Understanding Regenerative Blowers: Types, Applications, and Benefits

Regenerative blowers, also known as side channel blowers, play a pivotal role in various industrial applications due to their efficiency and reliability. According to a recent report by MarketsandMarkets, the regenerative blower market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, driven by increasing demand for energy-efficient systems across industries such as wastewater treatment, packaging, and pneumatic conveying. This underscores the growing significance of regenerative blowers in modern industrial processes.

Regenerative blowers, also known as side channel blowers, play a pivotal role in various industrial applications due to their efficiency and reliability. According to a recent report by MarketsandMarkets, the regenerative blower market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, driven by increasing demand for energy-efficient systems across industries such as wastewater treatment, packaging, and pneumatic conveying. This underscores the growing significance of regenerative blowers in modern industrial processes.

The technology behind regenerative blowers allows for significant energy savings, with studies indicating that they can operate at 80-90% efficiency compared to traditional blower systems. Not only does this enhance operational performance, but it also contributes to lower carbon footprints for businesses striving for sustainability. Additionally, regenerative blowers are known for their low maintenance requirements and quiet operation, making them suitable for a variety of applications from electronics manufacturing to aquaculture.

In this article, we will explore the different types of regenerative blowers available in the market, their diverse applications across industries, and the benefits they offer. By understanding the intricacies of regenerative blowers, businesses can make informed decisions that optimize their operational efficiency and drive growth in an increasingly competitive landscape.

Types of Regenerative Blowers: A Comprehensive Overview of Designs and Features

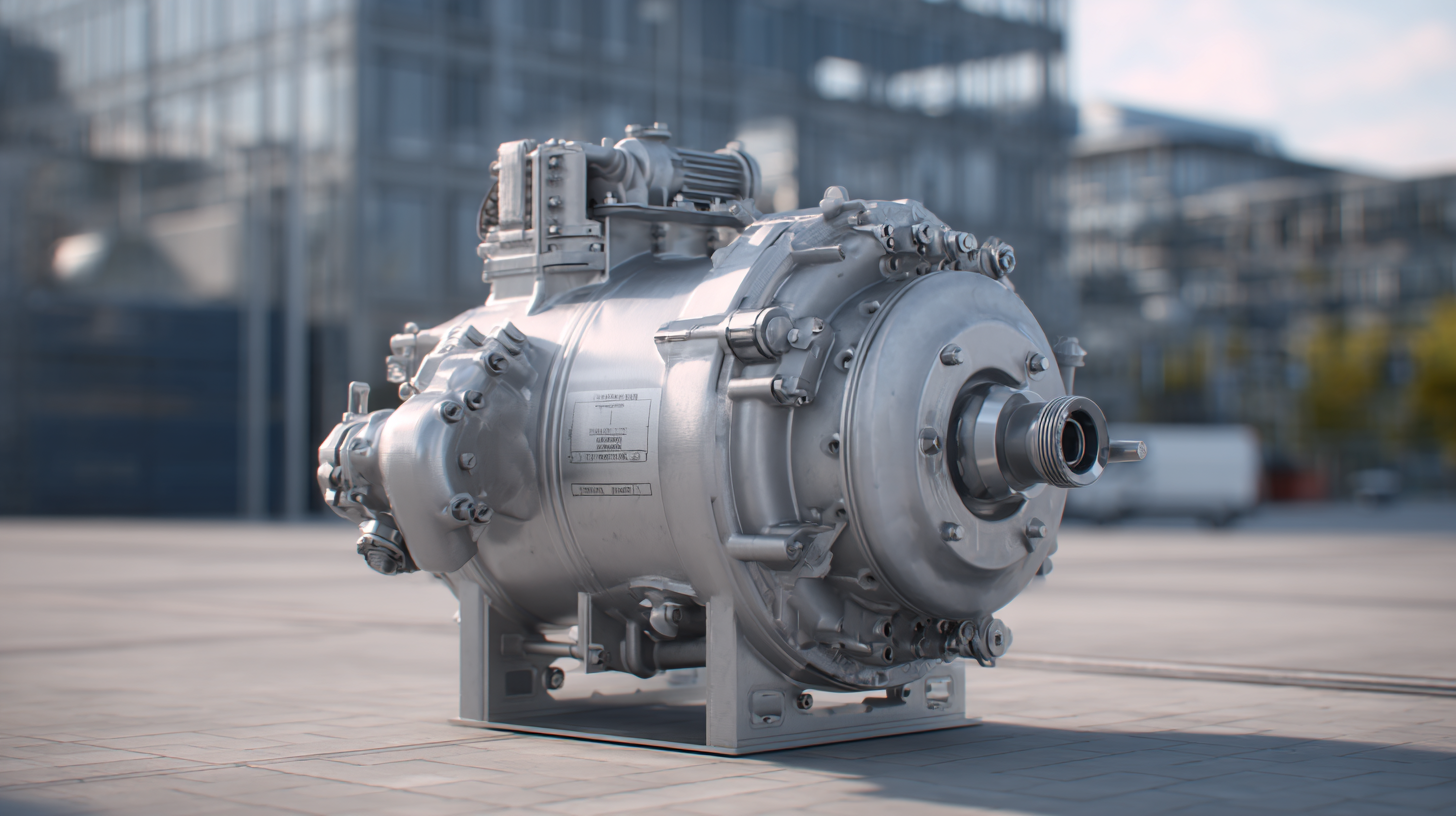

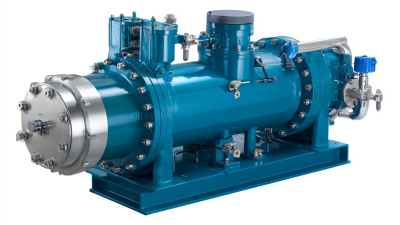

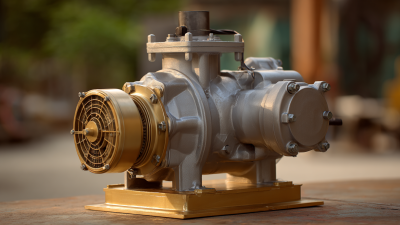

Regenerative blowers are essential equipment used in various industrial applications due to their unique design and efficient operation. These blowers primarily fall into two categories: side-channel blowers and multi-stage blowers. Side-channel blowers utilize a single rotor that spins within a casing, creating a series of pressure pulses that effectively move air or gases. This design allows for sustained high pressures and efficient airflow, making them ideal for applications such as wastewater treatment and pneumatic conveying.

On the other hand, multi-stage blowers consist of multiple rotating and stationary components that enhance air displacement by increasing pressure with each stage. This design is particularly beneficial for applications requiring high-pressure output, including enhanced aeration systems and industrial vacuum processes. Both types of regenerative blowers feature compact designs and are notable for their low noise and minimal vibration, characteristics that further broaden their usability in sensitive environments. As industries continue to seek efficient and reliable airflow solutions, understanding these design features is crucial for selecting the appropriate regenerative blower for specific applications.

Key Applications of Regenerative Blowers Across Various Industries

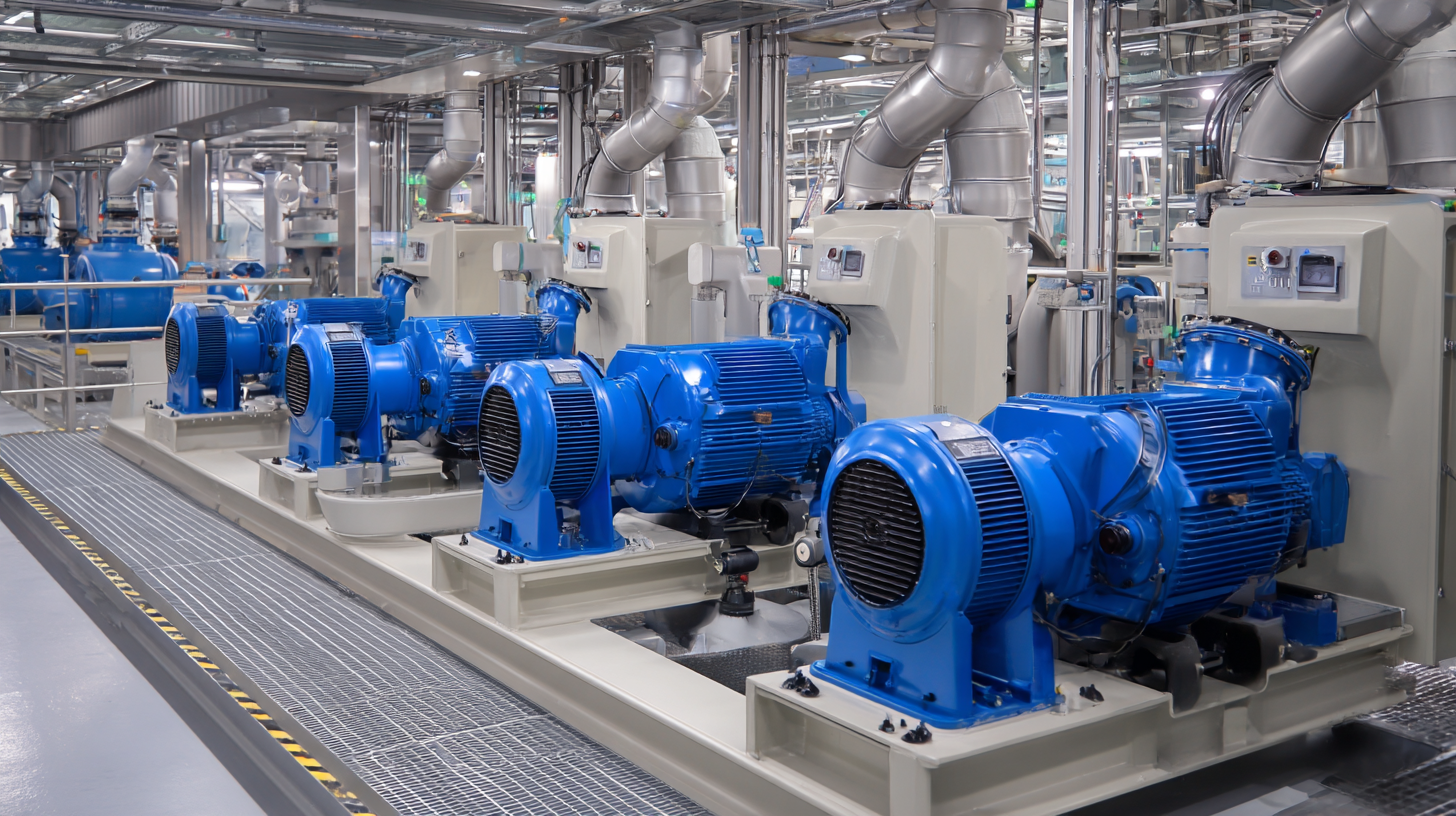

Regenerative blowers are versatile pneumatic devices widely used across various industries due to their

efficiency and reliability. One key application is in wastewater

treatment plants, where these blowers provide the necessary air required for aerobic digestion. According

to a report by MarketsandMarkets, the global wastewater treatment market is projected to reach

$720 billion by 2025, underscoring the increasing reliance on

regenerative blowers to meet growing treatment demands.

In the packaging industry, regenerative blowers facilitate the handling and movement of lightweight materials effectively. The global packaging market is expected to reach $1 trillion by 2024, and regenerative blowers contribute significantly to this growth by enabling advanced automation solutions and optimizing production lines. This illustrates the crucial impact of regenerative blower technology across multiple sectors, enhancing operational effectiveness while reducing energy consumption.

Benefits of Using Regenerative Blowers: Efficiency, Cost Savings, and Reliability

Regenerative blowers have become increasingly popular in various industries due to their numerous benefits, including efficiency, cost savings, and reliability. These blowers are designed to move air or gas utilizing a unique operating principle that gives them a distinct advantage over traditional blowers. Their ability to generate high pressure and volume with lower energy consumption results in significant operational efficiency. This is particularly advantageous for businesses looking to reduce their energy bills while maintaining effective performance.

Cost savings extend beyond just energy efficiency; regenerative blowers often have lower maintenance requirements and longer lifespans compared to other types of blowers. The simple design minimizes wear and tear, leading to decreased downtime and maintenance costs over time. Furthermore, their reliable operation ensures consistent performance in various applications, from conveying materials to wastewater treatment, which is essential for maintaining productivity in demanding environments. Emphasizing these advantages, regenerative blowers represent a smart investment for industries striving to enhance operational efficiency and sustainability.

Maintenance Tips for Optimizing the Performance of Regenerative Blowers

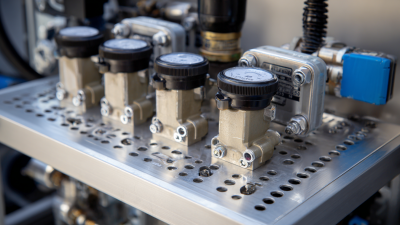

To ensure the optimal performance of regenerative blowers, regular maintenance is crucial. According to a report by the American Society of Mechanical Engineers (ASME), improperly maintained blowers can lead to a reduction in efficiency by up to 25%, directly impacting productivity in industrial applications. Routine inspections should include checking for any signs of wear on impellers and bearings, as well as ensuring that all seals are intact. It's also essential to monitor the operating temperatures, as elevated levels can indicate underlying issues that need immediate attention.

Another vital aspect of maintenance is the proper lubrication of moving parts. The International Energy Agency emphasizes that regular lubrication can enhance the longevity of regenerative blowers, potentially increasing their lifespan by 30%. Operators should adhere to manufacturer guidelines for lubrication intervals and use high-quality lubricants to prevent corrosion and friction-related damage. Additionally, keeping the airflow paths clear of obstructions is essential to avoid overheating and inefficiencies, which can further compromise the blowers' performance.

Investing time in these maintenance practices can yield significant cost savings and ensure that regenerative blowers function at their best.

Choosing the Right Regenerative Blower: Factors to Consider and Best Practices

When selecting a regenerative blower, several critical factors come into play to ensure optimal performance for specific applications. First, it's essential to consider the airflow requirements, typically measured in cubic feet per minute (CFM). According to a report by MarketsandMarkets, the regenerative blower market is projected to grow from $1.2 billion in 2021 to $1.7 billion by 2026, underscoring the increasing demand for efficient blowers across various industries. This growth is driven by the need for high efficiency and low maintenance costs, necessitating a careful evaluation of the blower’s performance specifications, including pressure range and noise levels.

In addition to technical specifications, end-users should also assess the intended application of the blower. For instance, regenerative blowers are widely used in wastewater treatment facilities, pneumatic conveying systems, and even in aquaculture for aeration. Each application may have unique requirements based on pressure, volume, and environmental conditions. Best practices include choosing a blower with adjustable flow rates and ensuring compatibility with existing systems. As the global emphasis on energy efficiency grows, selecting the right regenerative blower not only enhances operational effectiveness but also contributes to sustainability efforts in industrial processes.

Understanding Regenerative Blowers: Applications and Benefits

Related Posts

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

Top 10 Blower and Vacuum Models of 2023: Efficiency, Power, and User Ratings Reviewed

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

Revolutionizing Industries with Tailored Custom Engineering Solutions

-

How to Choose the Right Suction Pump for Your Specific Needs

-

Top 10 Blower Pumps for Efficient Air Movement and Optimal Performance