How to Choose the Right Vacuum Compressor for Your Industrial Needs

Choosing the right vacuum compressor for your industrial needs is a crucial decision that can significantly impact your operational efficiency and cost-effectiveness. Vacuum compressors play a vital role in various applications, including packaging, material handling, and pharmaceutical processes, among others. With an extensive array of models and specifications available on the market, making an informed choice requires a clear understanding of your specific requirements and the available technologies.

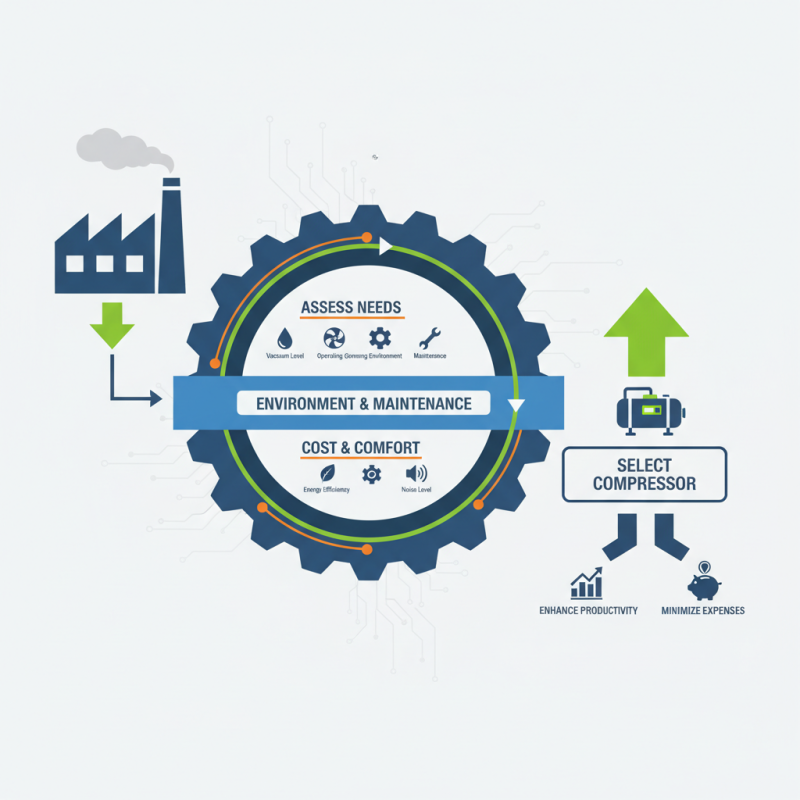

When evaluating potential vacuum compressors, one must consider factors such as the required vacuum level, flow rate, operating environment, and maintenance needs. Additionally, energy efficiency and noise levels can also influence the long-term operational costs and workplace comfort. By comprehensively assessing these aspects, businesses can ensure that their chosen vacuum compressor aligns perfectly with their operational goals, thereby enhancing productivity while minimizing unplanned expenses. This guide aims to provide a foundational understanding of how to navigate the complexities of selecting the most suitable vacuum compressor for your industrial applications.

Understanding Vacuum Compressors and Their Applications in Industry

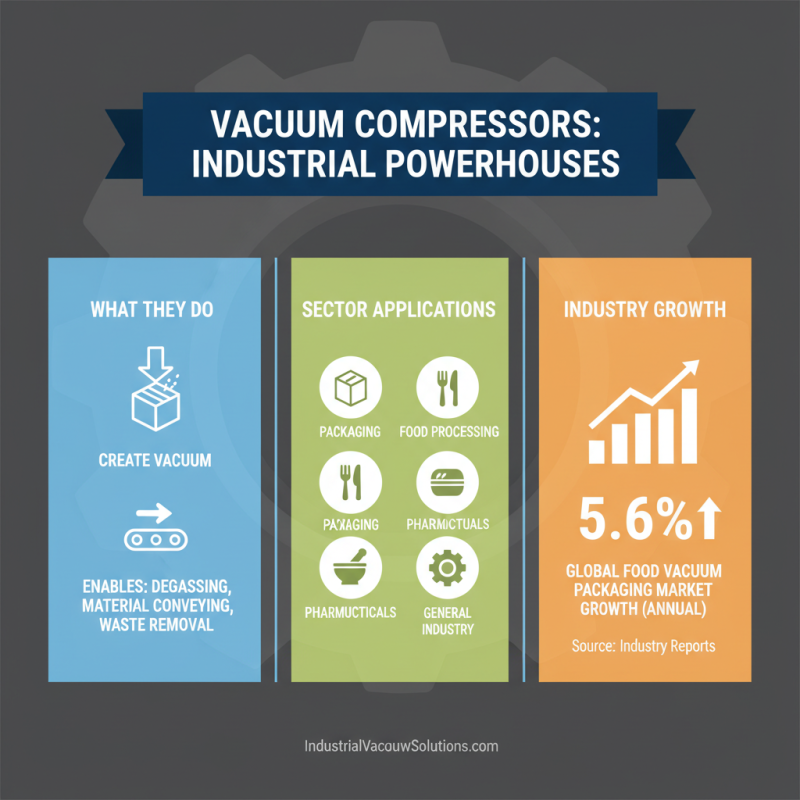

Vacuum compressors play a crucial role in various industrial applications, from packaging to food processing and pharmaceuticals. These machines are designed to create a vacuum that enables processes such as degassing, material conveying, and waste removal. Understanding the unique requirements of your industry is essential for selecting the right vacuum compressor. For instance, the demand for vacuum packaging in the global food industry is projected to grow by 5.6% annually, indicating a significant need for reliable vacuum solutions.

When considering a vacuum compressor, you should evaluate several factors, including the level of vacuum required, flow rate, and energy efficiency. According to industry reports, energy costs can comprise up to 30% of a manufacturing plant's operational expenses, making energy-efficient models a smart choice. Additionally, different industries may have varying certifications and compliance standards; ensuring your vacuum compressor meets these standards is vital for smooth operations.

Tips: Always assess the compatibility of the compressor with the materials it will handle, as chemical reactions can occur if incompatible materials are used. It's also beneficial to consult with experts in the field to tailor your selection to the specific needs and conditions of your application. Regular maintenance and monitoring of your vacuum system can significantly extend its lifespan and maintain optimal performance in demanding industrial environments.

Key Factors to Consider When Selecting a Vacuum Compressor

When selecting a vacuum compressor for industrial applications, it is crucial to consider several key factors to ensure optimal performance and efficiency. One primary factor is the required operating pressure range. According to the Compressed Air and Gas Institute (CAGI), varying industries operate at different pressures; for instance, food processing may require lower pressures for product safety, while pharmaceuticals might necessitate higher, more precise pressures. Understanding the specific pressure requirements of your application will guide you in choosing a compressor that can meet those needs effectively.

Another factor is the compressor's capacity and flow rate, which should align with the operational demands of your facility. The International Journal of Engineering Science estimates that an improperly sized vacuum compressor can result in energy inefficiencies, leading to increased operational costs, which can be as much as 30% higher than efficiently operated systems. It is essential to accurately assess the required flow rates and choose a vacuum compressor that can maintain performance without overworking the motor, thus prolonging the equipment's lifespan and ensuring reliability in production.

Durability and maintenance requirements are also pivotal in the selection process. A report from the Industrial Vacuum Association highlights that less frequent maintenance schedules can significantly reduce downtime and overall costs. Opting for vacuum compressors with robust materials and technology that allow for extended periods between service can be beneficial. This not only minimizes potential disruptions in production but also enhances the overall cost-effectiveness of the vacuum system.

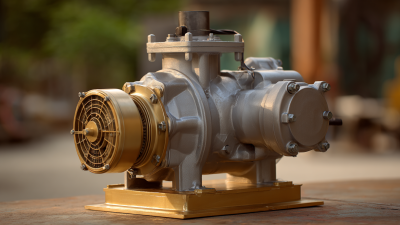

Types of Vacuum Compressors and Their Operational Mechanisms

When selecting the right vacuum compressor for industrial applications, it's crucial to understand the various types available and their operational mechanisms. Common types include positive displacement compressors, dynamic compressors, and liquid ring compressors. Positive displacement compressors, such as rotary vane and screw compressors, operate by trapping air and expelling it to create a vacuum. On the other hand, dynamic compressors utilize high-speed rotating blades to impart kinetic energy to the air, resulting in a continuous flow. According to a report by the International Vacuum Technology Association, the demand for vacuum compressors in industrial applications is projected to grow by 6% annually, indicating a robust market trend towards these technologies.

Understanding the operational mechanisms allows for more informed decisions based on specific industrial requirements. For example, liquid ring compressors are particularly effective in handling moist and corrosive gases, making them suitable for chemical processing industries. In contrast, oil-sealed rotary screw compressors provide a higher efficiency rate for applications requiring a stable vacuum. As you assess your options, it's essential to consider the operating environment and the type of materials being processed.

Tips for selecting the right vacuum compressor include evaluating the required vacuum level, flow rate, and process conditions. Regularly maintaining your equipment is also critical; a well-maintained vacuum compressor can significantly reduce operational costs. Additionally, consult with industry professionals to ensure compliance with safety and environmental regulations, enhancing both productivity and sustainability in your operations.

Assessing Efficiency and Performance Metrics for Industrial Compressors

When selecting a vacuum compressor for industrial applications, assessing efficiency and performance metrics is critical. Efficiency ratings, including specific energy consumption (SEC) and volumetric efficiency, provide insights into how well a compressor converts input power into useful energy while minimizing waste. According to the U.S. Department of Energy, improving the efficiency of industrial air compressors can result in energy savings of up to 30% annually, reflecting significant cost reductions and enhanced sustainability. Understanding these metrics allows businesses to make informed decisions, ensuring that they select models that not only meet their operational demands but also align with their energy conservation goals.

Performance metrics, such as reliability, maintenance frequency, and output pressure consistency, further influence the selection process. A study by the Compressed Air and Gas Institute (CAGI) suggests that maintaining a consistent output pressure is essential for optimizing process efficiency and reducing downtime. Additionally, an effective maintenance plan based on the manufacturer's performance data can extend the life of the compressor and reduce lifecycle costs. By considering these efficiency and performance metrics, businesses can strategically invest in vacuum compressors that enhance operational productivity while driving down overhead costs.

Maintenance and Support Considerations for Long-term Use of Compressors

When selecting a vacuum compressor for industrial applications, maintenance and support considerations are vital for ensuring long-term operational efficiency. Regular maintenance schedules should be established to monitor the compressor's performance and address any potential issues before they escalate. This includes routine checks of essential components such as filters, belts, and oil levels, as well as periodic inspections of the overall system. A well-maintained compressor not only operates more efficiently but also extends its lifespan, reducing the total cost of ownership.

Support considerations also play a crucial role in the longevity of vacuum compressors. Choosing a supplier that offers robust technical support and access to spare parts can greatly reduce downtime in case of equipment failure. It's important to assess the availability of knowledgeable technicians who can provide timely assistance and repairs. Additionally, investing in training for maintenance staff ensures that they are equipped with the skills to handle routine upkeep and troubleshoot problems as they arise, further enhancing the reliability and productivity of the compressor in industrial operations.

How to Choose the Right Vacuum Compressor for Your Industrial Needs - Maintenance and Support Considerations for Long-term Use of Compressors

| Dimension | Description | Importance | Maintenance Tips |

|---|---|---|---|

| Capacity | The volume of gas that the compressor can handle | Crucial for meeting operational demands | Regularly check load requirements and adjust settings |

| Pressure Rating | The maximum pressure the compressor can sustain | Essential for preventing equipment failure | Monitor system pressure and perform regular safety checks |

| Energy Efficiency | How much energy is consumed for operation | Directly impacts operational costs | Calibrate for optimal performance to reduce energy usage |

| Noise Level | The sound produced during operation | Affects workplace comfort and compliance | Consider soundproofing and regular maintenance to minimize noise |

| Durability | Lifespan and robustness of the compressor | Critical for long-term investments | Implement consistent maintenance schedules and inspections |

Related Posts

-

Unlocking Efficiency: The Science Behind Dry Rotary Vane Vacuum Pumps and Their Industry Applications

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

Top 10 Blower Pumps for Efficient Air Movement and Optimal Performance

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications