Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

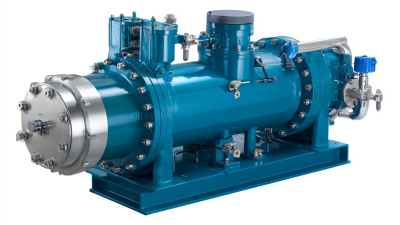

In the realm of industrial operations, the efficiency and reliability of processes are paramount. One critical component that often gets overlooked is the compressor vacuum pump. These pumps play a vital role in maintaining optimal conditions for various applications, ranging from manufacturing to packaging. By creating a vacuum environment, they facilitate the removal of air and moisture, enhancing product integrity and operational efficiency.

The importance of a compressor vacuum pump extends beyond mere functionality; it directly impacts the quality of the final product and the overall productivity of industrial systems. With the ability to support an array of tasks, including material handling, food preservation, and semiconductor fabrication, these pumps serve as the backbone of many industrial processes. In this discussion, we will explore the essential functions of compressor vacuum pumps, their contribution to resource conservation, and how they help industries achieve their operational goals while maintaining high standards of performance and sustainability.

Understanding the Functionality of Compressor Vacuum Pumps in Industry

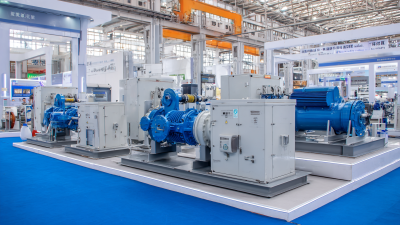

Compressor vacuum pumps play a critical role in enhancing the efficiency of industrial operations by effectively managing air pressure within systems. These pumps create a vacuum that is essential for various processes, such as material handling, packaging, and product drying. According to a report by the Research and Markets, the global vacuum pump market is expected to reach USD 4.3 billion by 2026, highlighting the increasing acknowledgment of these pumps' importance in industrial settings.

The functionality of compressor vacuum pumps extends to applications like semiconductor manufacturing, where precision and control over the vacuum environment are paramount. Data from the International Society of Automation indicates that implementing high-quality vacuum pumps can improve production efficiency by up to 30%, significantly reducing cycle times and minimizing waste. Furthermore, in the food and beverage industry, vacuum packaging facilitated by these pumps helps in extending shelf life and maintaining product quality, substantially impacting profitability.

As industries continue to evolve with advancements in technology, the demand for reliable and efficient compressor vacuum pumps is set to rise. These pumps not only streamline processes but also contribute to sustainable practices by reducing energy consumption and minimizing environmental impact, making them indispensable in modern industrial applications.

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

| Feature | Description | Importance |

|---|---|---|

| Efficiency | Compressor vacuum pumps enhance operational efficiency by reducing energy consumption. | Lower energy costs and improved productivity. |

| Process Control | They provide precise control over vacuum levels in manufacturing processes. | Ensures product quality and consistency. |

| Versatility | Used across various industries including food processing, pharmaceuticals, and packaging. | Adapts to different industrial applications and requirements. |

| Maintenance | Modern vacuum pumps require less maintenance due to technological advancements. | Reduces downtime and operational disruptions. |

| Safety | Provide safer working environments by eliminating hazardous airborne particles. | Protects employee health and regulatory compliance. |

Key Benefits of Using Compressor Vacuum Pumps for Operational Efficiency

Compressor vacuum pumps play a pivotal role in enhancing operational efficiency across various industrial sectors. One of the key benefits of these pumps is their ability to create a reliable vacuum environment, which is essential for processes such as packaging, drying, and material handling. By maintaining a consistent vacuum level, manufacturers can prevent contamination and ensure product integrity, ultimately leading to higher quality outputs. Furthermore, the efficient removal of air and moisture reduces the risk of spoilage, extending the shelf life of products and minimizing waste.

Another significant advantage of utilizing compressor vacuum pumps is their energy efficiency. These pumps are designed to operate with minimal energy consumption while delivering high performance. By optimizing energy use, industries can lower their operational costs and reduce their carbon footprint. Additionally, many modern vacuum systems incorporate advanced technology that allows for better monitoring and control, resulting in improved process management. This not only enhances productivity but also contributes to a more sustainable industrial operation, making compressor vacuum pumps an indispensable component in achieving efficiency and effectiveness in production processes.

Applications of Compressor Vacuum Pumps in Various Industrial Sectors

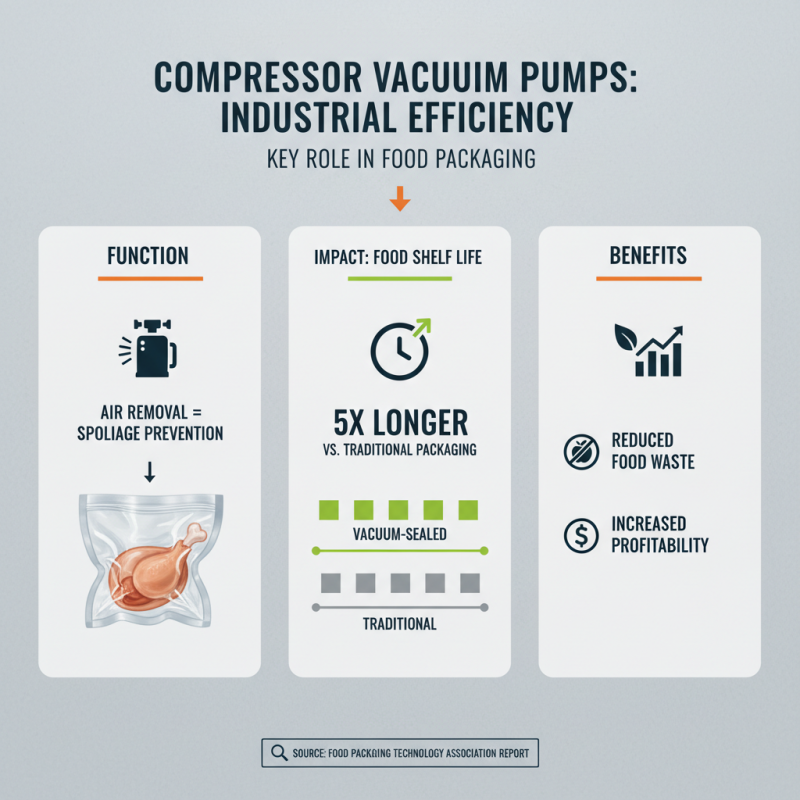

Compressor vacuum pumps play a pivotal role in enhancing efficiency across various industrial sectors. In the food packaging industry, for instance, the application of vacuum pumps facilitates the removal of air that can cause spoilage, thereby extending shelf life significantly. A report from the Food Packaging Technology Association highlights that vacuum-sealed products can last up to five times longer than those packaged using traditional methods. This not only reduces food waste but also enhances the overall profitability of operations.

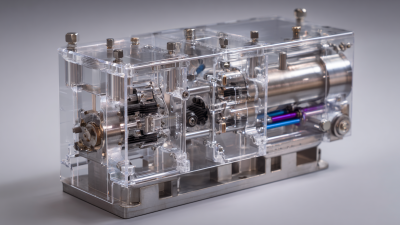

In the pharmaceutical industry, the importance of compressor vacuum pumps cannot be overstated. They are essential in processes such as freeze-drying and solvent recovery, where maintaining the integrity of sensitive compounds is crucial. According to data from the International Society for Pharmaceutical Engineering, approximately 80% of drug formulations require vacuum technology for optimal production. The precision offered by these pumps improves yield and minimizes contamination risk, which is critical in producing high-quality pharmaceuticals.

Moreover, in the semiconductor manufacturing sector, vacuum pumps are vital for creating the clean environments necessary for chip production. The Semiconductor Industry Association reports that advancements in vacuum technology have been instrumental in achieving the ultra-high vacuum levels required for lithography processes, which are the backbone of modern electronics. This underscores the versatility of compressor vacuum pumps in various industries, where they not only support operational efficiency but also drive innovation and quality.

Maintenance Practices to Ensure Longevity of Compressor Vacuum Pumps

Regular maintenance practices are critical to ensuring the longevity and efficiency of compressor vacuum pumps in industrial operations. One of the key aspects of maintenance involves routine inspections, where technicians should check for any signs of wear or damage in components such as seals, valves, and bearings. Identifying potential issues early can prevent costly breakdowns and extend the lifespan of the equipment. Furthermore, maintaining appropriate lubrication levels is crucial. Oils and lubricants play a vital role in reducing friction and heat, which, if unchecked, can lead to accelerated degradation of the pump.

Another important practice involves monitoring the pump's performance metrics, such as pressure levels and flow rates. By analyzing these parameters periodically, operators can detect deviations from normal functioning that may indicate underlying issues. Cleanliness is also essential; keeping the pump and its surrounding area free from contaminants helps in maintaining optimal performance. Additionally, implementing a regular schedule for replacing filters and oil can significantly enhance the reliability and efficiency of compressor vacuum pumps, ultimately contributing to smoother industrial operations.

Future Innovations in Compressor Vacuum Pump Technology for Industry

As industries evolve, the demand for innovative solutions in compressor vacuum pump technology continues to grow. Recent reports indicate that the global market for vacuum pumps is expected to reach approximately $7 billion by 2027, growing at a CAGR of 5.5% from 2020 to 2027. This surge is driven by the increasing need for energy-efficient operations in manufacturing sectors, including food processing, pharmaceuticals, and semiconductor production. Future innovations focus on enhancing energy efficiency, reliability, and automation, enabling manufacturers to optimize their systems further.

One of the emerging trends is the integration of IoT technology within compressor vacuum pumps. By utilizing advanced sensors and AI algorithms, these systems can predict maintenance needs, monitor operational efficiency in real-time, and significantly reduce downtime. Moreover, advancements in materials science are leading to the development of lighter and more durable components, which can enhance the overall performance and lifespan of vacuum pumps.

With sustainability becoming a central theme, innovations aimed at reducing energy consumption could see efficiency levels surpassing 80% in the coming years, further cementing the role of these technologies in efficient industrial operations.

Related Posts

-

Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications