What Is an Oil Less Vacuum Pump and How Does It Work?

The oil less vacuum pump is a vital piece of equipment in many industries. These pumps are known for their efficiency and environmental friendliness. According to a recent report by MarketsandMarkets, the global vacuum pump market is projected to reach $5.7 billion by 2026. This growth is largely due to the rising demand for oil less technologies.

Oil less vacuum pumps offer several advantages. They operate without oil, reducing maintenance needs and operational costs. In sectors such as pharmaceuticals and food processing, these pumps ensure contamination-free environments. Yet, they are not without challenges. Their upfront costs can be higher, and performance may vary based on specific applications.

Researchers continue to explore innovations in oil less technologies. While these pumps show promise, their limitations in extreme conditions require attention. As industries evolve, the demand for reliable vacuum solutions persists. Understanding how an oil less vacuum pump works is crucial for making informed choices in an ever-changing market.

Definition of an Oil Less Vacuum Pump and Its Purpose

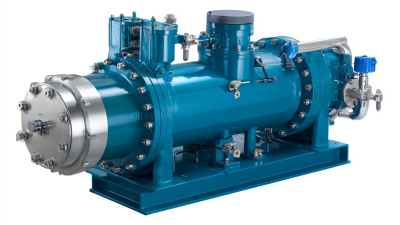

An oil-less vacuum pump is a unique piece of equipment. It operates without any oil to generate a vacuum. This design is crucial for applications where oil contamination may be a concern. Industries such as food processing, pharmaceuticals, and electronics often require a clean environment. The absence of oil minimizes risks of contamination, making this pump suitable for sensitive applications.

The purpose of an oil-less vacuum pump is to maintain a clean operation. It uses alternative technologies, such as diaphragm or piston mechanisms. These designs can be less efficient than oil-lubricated pumps, but they meet specific needs. They can handle a range of pressures and can often run quieter. However, they may not always reach the same vacuum levels as their oil-based counterparts. Users might find that while they are easier to maintain, they require careful monitoring and occasional adjustments for optimal performance.

Choosing an oil-less vacuum pump isn’t always straightforward. Users need to consider their application’s demands. While these pumps are less likely to cause contamination, they may have limitations in performance under heavy loads. Understanding these factors is essential for making an informed decision. Regular maintenance is still important, even if less oil is involved.

What Is an Oil Less Vacuum Pump and How Does It Work?

| Dimension | Details |

|---|---|

| Definition | A vacuum pump that operates without the use of oil for lubrication. |

| Purpose | To create a vacuum environment for various applications, including medical, laboratory, and industrial use. |

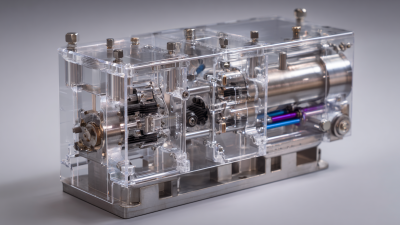

| Working Principle | Uses alternative methods such as diaphragm or rotary vane mechanisms to remove air without oil. |

| Advantages | Cleaner operation with no oil contamination, lower maintenance costs, and quieter operation. |

| Applications | Laboratory research, environmental testing, vacuum packaging, and dental practices. |

| Disadvantages | Typically less efficient and lower vacuum pressure compared to oil-lubricated pumps. |

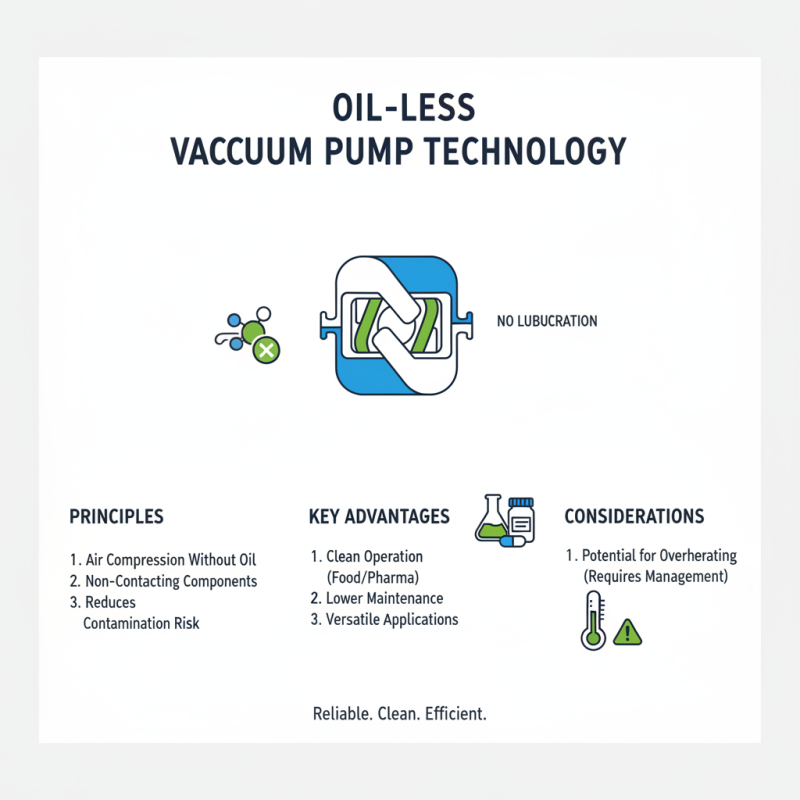

Principles of Operation for Oil Less Vacuum Pumps

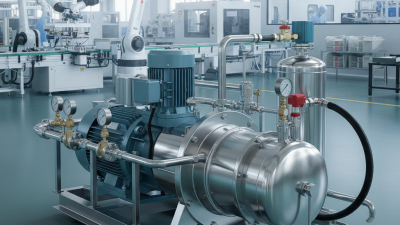

Oil-less vacuum pumps operate on specific principles that distinguish them from conventional pumps. They utilize a mechanism where the compression of air is achieved without lubrication. This design minimizes the risk of contamination, making them suitable for various applications like food processing and pharmaceuticals. The absence of oil means fewer maintenance requirements, yet this can sometimes lead to overheating issues if not managed properly.

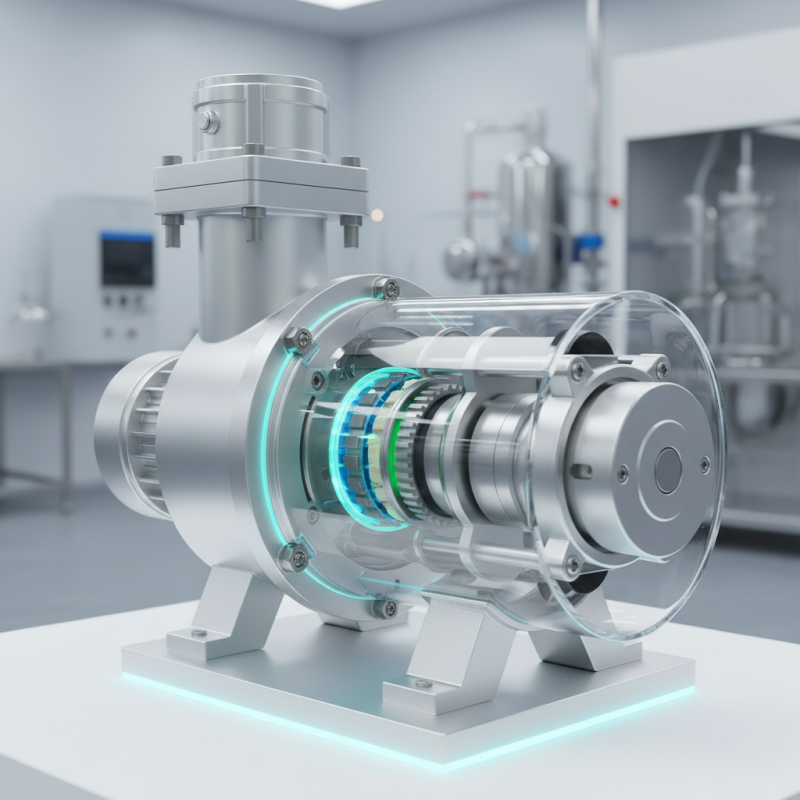

These pumps work primarily through a series of rotating vanes or pistons within a sealed chamber. As these components move, they create a pressure differential that draws air in and expels it, creating a vacuum. The efficient design allows for quick evacuation of air while maintaining energy efficiency. However, it’s crucial to ensure adequate cooling to prevent overheating. Operators need to be attentive to the pump's conditions to avoid performance drops over time.

In practice, while oil-less pumps are reliable, they may not be as powerful as their oil-lubricated counterparts. Users often question their capability in high-demand situations. Moreover, the initial investment may be higher. Regular checks and balances are needed to keep them running smoothly. Understanding these practical aspects can improve their longevity and performance.

Types of Oil Less Vacuum Pumps and Their Applications

Oil less vacuum pumps come in various types, each suited for specific applications. Diaphragm pumps are popular in laboratories. They offer a clean vacuum solution without oil contamination. These pumps work by using a flexible diaphragm to create a vacuum. They are compact and efficient, making them ideal for small spaces.

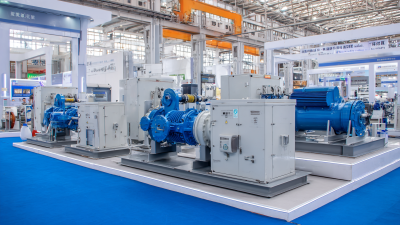

Another type is the rotary vane pump. It is widely used in industries for refrigeration and air conditioning. The rotary design ensures constant airflow. These pumps can handle a variety of gases effectively. They might not be as clean as diaphragm pumps but are versatile.

In some cases, oil less pumps may struggle with extremely low pressures. Users should consider their specific needs carefully. Finding the right balance between performance and application is crucial. Always assess what works best for your project.

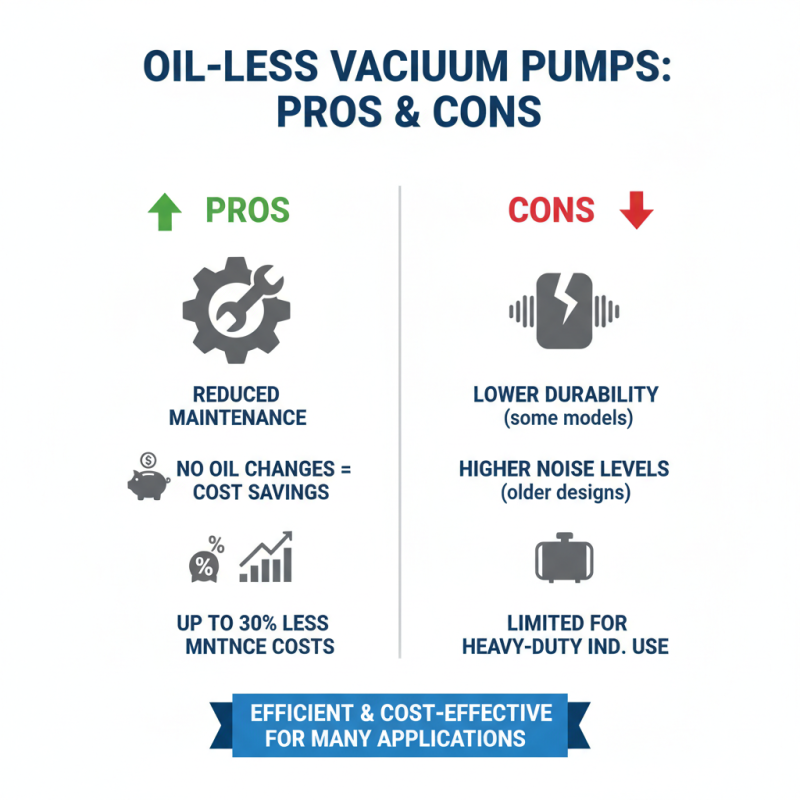

Advantages and Disadvantages of Using Oil Less Vacuum Pumps

Oil-less vacuum pumps, while popular, have their own set of pros and cons. One significant advantage is reduced maintenance. These pumps often don’t require oil changes, saving time and costs. According to a recent industry report, companies can save up to 30% on maintenance costs compared to oil-lubricated alternatives. This efficiency appeals to businesses focused on lowering operational costs.

However, oil-less vacuum pumps also face limitations. They typically operate at higher temperatures, which can affect performance. This higher temperature can lead to wear and tear, potentially shortening the pump's lifespan. Some users report noise levels that can be bothersome, as these pumps tend to be louder than their oil-lubricated counterparts. In fact, noise complaints contribute to 20% of service calls for oil-less models.

While the upfront costs may be lower, the long-term performance requires consideration. Users may find themselves needing replacements sooner than expected. Additionally, the lack of lubrication can lead to lower efficiency, especially in high-demand environments. As with any technology, weighing the immediate benefits against potential long-term drawbacks is crucial.

Maintenance and Care Tips for Oil Less Vacuum Pumps

Oil-less vacuum pumps are a great choice for many applications. They rely on mechanical principles instead of oil for lubrication. This design makes them cleaner and easier to maintain. However, proper care is essential for optimal performance and longevity.

Regularly check the pump filters. Dirty filters can reduce efficiency. Clean them according to the manufacturer's guidelines. Some users forget this step. A quick check can save you from bigger issues later.

Monitor the pump's temperature during operation. If it runs too hot, it may indicate a problem. Ensure there’s adequate ventilation around the unit. Overheating can lead to premature wear. Don’t overlook any unusual noises. They can be early signs of trouble. Addressing these can prevent costly repairs.

Always handle the pump gently. Avoid dropping or jolting it. Even minor impacts can affect its performance. Keeping the pump in a stable location is key. A little attention can go a long way in maintaining its efficiency.

Oil Less Vacuum Pump Performance Comparison

Related Posts

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

How to Choose the Right Oil Vacuum Pump for Your Needs?

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications