2026 How to Choose the Right Vacuum Blower Pump for Your Needs?

Choosing the right vacuum blower pump is crucial for many applications. Renowned expert Dr. Jane Simmons states, "Selecting the correct pump can significantly impact efficiency." This advice rings true for businesses across multiple industries.

When selecting a vacuum blower pump, it's essential to assess your specific needs. Consider factors such as airflow, pressure, and the materials used in production. Often, businesses overlook these details, leading to mismatched equipment. Each application has unique requirements that must be met.

Mistakes in selection can be costly. For instance, a pump that is too weak won't perform adequately. On the other hand, an overly powerful pump may consume unnecessary energy. Reflecting on your requirements is key to making the right choice. Exploring various options in the market can help clarify what works best for you.

Understanding Vacuum Blower Pumps: Types and Applications

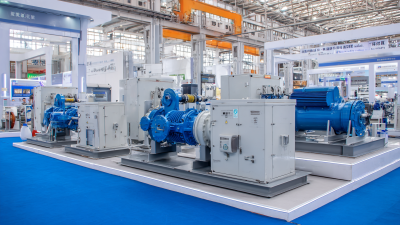

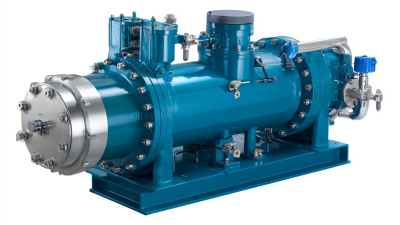

When choosing a vacuum blower pump, understanding the types available is crucial. There are three main categories: positive displacement pumps, regenerative blowers, and liquid ring pumps. Each has unique applications. Positive displacement pumps provide a constant flow, but they can be bulky. This might not suit all spaces. On the other hand, regenerative blowers are lighter and easier to install. However, they often lack the power for heavy-duty tasks.

Liquid ring pumps are effective in various environments. They handle wet and dry applications, showing flexibility. Yet, maintenance can be challenging. Users might face trouble managing the water levels needed for optimal performance. It’s critical to assess the work environment, as certain pumps may not thrive in all conditions.

Applications vary widely, from industrial processes to packaging. Knowing the specific requirements is vital. Not every pump fits every task. For instance, a pump ideal for food processing may not work well in an electronics factory. Evaluating your precise needs will lead to better choices. Misjudgments here can result in costly downtime.

2026 How to Choose the Right Vacuum Blower Pump for Your Needs?

| Type of Pump | Application | Vacuum Range (Torr) | Max Flow Rate (m³/h) | Noise Level (dB) |

|---|---|---|---|---|

| Rotary Vane Pump | Industrial Vacuum Packaging | 0.5 to 1000 | 2-10 | 60-70 |

| Oil-sealed Pump | Laboratory & Research | 1 to 1000 | 5-25 | 55-65 |

| Dry Scroll Pump | Semiconductor Manufacturing | 0.1 to 5 | 10-50 | 50-60 |

| Diaphragm Pump | Pharmaceuticals | 1 to 100 | 0.5-3 | 40-50 |

Key Factors to Consider When Choosing a Vacuum Blower Pump

Choosing the right vacuum blower pump involves several key factors. Understanding your needs is essential. Consider the application you require the pump for. Are you using it in a lab or an industrial setting? The environment can dictate the pump type you need.

When evaluating options, look at performance specifications. Pay attention to airflow rates and vacuum levels. Both impact efficiency. A pump that works well in one context may not perform the same in another. Don't shy away from questioning the technical data. Ask for clarifications on numbers that seem off.

Tips: Check for energy efficiency ratings. A pump that consumes less power can save costs in the long run. Maintenance requirements also matter. Consider how often the pump needs servicing. A high-maintenance pump can lead to disruptions.

Additionally, noise levels should not be overlooked. Some pumps operate quietly, while others are loud. A noisy pump can be distracting in a workplace. Balancing performance and comfort is crucial. Always reflect on how these factors align with your specific needs.

Sizing Your Vacuum Blower Pump for Optimal Performance

When selecting a vacuum blower pump, sizing plays a crucial role. A properly sized pump can enhance efficiency and ensure optimal performance. Consider the application requirements first. Is it for a small workshop or a large industrial setup? The volume of air needed varies significantly between these.

Calculate the required airflow in cubic feet per minute (CFM). This measurement is essential for accurate sizing. Underestimating this value can lead to insufficient suction power. On the other hand, overestimating may cause energy waste. It’s a fine balance that requires thoughtful analysis. Remember, a pump that’s too large can create excess noise and energy expenses.

Also, consider the pressure levels. Different applications have specific vacuum levels. For instance, packaging might need a different level than general clean-up tasks. Take time to assess these needs thoroughly. A pump that operates efficiently is often a result of careful consideration. Reflect on your requirements and the potential for adjustments down the line. Unexpected issues may arise, leading to the need for changes and enhancements.

Assessing Energy Efficiency and Maintenance Requirements

Choosing the right vacuum blower pump is key to optimizing operational efficiency. Energy efficiency must be a top consideration. According to a 2022 report by the Global Energy Efficiency Forum, the vacuum pump sector accounts for about 15% of total industrial energy use. Therefore, selecting a model that minimizes energy consumption can lead to substantial cost savings over time. Look for pumps with high-efficiency motors and variable speed drives, as these can enhance overall performance.

Maintenance requirements are another critical factor. Regular upkeep ensures longevity and reliability. A study by the Institute of Mechanical Engineers indicated that poorly maintained pumps can lose up to 20% in efficiency. Pay attention to service intervals and the complexity of replacements. Some systems can be prone to wear and tear, leading to more frequent repairs. Assess your operational environment—dusty or humid settings may require a more robust solution. Even seemingly minor issues can escalate, resulting in downtime.

While efficiency and maintenance are essential, the perfect balance might not be easy to achieve. Costs can creep up when proper maintenance isn't prioritized. Understanding energy use and maintenance patterns can help prevent unexpected failures. This balancing act deserves careful consideration to ensure optimal performance and cost-effectiveness.

2026 Vacuum Blower Pump Energy Efficiency Comparison

This chart illustrates the energy efficiency ratings of different types of vacuum blower pumps. The ratings are measured in terms of energy consumed (kWh) versus the airflow produced (CFM). It is crucial to choose a pump that balances energy efficiency with your specific airflow needs for optimal performance.

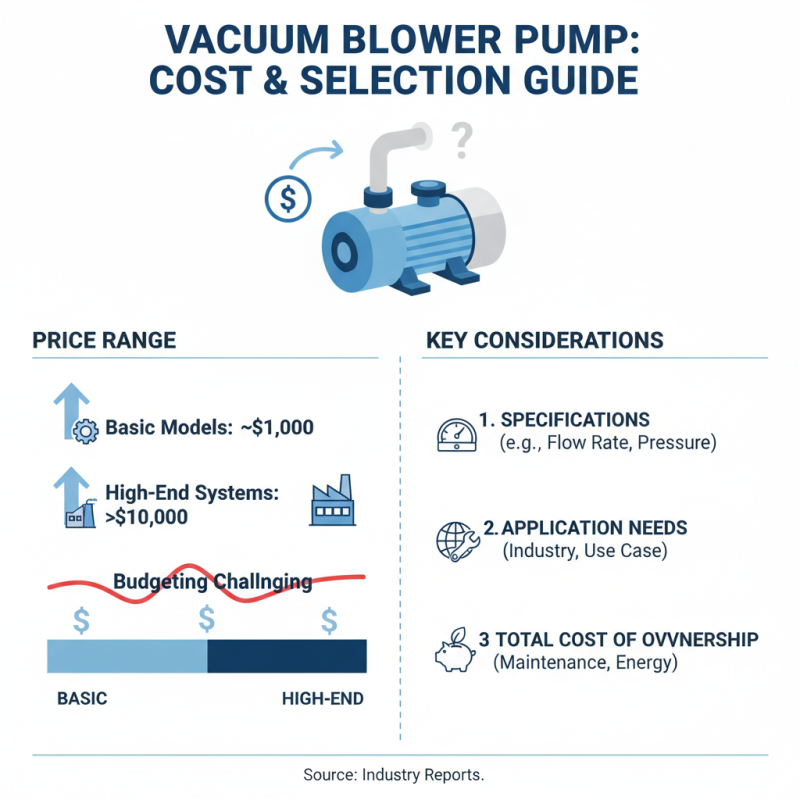

Cost Analysis: Budgeting for Your Vacuum Blower Pump Selection

When selecting a vacuum blower pump, cost is a significant factor. Industry reports indicate that prices can vary widely. Basic models may start around $1,000, while high-end systems can exceed $10,000. This wide range can make budgeting challenging. Always consider the specifications you need alongside the price tag.

A common mistake is underestimating operational costs. Maintenance, energy consumption, and repairs add up. For example, a poorly maintained pump may double electricity consumption, leading to higher bills. A recent study highlights that maintenance can account for up to 30% of total ownership costs. It's essential to factor these elements into your budget planning.

Tip: Gather multiple quotes from suppliers. This helps you understand market prices and find the best deal. Evaluate lifetime costs rather than just initial expenses.

Tip: Consider energy efficiency ratings. Efficient models may have a higher upfront cost, but savings on electric bills can make them more cost-effective long-term.

Keep in mind, the cheapest option may not always be ideal. Reflect on your specific needs and the total cost of ownership. This approach ensures a well-informed decision, aligning performance with budget constraints.

Related Posts

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications