2025 How to Choose the Right Pump Manufacturer for Your Business Needs

Choosing the right pump manufacturer for your business needs is a critical decision that can significantly impact your operational efficiency and overall success. According to John Smith, a recognized expert in the pump industry, "Selecting a reliable pump manufacturer not only ensures quality and durability but also enhances the long-term performance of your systems." In an increasingly competitive market, understanding the intricacies of pump manufacturing can make a difference between success and failure for many businesses.

The importance of aligning your specific requirements with the capabilities of a pump manufacturer cannot be overstated. Factors such as the range of applications, technological innovations, and after-sales support play crucial roles in the selection process. With the right guidance and knowledge, you can navigate through options available in the marketplace, ensuring that your choice of pump manufacturer is not just a functional fit but also a strategic partnership that propels your business forward.

In this article, we will delve into essential criteria that should influence your decision-making process when selecting a pump manufacturer, providing insights that will help optimize your investment and operational efficacy.

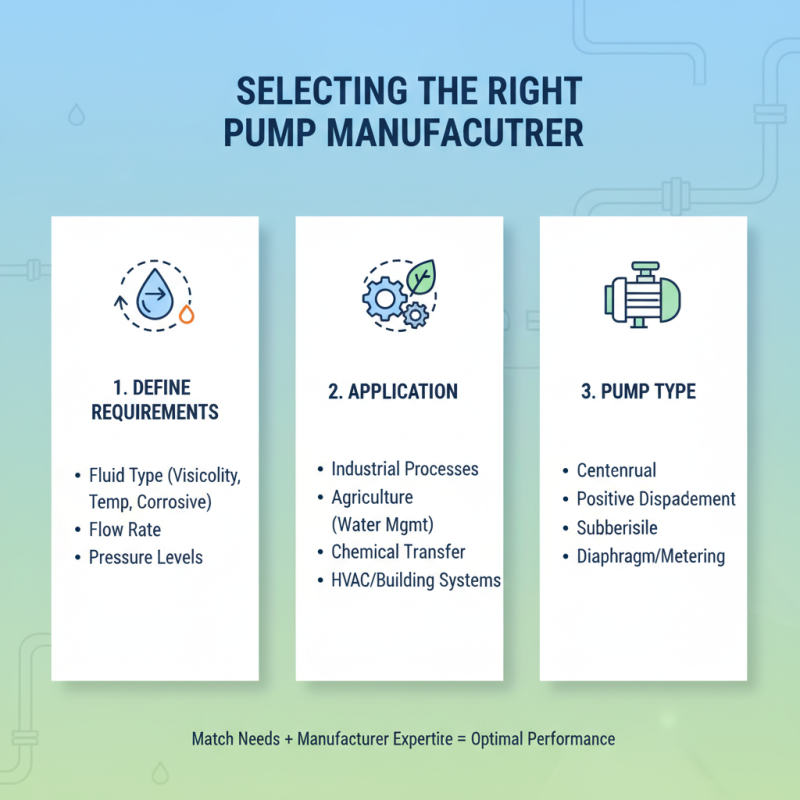

Understanding Your Business's Pump Requirements and Applications

When selecting the right pump manufacturer for your business, understanding your specific pump requirements and applications is crucial. Each industry employs pumps differently, whether for transporting liquids, managing water in agricultural settings, or facilitating chemical processes in manufacturing. Assessing the nature of the fluid that will be pumped, including its viscosity, temperature, and corrosiveness, is essential. Additionally, evaluating the required flow rates and pressure levels can help pinpoint the most suitable pump type, whether it be centrifugal, positive displacement, or submersible.

Furthermore, considering the operational environment is vital in this selection process. Factors such as the installation space, accessibility for maintenance, and potential exposure to harsh conditions will influence your decision. A thorough analysis of your business's intended applications can guide you in prioritizing attributes such as energy efficiency, reliability, and ease of integration with existing systems. This tailored approach not only enhances operational efficiency but also ensures that the selected pump manufacturer aligns with your long-term business goals and sustainability initiatives.

Evaluating Pump Types and Their Suitability for Specific Industries

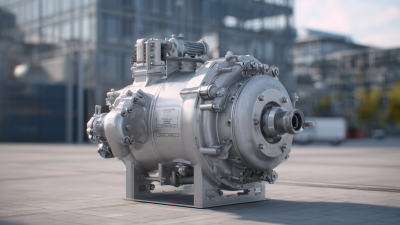

When evaluating pump types for specific industries, it's essential to understand the operational requirements and performance criteria unique to each sector. For instance, in the chemical industry, pumps must not only handle corrosive substances but also provide precise flow rates and consistent pressure to ensure safe and efficient processes.

In contrast, the food and beverage industry demands pumps that adhere to strict hygiene standards while effectively managing varying viscosity levels in different products. Therefore, selecting a pump that meets these criteria is paramount for maintaining production quality and compliance with industry regulations.

Another vital aspect to consider is the energy efficiency and maintenance needs of the pump. Industries such as water treatment and construction often operate under stringent budget constraints, making energy-efficient pumps a practical choice. These pumps can lead to significant cost reductions over time, especially in continuous operation scenarios. Additionally, understanding the frequency and complexity of maintenance required for different pump types can influence the choice, as simpler designs may be preferable in sectors where downtime must be minimized. By aligning pump characteristics with industry-specific demands, businesses can enhance productivity and ensure long-term operational effectiveness.

Assessing Manufacturer Certifications and Compliance Standards

When choosing the right pump manufacturer for your business, it is crucial to assess their certifications and compliance standards. Manufacturers that adhere to industry standards demonstrate a commitment to quality and safety, which can significantly impact your operations. Look for certifications such as ISO 9001, which indicates a well-established quality management system, and other relevant industry-specific certifications. This not only assures you of the manufacturer's credibility but also provides peace of mind regarding the reliability of their products.

Tips: Always request documentation for the certifications claimed by the manufacturer. This ensures that you are not only relying on verbal assurances but have tangible proof of compliance with recognized standards. Additionally, consider a manufacturer's history of past compliance; a track record of meeting or exceeding standards can be a strong indicator of future performance.

Furthermore, it’s essential to evaluate how proactive a manufacturer is in maintaining compliance with evolving regulations. This includes keeping up with safety protocols, environmental standards, and technological advancements. A manufacturer that regularly updates their certifications is typically more invested in quality improvement and customer satisfaction.

Tips: Engage in discussions with manufacturers about their approach to compliance and their processes for staying updated. This insight can help you gauge their overall commitment to quality and service, which can be pivotal in making the right choice for your business.

2025 Pump Manufacturer Certifications and Compliance Standards

This chart illustrates the various certifications and compliance standards that impact the selection of pump manufacturers, highlighting the percentage of companies that meet each standard.

Analyzing Manufacturer Reputation and Customer Reviews in the Market

When selecting the right pump manufacturer for your business needs, analyzing the manufacturer’s reputation is crucial. A manufacturer’s reputation often reflects the quality of their products and their commitment to customer satisfaction. Start by researching the company’s history in the industry. Look for manufacturers with a proven track record of success and longevity, as this can indicate stability and reliability. Moreover, engaging with industry forums or professional networks can provide insights into which manufacturers are regarded favorably among peers.

Customer reviews serve as a vital resource for assessing manufacturer reliability. Take the time to read reviews across multiple platforms, paying attention to patterns in customer feedback. Positive reviews often highlight aspects like product durability and the manufacturer’s responsiveness to inquiries and issues. Conversely, negative reviews can uncover potential pitfalls, such as poor customer service or recurring product defects. By candidly comparing this feedback, businesses can make informed decisions that align with their operational needs and ensure they partner with a manufacturer committed to quality and service excellence.

Comparing Costs and Quality: Finding Value in Pump Solutions

When selecting a pump manufacturer, cost and quality are paramount considerations. It's essential to evaluate not just the upfront costs of the pumps but also the long-term value they bring to your operations. This can mean assessing maintenance requirements, durability, and energy efficiency. A lower initial price may be tempting, but choosing a pump that requires frequent repairs or consumes excessive energy can lead to higher expenses over time. Conducting a total cost of ownership analysis will help in understanding the full financial implications of your purchasing decision.

In addition to cost, the quality of the pump is equally crucial. High-quality pumps are typically constructed with superior materials and undergo rigorous testing to ensure reliability and performance. When researching manufacturers, look for those that have a proven track record and positive customer testimonials. Establishing a relationship with a manufacturer who prioritizes quality can result in better support, customized solutions, and innovations tailored to your business needs. Ultimately, a careful balance of cost and quality will lead you to find the right pump solutions that not only meet your operational demands but also deliver value over the years.

Related Posts

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

Understanding Regenerative Blowers: Types, Applications, and Benefits

-

7 Best Air Tech Innovations Transforming Your Home Experience

-

Top 10 Blower and Vacuum Models of 2023: Efficiency, Power, and User Ratings Reviewed

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data

-

How to Choose the Right Suction Pump for Your Specific Needs