Top 10 Airtech Vacuum Pumps for Efficient Processing?

In the world of industrial processing, the choice of vacuum pumps can significantly impact performance. Airtech vacuum pumps have emerged as a leading choice for efficient processing. John Smith, a noted expert in vacuum technology, emphasizes, "Choosing the right airtech vacuum pumps can enhance productivity and reduce downtime."

These pumps not only offer superior efficiency, but they also play a crucial role in quality control. With various models, users can find pumps tailored to their specific needs. However, understanding the diverse features and specifications can be overwhelming. Often, companies neglect to evaluate their requirements thoroughly, leading to suboptimal choices.

Efficiency in processing is vital, yet choosing the right airtech vacuum pumps is a nuanced decision. Each pump has unique capabilities that may not meet all processing demands. It's essential for businesses to reflect on their long-term goals. Investing in the right technology can yield significant returns, but this must start with informed decisions.

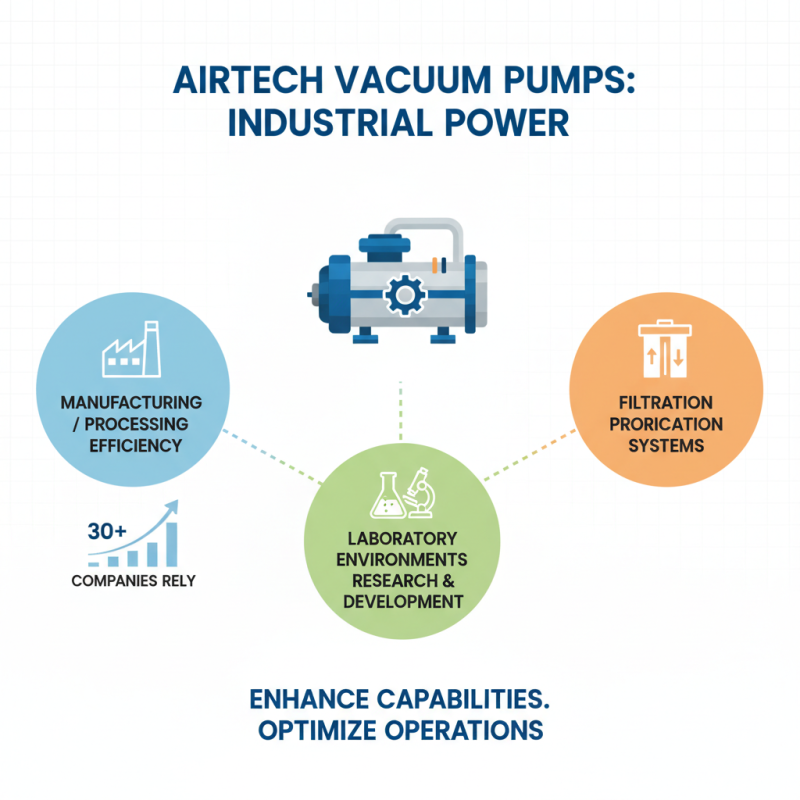

Overview of Airtech Vacuum Pumps and Their Applications

Airtech vacuum pumps play a crucial role in various industrial applications. Their efficiency can significantly enhance processing capabilities. These pumps are widely used in manufacturing, laboratory environments, and filtration processes. According to industry data, over 30% of manufacturing companies rely on vacuum technology for their operations.

In the semiconductor industry, vacuum pumps are essential for creating the perfect environment for chip fabrication. The precision required in this sector demands high reliability and performance. Similarly, in the food processing industry, these pumps ensure that products are packaged without contamination. This is vital for maintaining quality and safety standards.

Tips: Regular maintenance can extend pump lifespan. It's also critical to choose the right pump size for your application. Oversized pumps may lead to inefficiencies, while undersized pumps can cause performance issues. Evaluating your specific needs can prevent these common pitfalls. Remember, not all vacuum pumps suit every task; carefully assess the required specifications.

Key Features to Look for in Airtech Vacuum Pumps

When selecting an airtech vacuum pump, certain key features are crucial for efficient processing. First, consider the pump's flow rate. A higher flow rate allows for quicker operation. This can save time and increase productivity in various applications. Additionally, the pump's ultimate vacuum level tells you how much pressure it can remove. A lower ultimate vacuum means better performance in applications needing deep vacuum.

Durability matters too. Look for pumps made from robust materials that can withstand harsh working conditions. The noise level is another aspect to think about. A quieter pump can improve the working environment. Easy maintenance features are essential. Regular upkeep keeps the pump running efficiently. On the flip side, some pumps may require more frequent servicing than expected.

Power consumption is vital for long-term cost efficiency. A pump that uses less energy will save on electricity bills. However, be cautious of pumps that seem energy-efficient but compromise on performance. Lastly, usability features like digital displays can enhance operator experience. It’s easy to overlook these details under pressure. Finding the right balance between features often takes time and experience.

Make sure to research thoroughly and weigh your options carefully.

Comparison of the Top 10 Airtech Vacuum Pumps

When selecting airtech vacuum pumps, efficiency is key. These pumps are essential for various industrial applications. They help maintain consistent performance in processing environments. Their design impacts energy consumption and overall output quality. A thorough comparison of different models reveals significant variations.

Some pumps operate quietly, making them ideal for sensitive workspaces. Others might have a higher capacity but can be noisy. This raises questions about the trade-offs between power and noise levels. Efficiency can also fluctuate based on the material being processed. It is vital to evaluate these factors based on specific needs.

Performance metrics such as flow rate and pressure levels are critical. However, not all specifications are clear-cut. Many models may have misleading labels. A deeper analysis can often expose inconsistencies. Users should not overlook maintenance practices as they greatly affect longevity. Investing time in understanding these intricacies leads to better decisions.

Top 10 Airtech Vacuum Pumps for Efficient Processing

| Model | Max Vacuum (Torr) | Flow Rate (CFM) | Motor Power (HP) | Weight (lbs) | Noise Level (dB) | Price ($) |

|---|---|---|---|---|---|---|

| Model A | 29.9 | 8.5 | 1.0 | 60 | 70 | 1200 |

| Model B | 28.5 | 7.0 | 0.75 | 55 | 68 | 950 |

| Model C | 30.0 | 10.0 | 1.5 | 65 | 75 | 1500 |

| Model D | 27.0 | 5.5 | 0.5 | 50 | 65 | 800 |

| Model E | 31.5 | 12.0 | 2.0 | 70 | 80 | 1800 |

| Model F | 29.0 | 9.0 | 1.3 | 58 | 72 | 1400 |

| Model G | 30.5 | 11.5 | 1.8 | 67 | 78 | 1600 |

| Model H | 28.0 | 6.5 | 0.6 | 52 | 66 | 850 |

| Model I | 32.0 | 14.0 | 2.5 | 74 | 82 | 2000 |

| Model J | 26.0 | 4.0 | 0.4 | 48 | 64 | 700 |

Performance Metrics: Efficiency and Reliability Ratings

When it comes to vacuum pumps, efficiency and reliability are key. Selecting the right pump can significantly impact your processing tasks. Look for pumps with high efficiency ratings, as they save energy and time. Reliability ratings indicate how well a pump performs over extended periods. A pump that breaks down often can disrupt workflows. This should be a consideration in your choice.

Here’s a tip: always check product reviews that focus on performance metrics. These reviews often provide insights into how specific models handle real-world tasks. Don't ignore user feedback; it often highlights critical issues before you face them.

Another tip is to evaluate maintenance requirements. Some pumps may need frequent servicing, which can add to your costs. A reliable pump often requires less frequent maintenance. Seek information that breaks down these needs in user manuals and specifications. This ensures you make the right choice for your operations. Remember, efficiency is essential, but so is a pump that you can count on day after day.

Top 10 Airtech Vacuum Pumps for Efficient Processing

Maintenance Tips for Optimizing Vacuum Pump Performance

Proper maintenance of vacuum pumps is crucial for optimal performance. Regular checks can prevent costly downtime. Start by inspecting the oil levels regularly. Low oil can lead to overheating and reduced efficiency. Monitor for leaks in hoses and fittings; even small leaks can waste energy and reduce vacuum pressure.

Tips for maintenance: Keep the pump clean. Dust and debris can lead to mechanical failures. Schedule routine lubrication based on your pump’s requirements. Check filters often, as clogged ones can hinder performance. A visual inspection can reveal potential issues before they escalate.

Consider user feedback on pump performance. Understanding the common problems faced by others can offer insights. Ensure you document any irregularities. This record can help identify persistent issues. Addressing these matters promptly enhances the lifespan of your equipment.

Related Posts

-

Why Choosing the Right Vacuum Pump Manufacturer Matters for Your Business?

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

-

Top Factors to Consider When Choosing a High Vacuum Pump for Your Needs

-

2026 How to Choose the Right Vacuum Blower Pump for Your Needs?