Why Choosing the Right Vacuum Pump Manufacturer Matters for Your Business?

Choosing the right vacuum pump manufacturer is crucial for any business relying on vacuum technology. The performance of your systems largely depends on the quality of the pumps. A high-quality vacuum pump increases efficiency and minimizes downtime. This directly impacts your productivity and profitability.

In contrast, partnering with an unreliable vacuum pump manufacturer can lead to problems. You may face frequent breakdowns and costly repairs. These unexpected issues can stall production lines and slow down your operations. Moreover, a poor choice can affect product quality. This can harm your reputation in the market.

It’s important to invest time in research when selecting a manufacturer. Consider their history, customer reviews, and service support. Not all manufacturers are the same, and sometimes the most popular one isn’t necessarily the best fit for your needs. Reflecting on these factors is essential for long-term success.

Understanding Vacuum Pumps: Types and Applications for Businesses

Vacuum pumps are essential tools in various industries. They create a vacuum by removing air and other gases from a sealed chamber. Understanding the types of vacuum pumps can help businesses choose the right one for their applications. There are several types, including positive displacement pumps and dynamic pumps. Positive displacement pumps are often used in food packaging and medical applications. Dynamic pumps excel in applications requiring high speeds and low pressures, such as semiconductor manufacturing.

Different industries have unique needs. For example, the semiconductor industry utilizes dry vacuum pumps to prevent contamination. A 2022 industry report indicated that the global vacuum pump market is projected to reach $3.75 billion by 2026. This growth reflects the increasing demand for efficient manufacturing processes. Businesses should consider how vacuum pumps impact productivity and product quality. Poor choices can lead to inefficiencies and high operational costs. Proper research is vital.

Many businesses overlook maintenance of vacuum pumps. Neglecting this can result in decreased performance. Regular checks are necessary to ensure optimal operation. The right manufacturer can provide support and maintenance guidelines. Selecting the right vacuum pump manufacturer is critical. It can affect overall performance and long-term success.

Why Choosing the Right Vacuum Pump Manufacturer Matters for Your Business?

| Type of Vacuum Pump | Application | Typical Industries | Efficiency Rating | Cost Range (USD) |

|---|---|---|---|---|

| Rotary Vane Pump | General-purpose vacuum | Manufacturing, Lab Research | 85-90% | $300 - $1,200 |

| Diaphragm Pump | Chemical processing | Pharmaceuticals, Food Industry | 90-95% | $500 - $2,000 |

| Scroll Pump | High vacuum applications | Semiconductors, Electronics | 85-95% | $800 - $4,000 |

| Turbo Molecular Pump | Ultra high vacuum | Research labs, Particle Physics | 90-99% | $2,500 - $10,000 |

| Liquid Ring Pump | Pumping vapors and gases | Wastewater, Oil and Gas | 80-90% | $1,000 - $4,500 |

Key Factors to Consider When Selecting a Vacuum Pump Manufacturer

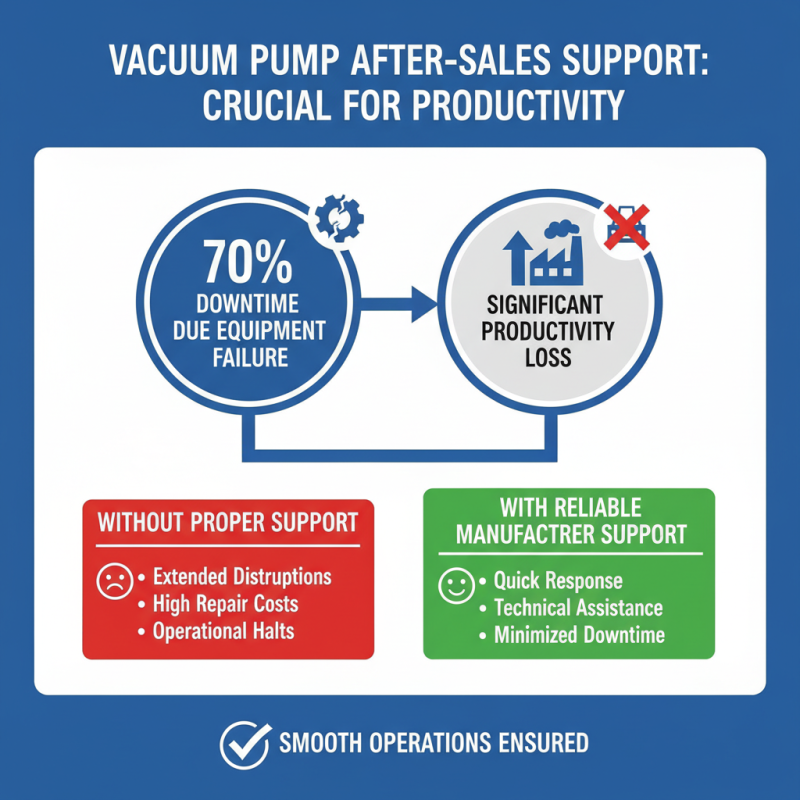

When selecting a vacuum pump manufacturer, it’s crucial to consider several key factors. Reliability is one of the most essential aspects. According to industry data, approximately 70% of operational downtime is due to equipment failure. This can be devastating for production lines. Thus, businesses must evaluate the reliability track record of potential manufacturers.

Another important factor is the material quality of the pumps. High-quality materials enhance durability. Poor material choices can result in increased maintenance costs. Moreover, 60% of failures occur due to wear and tear stemming from inferior materials. Each decision can significantly impact your bottom line.

Finally, consider the level of customer support offered by the manufacturer. In a survey conducted among industry professionals, 65% reported that responsive customer service was critical when problems arose. A manufacturer with strong support can help you troubleshoot effectively and minimize downtime. Reflecting on these elements will guide you in making an informed decision that aligns with your business needs.

Factors to Consider When Selecting a Vacuum Pump Manufacturer

Evaluating Manufacturer Reputation and Industry Experience

Choosing the right vacuum pump manufacturer is crucial. The reputation of a manufacturer can significantly impact your business's operational efficiency. A recent industry report revealed that 78% of companies experienced issues due to equipment failures linked to poor-quality pumps. This statistic underlines the importance of selecting a manufacturer with a solid reputation for reliability.

Industry experience also matters. Manufacturers with a long track record often have in-depth knowledge of vacuum technology. According to a study, 65% of firms benefitted from manufacturers with over 20 years of experience. Such companies can offer innovative solutions tailored to your specific needs. However, not all experienced manufacturers are equal. Some may lack updated technology, limiting performance.

Evaluating both reputation and experience is essential. Engaging with manufacturers that have earned industry certifications can provide additional assurance. Yet, many businesses overlook this aspect, risking subpar performance. Relying solely on cost can be misleading and lead to greater expenses down the line. Make informed choices to ensure your operations run smoothly.

The Importance of After-Sales Support and Warranty Options

When selecting a vacuum pump manufacturer, after-sales support is crucial. A recent report highlighted that 70% of companies experience significant downtime due to equipment failure. Without proper support, this can severely impact productivity. A reliable manufacturer provides robust assistance. This includes quick response times and accessible technical help. Such support minimizes disruptions and ensures smooth operations.

Warranty options also play a vital role. A vacuum pump is a long-term investment. Quality warranties indicate the manufacturer's confidence in their product. Reports indicate that users with comprehensive warranty plans save up to 30% on repair costs. However, not all warranties are equal. Some may have hidden clauses that complicate claims. It’s essential to fully understand the terms before making a decision. Many businesses overlook this, risking unexpected costs later.

Manufacturers should clearly outline their support and warranty offerings. This can prevent misunderstandings in the future. Investing time in this research can lead to better choices. Quality after-sales service can extend the lifespan of equipment. When businesses disregard these elements, they often face challenges. Striking the right balance can ultimately influence long-term success.

Cost vs. Quality: Making an Informed Decision for Your Business Needs

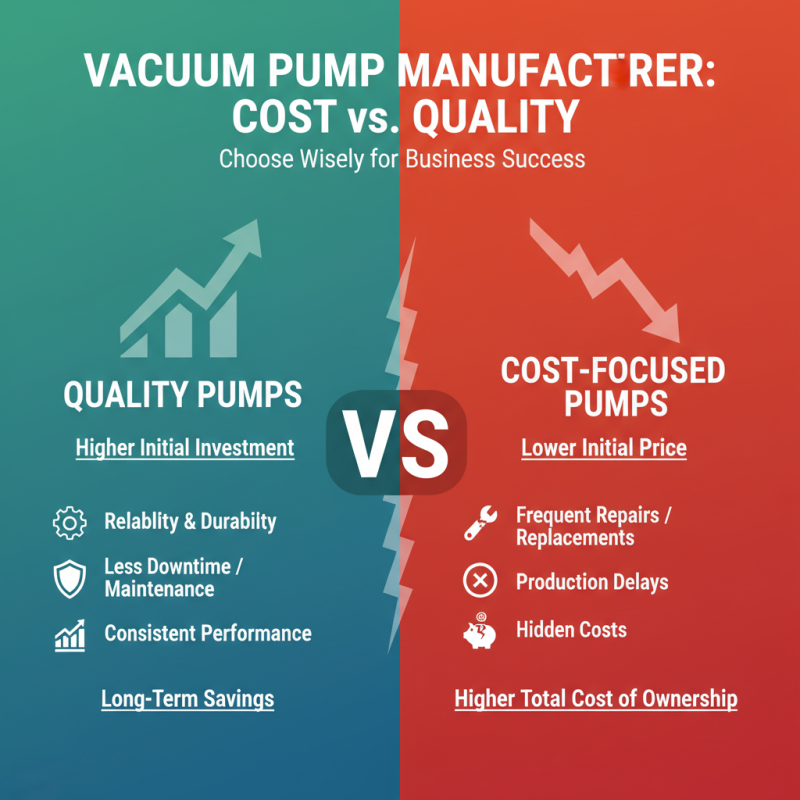

Choosing the right vacuum pump manufacturer is crucial for your business. The decision often hangs between cost and quality. While lower-priced options may seem attractive, hidden costs may arise. An inexpensive vacuum pump may require frequent repairs or replacement. This can lead to downtime and reduced efficiency.

Quality pumps, though pricier, often perform better in the long run. They typically have better warranties and support. A reliable vacuum pump ensures consistency in production. You may save money on operational costs with a high-quality model. However, you need to balance this with your budget constraints.

Reflecting on your business needs is essential. Identify how the vacuum pump will be used. Will it be under heavy use or less? The right choice depends on specific applications. Investing in quality may mean higher upfront costs, but it can lead to greater savings over time. Don’t overlook the impact of a good vacuum pump on your operational excellence.

Related Posts

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

-

Top Factors to Consider When Choosing a High Vacuum Pump for Your Needs

-

2026 How to Choose the Right Vacuum Blower Pump for Your Needs?

-

Top 10 Blower and Vacuum Models of 2023: Efficiency, Power, and User Ratings Reviewed

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications