumption. Finding the right blower requires careful consideration of these metrics, revealing that no single type fits all cleaning scenarios.

Choosing the Right Vacuum Blower for Specific Industrial Applications

When selecting a vacuum blower for industrial cleaning, specific applications largely dictate the choice. For example, in manufacturing plants, high-efficiency blowers are often needed. A report by the Industrial Cleaning Association indicates that nearly 70% of facilities experience dust and debris buildup that can affect machinery. Thus, the right blower is vital.

Blowers come in various types, including rotary and centrifugal. Each serves distinct purposes. Rotary blowers operate well for heavy-duty tasks, efficiently moving large amounts of air. In contrast, centrifugal models excel in applications requiring lower pressure but higher volume. These options are often recommended for environments like food processing, where strict sanitation is essential.

Nonetheless, challenges exist. Not every blower is suitable for all environments. Using the wrong type can lead to inefficiencies or even equipment damage. Regular assessments and maintenance are crucial; companies often overlook this aspect. Over time, neglecting the right blower can double operational costs, as highlighted in various industry surveys. Awareness and informed decision-making are key to ensuring optimal cleaning results.

Maintenance Tips for Optimizing Vacuum Blower Efficiency

Maintaining vacuum blowers is crucial for optimal performance. Regular inspection is essential. Check the hoses for clogs or cracks regularly. This simple step can prevent costly downtime. Keep an eye on the filters as well. Clean or replace them often to ensure airflow efficiency. Dust and debris can accumulate quickly, affecting suction power.

Lubrication plays a key role too. Ensure all moving parts are properly lubricated. This reduces wear and tear, extending the blower's lifespan. Noise is often a sign that something is wrong. Pay attention to unusual sounds during operation; they may indicate underlying issues.

Finally, user training cannot be overlooked. Operators should understand how to use the equipment effectively. Regular training sessions can help in recognizing early signs of malfunction. Not all operators are aware of best practices. This can lead to mistakes that diminish efficiency. Investing time in maintenance and training pays off in improved performance and durability.

Top Vacuum Blower Types for Effective Industrial Cleaning Solutions

| Vacuum Blower Type | Description | Best Applications | Efficiency Tips |

|---|---|---|---|

| Positive Displacement Blowers | Uses a rotating mechanism to trap and move air or gas. | Wastewater treatment, pneumatic conveying. | Regular maintenance, checking seals, and lubrication. |

| Regenerative Blowers | Offers a compact design and high efficiency through a multi-stage rotor. | Aquaculture, HVAC applications. | Optimize inlet filters and check for wear on components. |

| Side Channel Blowers | Utilizes a series of side channels to pressurize air. | Industrial vacuum cleaning, packaging. | Maintain proper airflow and monitor vibration levels. |

| Vortex Blowers | Creates vortex flow to generate suction and pressure. | Dust collection, industrial air suction. | Regularly clean the impeller and check for blockages. |

Related Posts

-

Top Factors to Consider When Choosing a High Vacuum Pump for Your Needs

-

How to Choose the Right Vacuum Industrial Solutions for Your Business Needs

-

Why Air Tech is Revolutionizing the Future of Sustainable Transportation?

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

-

Why Choosing the Right Vacuum Pump Manufacturer Matters for Your Business?