How to Choose the Right Oil Vacuum Pump for Your Needs?

Choosing the right oil vacuum pump can feel overwhelming. There are many types and features to consider. An oil vacuum pump is essential for various applications, from automotive repairs to industrial processes.

When selecting one, think about your specific needs. Are you working with small machinery or large equipment? Different pumps suit different tasks. For example, a smaller pump is often ideal for home workshops. In contrast, industrial settings may require powerful models capable of handling larger volumes.

However, it’s crucial to reflect on your choices. Some pumps may seem appealing but lack necessary features. Reliability and performance often matter more than price. Finding the best balance between quality and cost is vital for long-term satisfaction. Don't rush the decision; take the time to assess your requirements carefully.

Understanding the Basics of Oil Vacuum Pumps

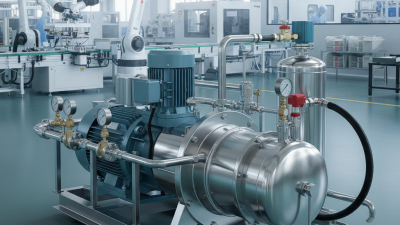

Oil vacuum pumps are essential tools in various industries. Understanding their basics is crucial for effective use. These pumps create a vacuum by removing air and vapor from a sealed environment. They operate using a range of mechanisms, including rotary vane and diaphragm methods. This understanding helps in selecting the right pump for different applications.

The market for oil vacuum pumps is growing. According to a recent industry report, the global vacuum pump market was valued at $3.54 billion in 2020. It is expected to reach $5.29 billion by 2028, with a compound annual growth rate of 5.12%. This data reflects the increasing demand for efficient oil extraction processes. The choice of pump significantly influences operational efficiency and product quality.

Quality and performance should guide your selection process. Each application might require specific pump characteristics. Consider factors like capacity, operating pressure, and compatibility with fluids. Some pumps handle high temperatures while others are better for specific viscosity levels. Not every pump will fit all needs. Assessing these criteria carefully prevents costly mistakes. Detailed research into pump specifications often reveals surprising limitations that should be addressed.

Identifying Your Specific Requirements and Applications

When selecting an oil vacuum pump, consider your specific requirements carefully. Different applications demand various functionalities. Are you working with large volumes or just small batches? The pump’s capacity must match your production needs. If you overlook this detail, it could lead to inefficiencies.

Next, think about the oil viscosity you will handle. Some pumps are better suited for thicker oils, while others perform well with lighter fluids. This distinction can vastly affect performance. You might need to experiment to find the right fit. Size also matters. A pump that is too big takes up unnecessary space, while a small one may struggle with your workload.

Don’t forget about maintenance and durability. Choose a model that offers reliable service. Some pumps may require more frequent maintenance than others. This can lead to increased downtime. It’s wise to assess long-term costs rather than just the initial price. Ensure that the pump’s features align with your operational goals.

How to Choose the Right Oil Vacuum Pump for Your Needs?

| Pump Type | Max Vacuum (inHg) | Flow Rate (CFM) | Power Source | Ideal Applications |

|---|---|---|---|---|

| Single Stage | 25 | 3 | Electric | Automotive, HVAC |

| Two Stage | 29 | 4.5 | Electric | Industrial, Commercial |

| Portable | 23 | 2 | Battery | Fieldwork, Service Trucks |

| Vacuum Booster | 28 | 5 | Electric | Research, Laboratories |

Evaluating Pump Specifications: Flow Rate, Vacuum Level, and Capacity

Choosing the right oil vacuum pump involves careful evaluation of its specifications. Three critical factors are flow rate, vacuum level, and capacity. According to a recent industry report, optimal flow rates can range from 2 to 20 CFM, depending on your application. For example, automotive applications typically require pumps with flow rates above 10 CFM for efficient oil extraction.

Vacuum level is equally vital. Most oil vacuum pumps achieve levels between 25 to 29 inches of mercury. A vacuum level of 28 inches is standard for effective oil removal. However, a higher vacuum can create issues. It may lead to excessive wear or seal failures if not controlled properly. Finding the right balance is crucial.

Capacity covers the amount of oil a pump can handle before needing maintenance. Many pumps hold between 5 to 10 liters. But, some enthusiasts report that smaller capacities lead to frequent emptying, which might slow down projects. Consider how often you'll need maintenance when selecting a pump. A larger tank might offer convenience but also requires more space for storage. Always weigh these factors against your specific needs.

Oil Vacuum Pump Specifications Comparison

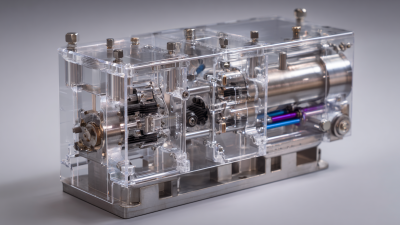

Comparing Different Types of Oil Vacuum Pumps and Their Features

When choosing an oil vacuum pump, understanding the types available is crucial. There are several options to consider, each with distinct features.

Rotary vane pumps are popular for their efficiency. They provide a steady vacuum but may require regular maintenance.

Diaphragm pumps are quieter and suitable for smaller tasks. However, they may not reach the same vacuum levels and could be less durable.

Consider the application's specific needs. If large volumes are involved, a two-stage pump might be advantageous.

These pumps provide a higher vacuum and are often used in industrial settings. On the other hand, a single-stage pump might suffice for lighter applications.

Remember that portability can also play a role. Some pumps are designed for easy transport, making them ideal for fieldwork.

It's important to reflect on your usage. A powerful pump may seem appealing, but consider the energy costs. Operating such machines can lead to significant energy consumption.

Also, filter replacement may be frequent, increasing operational costs. Weighing the pros and cons of each type will help you make the right choice for your specific needs.

Maintenance Considerations for Longevity and Performance

Maintaining an oil vacuum pump is crucial for optimal performance and longevity. Regular maintenance helps prevent costly repairs and inefficient operation. First, always check the oil level. Low oil levels can lead to damage. Change the oil according to the manufacturer’s guidelines. Using clean, suitable oil will ensure better lubrication.

Next, inspect the filters. Replace them frequently to avoid clogs. Dirty filters can strain the pump. Pay attention to unusual noises during operation; they may indicate a problem. Listen closely and act quickly. Sometimes, a small issue can escalate.

Regularly examine hoses and connections for leaks. Even a small leak can hurt performance. Keep the pump clean. Dust and debris can cause overheating. Consider creating a maintenance schedule. Track any irregular changes. Reflect on what worked and what didn't. Adjust your routine as needed to enhance performance.

Related Posts

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications