Why Are Regenerative Blowers Essential for Industrial Applications

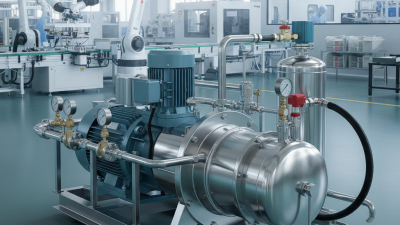

In the realm of industrial applications, regenerative blowers play a crucial role. These devices are not just tools; they are vital components ensuring efficient operations. Industries rely on regenerative blowers for various tasks, such as conveying and aerating. Their efficiency stands out when compared to traditional blowers.

Regenerative blowers offer distinct advantages. They are compact, lightweight, and capable of delivering high airflow. This makes them suitable for applications like vacuum systems and pneumatic conveying. Industries often depend on these blowers for consistent performance. However, one must ponder the maintenance needs and energy efficiency of these devices. Are they being utilized to their full potential?

The importance of regenerative blowers cannot be overstated. Their contribution to energy savings and process optimization is significant. Yet, users must continually assess their effectiveness. A proactive approach ensures that these blowers are operating at peak efficiency. In many cases, improvement opportunities exist, which can enhance overall productivity.

Understanding Regenerative Blowers: An Overview of Their Functionality

Regenerative blowers are vital in various industrial applications. Their unique functionality enables them to provide air and gas movement efficiently. According to industry reports, regenerative blowers can achieve pressures up to 15 inches of water column and flow rates exceeding 4,000 CFM. This efficiency translates to reliable performance in tasks such as pneumatic conveying, material handling, and vacuum applications.

The design of regenerative blowers is quite intriguing. They utilize a simple mechanism that repeats the intake and compression process. This can lead to some operational challenges, including noise levels that may exceed acceptable standards. In many applications, users report a need for additional soundproofing solutions. Key performance indicators highlight that while these blowers are energy-efficient, variations in manufacturing quality can cause inconsistencies in airflow and pressure output.

Moreover, the maintenance requirements can be a double-edged sword. Regular checks are necessary to ensure optimal performance. However, some facilities overlook this vital aspect, leading to inefficiencies and increased operational costs. As evidenced by maintenance logs, many operators fail to track performance data adequately, which is essential for long-term reliability. There is a clear opportunity for improvement here in many industrial settings.

Key Benefits of Regenerative Blowers in Industrial Settings

Regenerative blowers play a crucial role in various industrial applications. They efficiently move air and gases with minimal energy consumption. This efficiency can lead to significant cost savings over time. Such blowers can handle large volumes of air, making them ideal for tasks like vacuuming or aeration. They operate quietly, contributing to a better work environment.

One key benefit is their versatility. Regenerative blowers can be used in diverse settings, from wastewater treatment plants to packaging industries. Their robust design often translates to lower maintenance needs, though occasional checks are necessary. However, some users find the initial setup challenging. This complexity can deter smaller operations from adopting this technology.

Moreover, regenerative blowers help improve process efficiency and product quality. They ensure a consistent flow of air for various applications. Despite these advantages, it's important to address potential pitfalls. Users should be aware of the specific requirements of their processes. Not all systems will benefit equally from regenerative blowers. Taking the time to evaluate their needs is essential.

Why Are Regenerative Blowers Essential for Industrial Applications - Key Benefits of Regenerative Blowers in Industrial Settings

| Benefit | Description | Application Examples |

|---|---|---|

| High Efficiency | Regenerative blowers provide higher efficiency compared to traditional blowers, optimizing energy consumption. | Vacuum packaging, pneumatic conveying systems. |

| Low Noise Levels | These blowers operate quietly, which is crucial in environments where noise reduction is important. | Food processing, clean rooms. |

| Compact Size | Designed with a compact structure, these blowers can easily fit into tight spaces. | Material handling, laboratory applications. |

| Durability | Built with high-quality materials, regenerative blowers have a long lifespan and require less maintenance. | Industrial vacuum systems, water treatment facilities. |

| Versatility | Can be used for both vacuum and pressure applications across various industries. | Textile manufacturing, paper production. |

Common Applications of Regenerative Blowers in Various Industries

Regenerative blowers play a critical role in many industrial applications. These devices are widely used in wastewater treatment plants. According to a report by the Environmental Protection Agency, regeneration technology improves aeration efficiency by up to 30%. This enhances oxygen transfer and promotes healthier aquatic ecosystems.

Another significant application of regenerative blowers is in pneumatic conveying systems. They are utilized to transport bulk materials like grains and powders. Data from the Powder and Bulk Engineering Journal shows that regenerative blowers can reduce energy costs by 15% in such systems. Their low noise levels also make them suitable for environments where sound pollution is a concern.

However, it's essential to recognize the limitations of regenerative blowers. While they offer high efficiency, they may not be suitable for all applications. Some industries might experience pressure fluctuations that affect performance. Therefore, thorough analysis and testing are crucial before implementation. Balancing efficiency and application needs can be challenging but necessary for optimal results.

Maintenance and Efficiency Considerations for Regenerative Blowers

Regenerative blowers play a crucial role in various industrial applications. Their efficiency largely depends on proper maintenance. Regular checks can prevent unexpected downtimes. Maintenance tasks include cleaning filters and inspecting seals. Neglecting these tasks can lead to reduced performance and environmental issues.

Efficiency can significantly decline if blowers aren’t serviced. Clogged filters or worn components can strain the system. This affects energy consumption, increasing operational costs. Scheduling routine maintenance can help mitigate these issues. Keeping a maintenance log is also beneficial. It allows teams to track performance over time.

In some cases, businesses overlook the benefits of preventive maintenance. This can be costly in the long run. A little attention today might save bigger expenses tomorrow. Ensuring your regenerative blower is in tip-top shape can lead to better productivity. Ultimately, investing in maintenance reflects a commitment to efficiency and sustainability.

Comparative Analysis: Regenerative Blowers vs. Other Blower Types

Regenerative blowers are gaining attention for industrial applications. They offer unique advantages compared to traditional blower types. Regenerative blowers provide a continuous and efficient flow of air. This is especially important in processes requiring constant airflow, like pneumatic conveying.

In contrast, rotary blowers generate airflow through mechanical means. They can be less energy-efficient in some scenarios. Regenerative blowers, however, utilize a rotating impeller to increase air pressure. This design reduces energy loss and enhances performance. They also operate at lower noise levels, making them suitable for sensitive environments.

One drawback is their sensitivity to foreign particles. It’s crucial to maintain cleanliness in the air supply. Without proper filtration, performance can decline. Additionally, regenerative blowers may require more regular maintenance than other types. Understanding these nuances helps industries make informed decisions about their blower systems.

Why Are Regenerative Blowers Essential for Industrial Applications?

The chart above illustrates the airflow efficiency in Cubic Feet per Minute (CFM) for different types of blowers used in industrial applications. Regenerative blowers demonstrate superior efficiency compared to positive displacement, centrifugal, and screw blowers, making them a crucial choice for various industrial processes.

Related Posts

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

-

What is Air Vacuum? Understanding Its Types and Uses for Your Home

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

Why Air Tech is Revolutionizing the Future of Sustainable Transportation?

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications