Why Choose a Blower Pump for Your Next Project and How It Benefits You

In the realm of industrial applications, the choice of pumps can significantly impact the efficiency and effectiveness of operations. Among the various types available, blower pumps have emerged as a preferred solution for many projects, thanks to their unique capabilities. According to Dr. Emily Johnson, a leading expert in fluid dynamics, "Blower pumps are not just about moving air; they represent a versatile tool that can enhance project outcomes with improved efficiency and reliability." This insight underscores the growing recognition of blower pumps as a vital technology in industries ranging from manufacturing to environmental management.

The benefits of incorporating blower pumps into your next project are manifold. They not only provide a steady flow of air at varying pressures but also contribute to reduced energy consumption and lower operational costs. By understanding the advantages of blower pumps, businesses can make informed decisions that lead to enhanced productivity and resource management. As we delve deeper into the specifics of blower pumps, it becomes evident how these innovative devices can serve as a game changer in achieving project goals and advancing operational excellence.

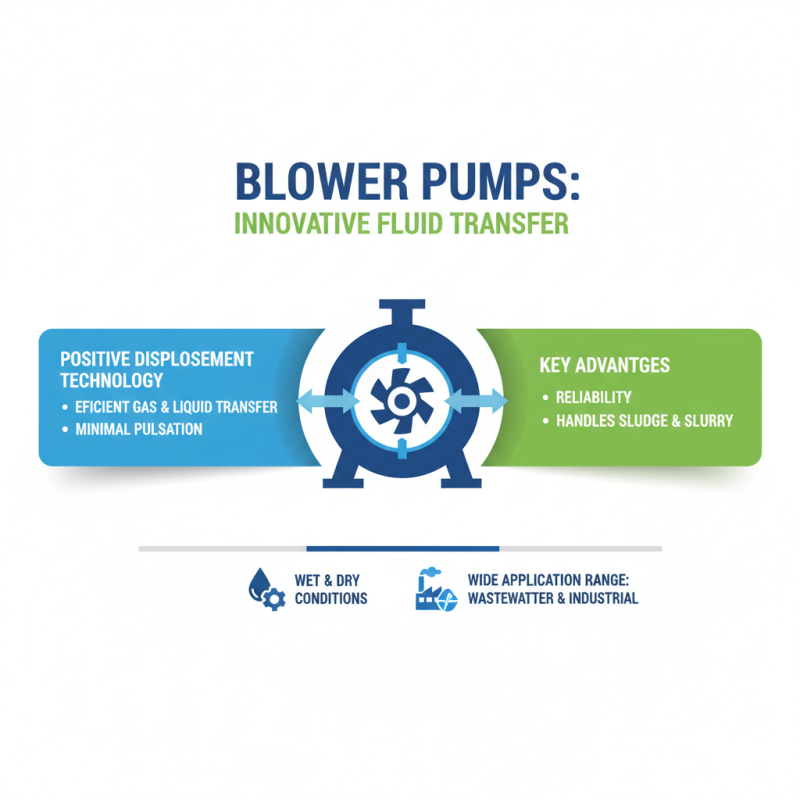

Understanding Blower Pumps: An Overview of Their Functionality

Blower pumps are innovative devices that use positive displacement technology to efficiently transfer gases and liquids. Unlike traditional pumps, blower pumps utilize an impeller that creates a pressure differential, allowing them to move fluid with minimal pulsation. This mechanism not only enhances their reliability but also makes them particularly suitable for handling challenging materials such as sludge and slurry. The ability to operate in both wet and dry conditions expands their application range, from wastewater treatment facilities to industrial processes.

The versatility of blower pumps lies in their functionality, which includes the capability to achieve high flow rates at relatively low energy consumption. By utilizing air or gas as the driving medium, these pumps can maintain consistent performance while reducing the ecological footprint of a project. Additionally, their design typically allows for easy maintenance and adaptability to various operating conditions. This flexibility makes blower pumps an ideal choice for businesses looking to optimize productivity and minimize downtime across various applications.

The Advantages of Using Blower Pumps in Various Applications

Blower pumps have gained popularity across various industries due to their unique advantages. One of the primary benefits of using blower pumps is their ability to handle large volumes of air and materials simultaneously. This feature is particularly useful in applications such as wastewater treatment and material conveying, where efficient transfer is critical. With the capability to maintain consistent pressure and flow rates, blower pumps enhance process efficiency and reduce downtime, leading to increased productivity.

Moreover, blower pumps are known for their durability and low maintenance requirements. Their simple design typically translates to fewer moving parts compared to other pump types, which means there are fewer points of failure. This reliability makes them ideal for demanding environments where pumps are subjected to continuous operation. Additionally, blower pumps are energy-efficient, often consuming less power than alternative systems, resulting in lower operational costs. These attributes not only make them a smart investment but also contribute to sustainability efforts in various sectors.

Key Factors to Consider When Choosing a Blower Pump for Your Project

When selecting a blower pump for your next project, several key factors should guide your decision to ensure efficiency and effectiveness. First and foremost, consider the flow rate and pressure requirements specific to your application. According to industry reports, a well-matched blower pump can improve operational efficiency by up to 20%, thus optimizing your process. Ensuring that the pump offers a flow rate that meets your system's demands can prevent costly downtime and maximize productivity.

Another crucial aspect is the material composition of the blower pump. Depending on the nature of the materials being handled—whether abrasive, corrosive, or simply demanding in terms of pressure—selecting the appropriate materials is vital for longevity and durability. Studies indicate that pumps constructed from high-quality alloys can extend service life by 30%, significantly reducing replacement frequency and maintenance costs.

Additionally, energy efficiency ratings should not be overlooked. A blower pump that operates at higher efficiency will not only lower operational costs but also align with sustainability goals increasingly prioritized in modern industrial practices. Thus, ensuring that your selected pump meets established energy performance benchmarks can lead to significant savings in both energy consumption and environmental impact.

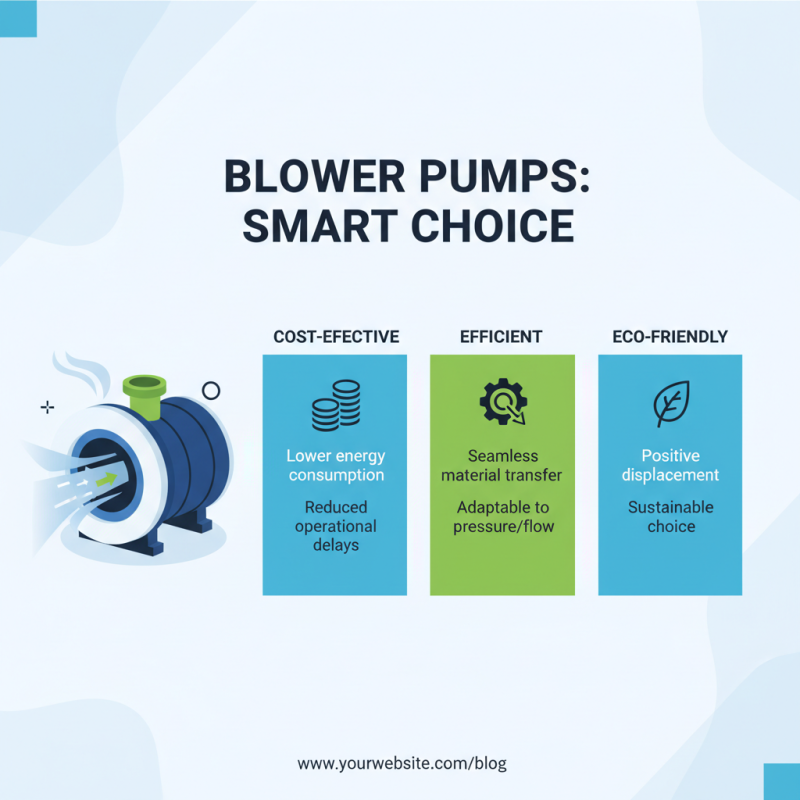

Cost-Effectiveness and Efficiency of Blower Pumps Compared to Alternatives

When considering a pumping solution for your next project, blower pumps stand out as a cost-effective and efficient choice compared to traditional alternatives. The design of blower pumps allows for a seamless transfer of materials, resulting in fewer operational delays. These pumps utilize a positive displacement mechanism, which means they can handle varying pressures and flow rates without compromising performance. This adaptability not only enhances efficiency but also leads to lower energy consumption over time, making them an environmentally friendly option.

Moreover, the initial investment in blower pumps often translates into long-term savings. With fewer moving parts compared to centrifugal or diaphragm pumps, blower pumps have reduced maintenance requirements, which can significantly cut down on operational costs. Their robust construction also ensures durability, minimizing the need for parts replacement and repairs. In industries where downtime equates to lost revenue, the reliability of blower pumps can provide a competitive edge, ensuring consistent and effective performance throughout the project lifecycle. Overall, the cost-effectiveness and efficiency of blower pumps make them a superior choice for various applications.

Maintenance and Longevity: Ensuring Optimal Performance of Blower Pumps

When incorporating blower pumps into your project, understanding the maintenance and longevity of these systems is crucial for ensuring optimal performance. Blower pumps, known for their ability to efficiently transport air and other gases, require regular maintenance to function at their best. According to the Pneumatic Conveying Data report from the International Society of Automation, routine inspections and upkeep can increase the lifespan of blower pumps by up to 30%. Regular maintenance not only helps in identifying potential issues before they escalate but also ensures that the system operates at peak efficiency, significantly reducing energy costs.

Additionally, the design of blower pumps allows for greater durability compared to other types of pumps. Expert analyses from the American Society of Mechanical Engineers indicate that proper lubrication and filter checks can enhance blower performance and extend service life. Systems that operate in environments with high dust or particulate matter benefit from frequent cleaning and monitoring, further prolonging the pump’s operational reliability. By committing to a proactive maintenance strategy, companies can significantly mitigate downtime and elevate the overall productivity of their processes, securing a competitive edge in their operations.

Why Choose a Blower Pump for Your Next Project and How It Benefits You - Maintenance and Longevity: Ensuring Optimal Performance of Blower Pumps

| Aspect | Description | Benefits |

|---|---|---|

| Energy Efficiency | Blower pumps use lower energy levels due to their design. | Reduced operating costs and lower carbon footprint. |

| Maintenance Requirements | Blower pumps typically require less maintenance than traditional pumps. | Increased uptime and reduced labor costs. |

| Longevity | Blower pumps are designed for long operational life with durable materials. | Lower replacement costs over time and consistent performance. |

| Performance Consistency | They provide stable airflow which is crucial for many applications. | Improved process reliability and product quality. |

| Noise Levels | Blower pumps operate more quietly compared to other pump types. | More pleasant working environment and compliance with noise regulations. |

Related Posts

-

Top 10 Blower Pumps for Efficient Air Movement and Optimal Performance

-

Exploring the Efficiency of Oil Vacuum Pumps: The Future of Industrial Sustainability

-

What is Air Vacuum? Understanding Its Types and Uses for Your Home

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

-

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

How to Optimize Your Facility's Efficiency with Regenerative Blowers: Insights and Data