2026 How to Choose the Right Vacuum Pump Manufacturer for Your Needs?

Choosing the right vacuum pump manufacturer can significantly impact your operations. The global vacuum pump market is expected to reach $3.67 billion by 2026, growing at a CAGR of 5.2% from 2021 to 2026. Selecting the right partner is critical for maximizing efficiency and reliability in your processes.

Michael Thompson, an industry expert at Vacuum Solutions Inc., emphasized, "Choosing a manufacturer isn’t just about price; it’s about long-term performance." This highlights the importance of considering quality and service support. With many manufacturers available, it can be challenging to differentiate between them. Factors such as specialization, technology, and customer service need careful evaluation.

Many businesses rush through this decision. They may overlook crucial aspects like warranty, after-sales service, and compatibility with existing systems. A hasty choice can lead to increased downtime and higher operational costs. Companies should take time to reflect on their specific needs before committing to a vacuum pump manufacturer.

Understanding Different Types of Vacuum Pumps and Their Applications

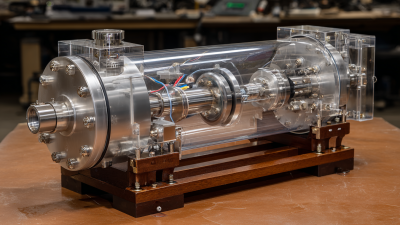

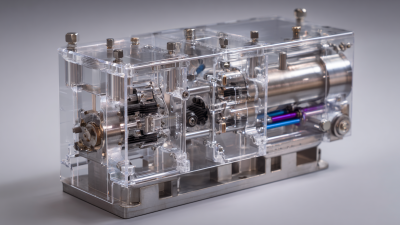

Vacuum pumps come in various types, each designed for specific applications. Understanding these differences is crucial for making an informed choice. For instance, rotary vane pumps are commonly used for general vacuum applications. They provide moderate vacuum levels and are relatively easy to maintain. However, they may not be ideal for high-purity processes due to potential oil contamination.

On the other hand, diaphragm pumps offer a cleaner alternative. They are oil-free and suitable for applications requiring high purity. These pumps can handle corrosive gases, making them effective for certain laboratory uses. However, they may struggle to achieve the same vacuum levels as rotary vane pumps. This limitation requires careful consideration of application needs.

Consider also the overall efficiency of the pump. Some models consume more energy than others. A pump that appears cheap upfront might lead to higher long-term costs. Always assess warranty and service options. A company with poor support can lead to frustrations down the line. When choosing a manufacturer, research their reputation in the industry. A well-regarded manufacturer often reflects a commitment to quality and reliability.

Different Types of Vacuum Pumps and Their Applications

This bar chart illustrates the various types of vacuum pumps and their common applications, showcasing the most suitable options for different industrial needs.

Key Factors to Consider When Selecting a Vacuum Pump Manufacturer

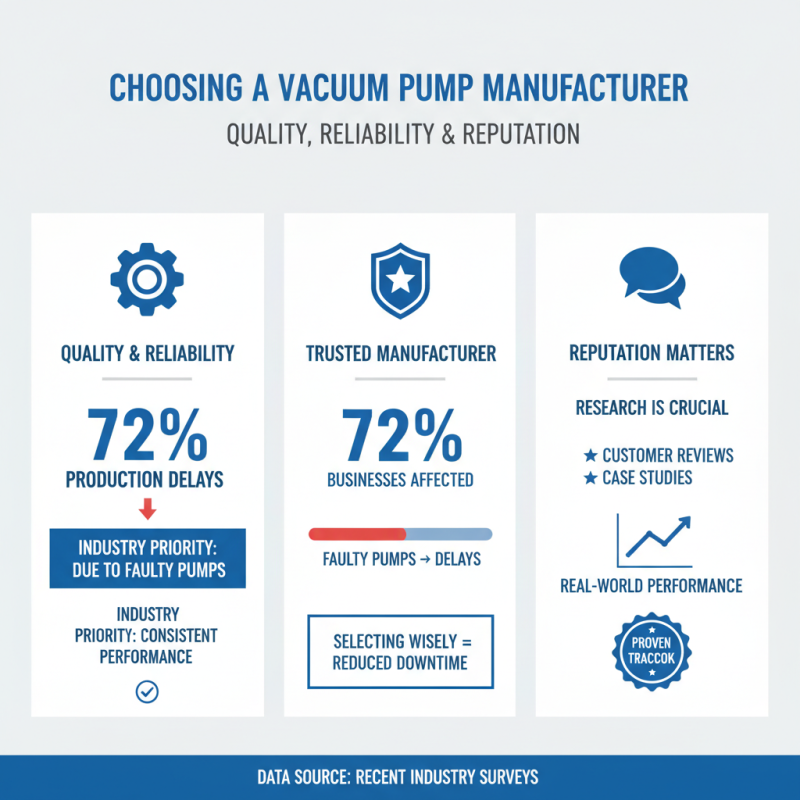

Choosing the right vacuum pump manufacturer requires careful consideration. Industry reports suggest that quality and reliability are top priorities for users. According to a recent survey, 72% of businesses reported production delays due to faulty pumps. This statistic underscores the importance of selecting a trusted manufacturer. Analyzing their reputation is essential. Look for customer reviews and case studies that demonstrate real-world performance.

Cost is another critical factor. A lower price can be tempting, but it might compromise quality. A study indicates that investing 20% more in a reliable pump can yield up to 50% more productivity over time. Evaluate the total cost of ownership. Maintenance, warranty options, and operational efficiency significantly impact long-term expenses.

Additionally, consider the manufacturer’s support services. A responsive technical support team can save time and reduce downtime. Many users express frustration when they cannot reach help quickly. Unresolved issues can escalate, leading to costly mistakes. Ensure that the manufacturer provides adequate training and resources. This can streamline operations and enhance overall efficiency. Taking a comprehensive approach will lead to more informed decisions.

Evaluating Manufacturer Experience and Industry Reputation

When selecting a vacuum pump manufacturer, experience plays a vital role. Look for companies that have been in the industry for several years. Longevity often means stability and expertise. A manufacturer with a strong history is likely to understand market demands. They may have faced challenges and adapted over time. This adaptability can lead to better product quality. Yet, not all experienced manufacturers meet modern standards. Some may cling to outdated practices. You must investigate whether they innovate alongside their experience.

Industry reputation also matters significantly. A manufacturer’s standing reflects their commitment to quality. Check online reviews and customer testimonials. They reveal how previous clients feel about their products. However, don't rely solely on star ratings. Consider the context behind these reviews. A few negative comments might indicate a larger issue. But, some critiques may be unwarranted or outdated. Engaging directly with previous customers could provide deeper insights. Ask them about their experiences and any issues faced. Gathering diverse opinions will help you make an informed decision.

Assessing Product Quality and Performance Standards of Vacuum Pumps

Choosing the right vacuum pump manufacturer involves careful evaluation of product quality and performance standards. Different applications require various levels of vacuum and pump performance. A recent industry report indicates that 75% of users encounter issues caused by subpar pump quality. This emphasizes the importance of selecting a reputable manufacturer.

When assessing vacuum pumps, consider factors like efficiency, noise levels, and durability. High-quality pumps typically have lower failure rates and longer life spans. A study shows that pumps with superior materials and design reduce maintenance costs by up to 30%. However, even trusted brands can produce less effective models, leading to potential inefficiencies.

Another crucial aspect is performance testing and certifications. Manufacturers should provide clear data on their product's capabilities under real-world conditions. It’s important to question claims made in marketing materials. Real users often report discrepancies between advertised performance and actual results. Ensuring that the pump meets industry standards can protect you from costly mistakes.

Exploring Customer Support and After-Sales Service from Manufacturers

When considering a vacuum pump manufacturer, customer support is critical. A strong service team can make all the difference. Quick responses to inquiries are a sign of a solid manufacturer. You should feel valued as a customer.

After-sales service plays a vital role as well. Manufacturers should offer easy access to spare parts and maintenance services. A comprehensive warranty can provide peace of mind. However, some companies may falter in this area, leaving customers frustrated. It’s worth exploring reviews to see others’ experiences.

Moreover, direct communication with the manufacturer can shed light on their support quality. You might ask questions about troubleshooting or parts replacement. If the responses are unclear, it may raise concerns. Reflect on these points as they can reveal how much a manufacturer cares about its customers.

Related Posts

-

Unveiling the Secrets: How High Vacuum Pumps Revolutionize Scientific Research and Industry

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Exploring Air Vacuum Innovations at the 138th Canton Fair 2025

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals