Top Factors to Consider When Choosing a High Vacuum Pump for Your Needs

Choosing the right high vacuum pump is crucial for various industrial and research applications, where maintaining a low pressure environment is essential for optimal performance. A high vacuum pump not only impacts the efficiency and reliability of processes such as material deposition, vacuum packaging, or research experiments, but also influences the overall cost-effectiveness of operations. Thus, understanding the key factors to consider when selecting a high vacuum pump is paramount for ensuring that it meets specific requirements and functions at maximum efficiency.

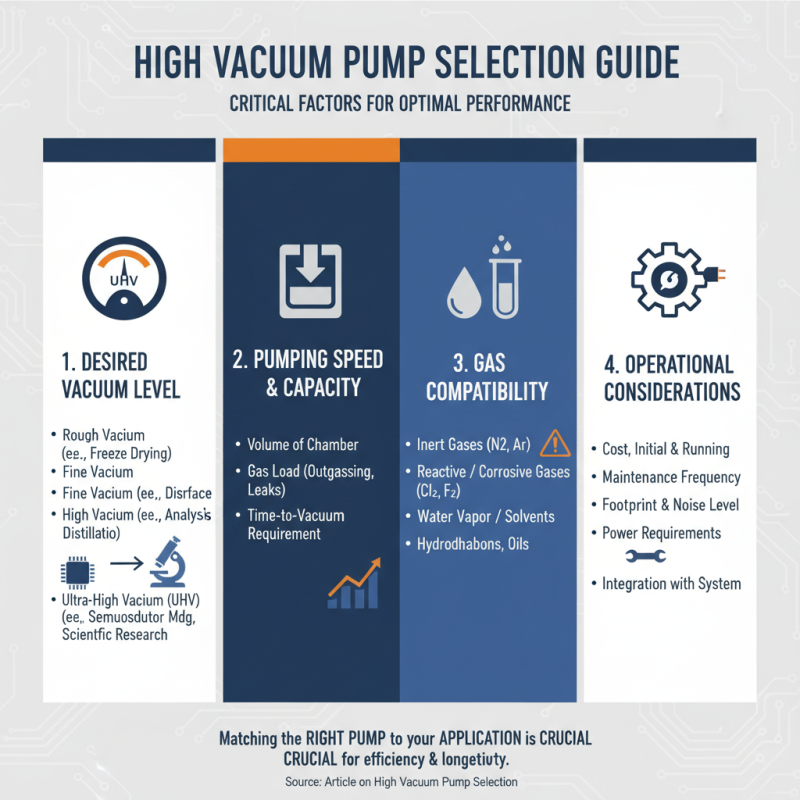

When evaluating a high vacuum pump, several considerations come into play, including the desired vacuum level, the type of gases to be pumped, flow rate requirements, and compatibility with existing systems. The specific application will determine the appropriate characteristics needed from the pump, such as its pumping speed, ultimate pressure, and chemical resistance. Additionally, factors such as maintenance, operational costs, and the physical space available for installation should also be carefully assessed to make an informed decision. With so many variables involved, a comprehensive understanding of these factors will enable users to select a high vacuum pump that aligns perfectly with their operational demands and expectations.

Key Performance Specifications of High Vacuum Pumps

When selecting a high vacuum pump, understanding key performance specifications is essential to ensure it meets your specific requirements. One of the most critical specifications to consider is the ultimate vacuum level, which indicates how low the pressure can be reduced in the system. The lower the ultimate vacuum, the more effective the pump is for applications that require specific and stringent vacuum levels.

Another important factor is the pumping speed, measured in liters per second (L/s) or cubic feet per minute (CFM). This specification defines how quickly the pump can evacuate a chamber and is vital for processes that demand fast turnaround times. A high pumping speed can significantly reduce the time needed for vacuum attainment, but it is important to balance speed with the type of gases being pumped, as different gas compositions can affect performance.

Tips: When choosing a high vacuum pump, pay attention to the compatibility of materials with the substances involved in your applications. Additionally, consider the maintenance and operational costs over time. Regular maintenance can enhance the longevity and performance of your pump, ensuring reliable operation for your needs.

Types of High Vacuum Pumps: Pros and Cons

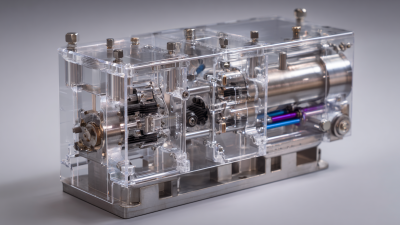

When selecting a high vacuum pump, it's essential to understand the different types available, each with its unique advantages and disadvantages. The primary categories are rotary vane pumps, diaphragm pumps, and turbomolecular pumps. Rotary vane pumps are known for their reliability and efficiency, especially in applications requiring deep vacuum levels (around 10^-3 to 10^-5 Torr). According to the Vacuum Technology and Coating journal, rotary vane pumps can achieve a pumping speed of over 100 m³/h, making them suitable for various industrial environments.

On the other hand, diaphragm pumps are often favored for applications where oil-free operation is crucial. They can efficiently reach vacuum levels around 10^-3 Torr but may not handle high throughput as effectively as rotary vane pumps. A study from the International Journal of Vacuum Science indicated that diaphragm pumps are preferred in environments sensitive to contamination, such as in the semiconductor industry, where the risks associated with oil vapor can compromise product integrity.

Lastly, turbomolecular pumps represent the pinnacle of high vacuum technology, capable of achieving pressures lower than 10^-9 Torr. They employ rapidly spinning blades to impart momentum to gas molecules, making them ideal for ultra-high vacuum applications. However, their complexity and higher cost can be a barrier for some applications. A report from the American Vacuum Society shows that while turbomolecular pumps are gaining popularity in research facilities, careful consideration must be given to their operational requirements, including the need for backing pumps and the sensitivity to vibrations. Each type of pump must be assessed against specific operational requirements to ensure optimal performance for the intended application.

High Vacuum Pumps Comparison: Types and Performance Factors

Factors Influencing Pump Selection for Specific Applications

When selecting a high vacuum pump for specific applications, several critical factors must be assessed to ensure optimal performance. One of the primary considerations is the desired level of vacuum, as this directly impacts the pump's efficiency and effectiveness. Applications such as semiconductor manufacturing or scientific research may require ultra-high vacuum (UHV) capabilities, while other tasks might only need a rough vacuum. Understanding the precise vacuum level needed for your process will help narrow down suitable pump types.

Another influential factor is the nature of the gases or vapors being handled. Different pumps have varying degrees of compatibility with specific substances, which can affect both efficiency and longevity. For instance, some applications may involve corrosive or reactive gases that demand pumps with specialized materials to prevent damage. Additionally, the pumping speed and capacity should match the volume of gas being evacuated to maintain an effective throughput.

Tips: Always consider the maintenance requirements of the pump you choose. Some high vacuum pumps necessitate more frequent servicing, which can impact operational downtime. Evaluate the cost of replacement parts and the ease of access to servicing when making your decision. Furthermore, consult with professionals in the field to gain insights into the best practices for your specific application, as their experience can provide valuable guidance in selecting the right pump.

Maintenance and Longevity Considerations for Vacuum Pumps

When selecting a high vacuum pump, maintenance and longevity are crucial factors that can significantly impact the overall performance and efficiency of your system. Regular maintenance routines, including checking for leaks, monitoring oil levels, and ensuring filters are clean, can help prevent unexpected downtimes and prolong the life of the pump. Establishing a schedule for these maintenance tasks not only ensures optimal operation but also helps identify potential issues before they escalate, minimizing costly repairs or replacements in the future.

Additionally, the materials and construction of the vacuum pump itself play an essential role in its longevity. Pumps constructed from corrosion-resistant materials can withstand harsh environments, reducing wear and tear over time. Furthermore, understanding the operating conditions and selecting a pump that can handle variations in temperature, pressure, and chemical exposure is vital for maintaining its functionality. Proper training for personnel operating the pump can also enhance its lifespan, as skilled users are better equipped to recognize problems and carry out maintenance procedures effectively.

Budgeting: Cost vs. Quality in High Vacuum Pump Selection

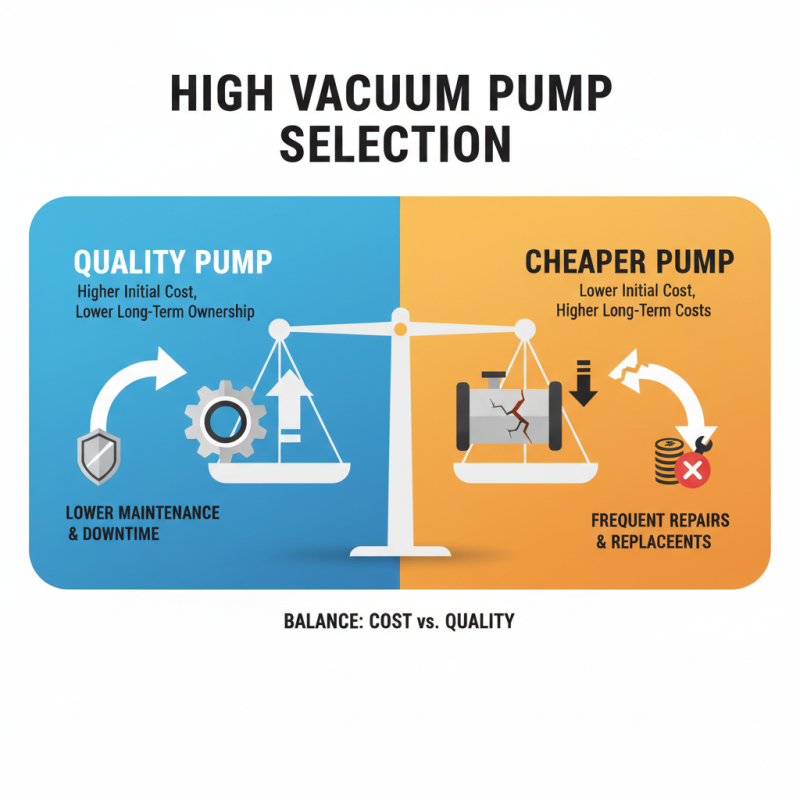

When selecting a high vacuum pump, one of the primary considerations is the balance between cost and quality. Budget constraints often lead buyers to prioritize lower prices, but this can result in compromised performance and durability. Investing in a quality high vacuum pump may require a more considerable upfront expense, yet it can lead to long-term savings by minimizing maintenance costs and potential operational downtime. Cheaper models might not withstand rigorous use, ultimately needing replacement sooner, which can offset any initial savings.

Moreover, the intended application of the pump significantly influences this budgeting decision. If the pump is central to critical processes, the benefits of a higher-quality unit—such as reliability, efficiency, and better vacuum capabilities—will outweigh the costs. Conversely, for less demanding tasks, a more economical option might suffice. Therefore, when making a decision, it is essential to analyze the specific requirements closely and assess how quality impacts overall performance and operating costs in the context of your budget. The goal should be to achieve a sustainable investment that meets both immediate operational needs and long-term viability.

Related Posts

-

Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs