Top 10 Suction Pump Types You Need To Know For Your Applications

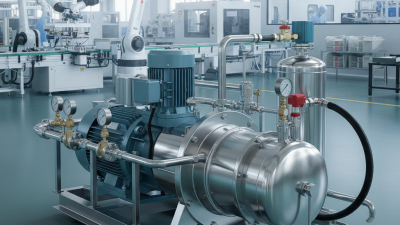

In the world of fluid management, understanding the various types of suction pumps available is crucial for maximizing efficiency and meeting specific application requirements. According to Dr. Samuel Turner, a leading expert in the suction pump industry, "Choosing the right suction pump is not just about functionality; it’s about harmonizing with the system's overall design and purpose." This insight highlights the importance of selecting the appropriate suction pump type for different operational needs, from agriculture to manufacturing and beyond.

Suction pumps play a vital role in a plethora of industries, facilitating the movement of liquids and gases through a variety of systems. Comprehending the distinct characteristics and applications of the top ten suction pump types can empower engineers and technicians to make informed decisions. Whether it's a rotary vane pump or a diaphragm pump, each type has unique features that cater to specific operational demands. Thus, this exploration of suction pump types will provide invaluable knowledge for those looking to enhance their operational efficiency and technical understanding in fluid dynamics.

Introduction to Suction Pumps: Understanding their Purpose and Applications

Suction pumps are vital components in various industries, designed to move fluids by creating a vacuum that draws substances into the pump. Their applications range from medical devices to industrial processes, showcasing their versatility and importance. Whether it's transferring liquids in a laboratory setting or providing crucial capabilities in a manufacturing line, understanding the different types of suction pumps available can significantly optimize operational efficiency.

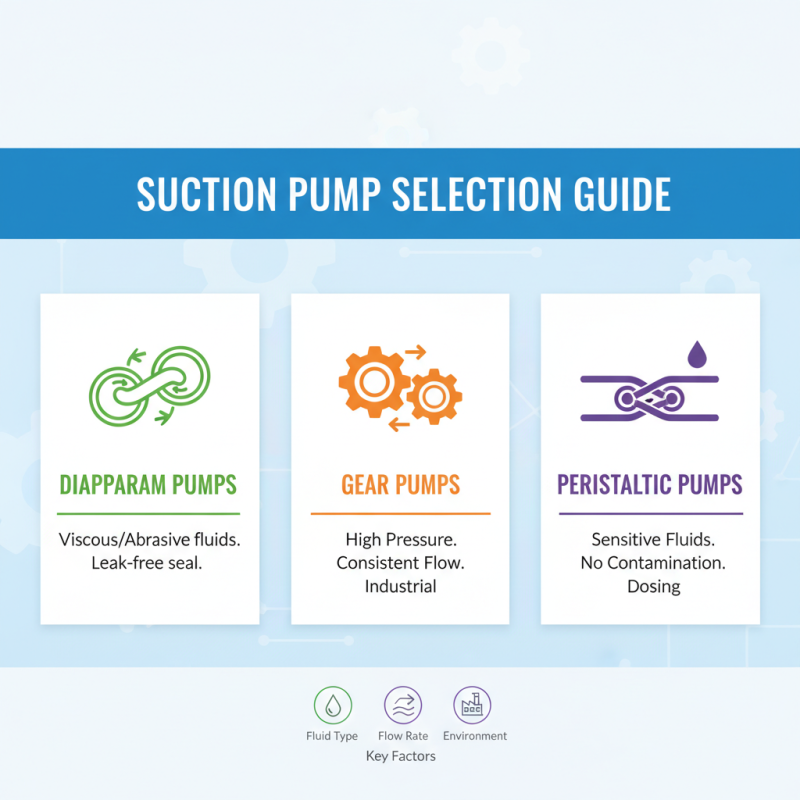

When selecting a suction pump, consider the specific needs of your application. Different pump types, such as diaphragm, gear, or peristaltic pumps, cater to distinct requirements concerning fluid viscosity, pressure, and flow rates. For specific environments, like clean rooms or hazardous locations, specialized pumps can ensure safety and compliance.

**Tips:** Always evaluate the materials used in pump construction to ensure compatibility with the fluids being handled. Additionally, pay attention to the pump's maintenance requirements; regular checks and servicing can prevent unexpected breakdowns and prolong the pump's lifespan. Understanding the operational environment can also lead to better choices in pump selection, minimizing downtime and enhancing productivity.

Top 10 Suction Pump Types You Need To Know For Your Applications

| Suction Pump Type | Application | Advantages | Disadvantages |

|---|---|---|---|

| Diaphragm Pump | Chemical transfer | Self-priming, handles viscous fluids | Limited flow rates |

| Positive Displacement Pump | Oil transfer | High efficiency with viscous liquids | Can be sensitive to pressure changes |

| Centrifugal Pump | Water supply | High flow rates, simple design | Less effective with viscous liquids |

| Vacuum Pump | Laboratory applications | Creates a vacuum, good for degassing | Limited to low pressure systems |

| Screw Pump | Oil and fuel transfer | Smooth flow, low pulsation | Higher initial costs |

| Gear Pump | Hydraulic systems | Consistent flow rate, durable | Can be noisy |

| Peristaltic Pump | Food and beverage industry | No contamination of fluid, easy to clean | Limited pressure output |

| Lobe Pump | Wastewater treatment | Good for shear-sensitive products | Higher maintenance required |

| Blower | Air conveying | Efficient for low pressure, high volume | Not effective for high pressure applications |

| Drum Pump | Transfer of bulk liquids | Portability and ease of use | Capacity limitations |

Types of Positive Displacement Suction Pumps: Features and Benefits

When it comes to positive displacement suction pumps, understanding the various types and their unique features is crucial for selecting the right pump for your application. These pumps operate by trapping a fixed amount of fluid and then forcing it through the discharge pipe, making them ideal for high-viscosity liquids and applications requiring precise flow rates. Common types include gear pumps, diaphragm pumps, and screw pumps, each offering distinct advantages for different scenarios.

Gear pumps, for example, are known for their simplicity and reliability in transferring oil and viscous liquids. They maintain a consistent flow rate and are less prone to leakage, which enhances their efficiency. On the other hand, diaphragm pumps excel in handling corrosive and abrasive fluids, thanks to their seal-less design. This feature eliminates contamination risks and extends the pump’s lifespan. Screw pumps, ideal for applications like marine or waste treatment, offer a gentle pumping action that minimizes shear, making them suitable for delicate fluids.

Tip: When selecting a positive displacement suction pump, consider the fluid properties, required flow rates, and the environment in which the pump will operate to ensure optimal performance. Regular maintenance is also essential to prolong the life of these pumps and maintain efficient operation. Another useful tip is to assess the compatibility of the pump material with the fluid to prevent corrosion and ensure durability.

Types of Centrifugal Suction Pumps: Characteristics and Uses

Centrifugal suction pumps are widely used in various applications due to their efficient performance and versatility. These pumps operate by converting rotational kinetic energy, typically from a motor, into hydrodynamic energy, which effectively moves fluids through a system. One of the primary characteristics of centrifugal pumps is their ability to handle large volumes of fluid at relatively low pressures, making them ideal for tasks such as water distribution, irrigation, and chemical processing.

There are several types of centrifugal suction pumps, each designed to cater to specific operational needs. Standard centrifugal pumps are favored for general-purpose applications, while self-priming centrifugal pumps offer the convenience of being able to draw liquid from a sump without needing additional priming equipment. Additionally, multistage centrifugal pumps are useful in scenarios requiring higher pressures, as they incorporate multiple impellers to increase fluid velocity. Each type serves unique functions, allowing users to select a pump that best fits their particular application requirements, whether it's in an industrial setting or more specialized uses.

Comparing Suction Pumps: Choosing the Right Type for Your Needs

When selecting a suction pump for your specific applications, it's imperative to consider several factors including the type of fluid being moved, required flow rate, and the operating environment. Suction pumps come in various types, including diaphragm, gear, and peristaltic pumps, each designed to cater to distinct operational needs. Diaphragm pumps are excellent for handling viscous or abrasive fluids and provide a good seal to prevent leaks. On the other hand, gear pumps are suitable for high-pressure applications, delivering consistent flow rates ideal for industrial processes.

Another crucial aspect of the selection process is understanding the suction lift capabilities of each pump. The ability of the pump to draw fluid from a source can greatly influence the efficiency of operations. Peristaltic pumps, for example, can achieve significant suction lifts, making them ideal for applications where elevation or distances must be overcome. It’s also essential to evaluate maintenance requirements and durability, as these factors can affect the long-term performance and reliability of the pump. Considering these variables will guide you in choosing the right type of suction pump that aligns perfectly with your operational demands.

Maintenance Tips for Optimal Performance of Suction Pumps

Maintaining suction pumps is essential for ensuring their optimal performance and longevity. Regular inspection and upkeep can prevent unexpected breakdowns and costly repairs. One key aspect of maintenance is lubricating moving parts. Use appropriate lubricant to reduce friction and wear, helping to maintain the efficiency of the pump. Additionally, check for any leaks or wear in seals and gaskets, as these can compromise performance and lead to system failures.

Another important tip is to routinely monitor the pump's operating conditions. Keeping an eye on the pressure and flow rates can reveal issues before they escalate. If you notice any irregularities, address them immediately. It’s also advisable to clean filters and screens frequently to avoid blockages that can disrupt the suction process. By taking these simple yet effective maintenance measures, you can ensure your suction pump operates at peak efficiency and remains reliable for your applications.

Lastly, consider implementing a scheduled maintenance program. Regularly planned maintenance checks can help identify wear and potential failures systematically. This proactive approach not only extends the life of your pump but also enhances its safety and reliability in various applications.

Related Posts

-

How to Choose the Right Suction Pump for Your Specific Needs

-

Unveiling the Secrets: How High Vacuum Pumps Revolutionize Scientific Research and Industry

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

7 Best Air Tech Innovations Transforming Your Home Experience

-

Top 10 Vacuum Pump Oils: Choosing the Best for Optimal Performance

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?