What is a Blower and Vacuum and How Do They Work?

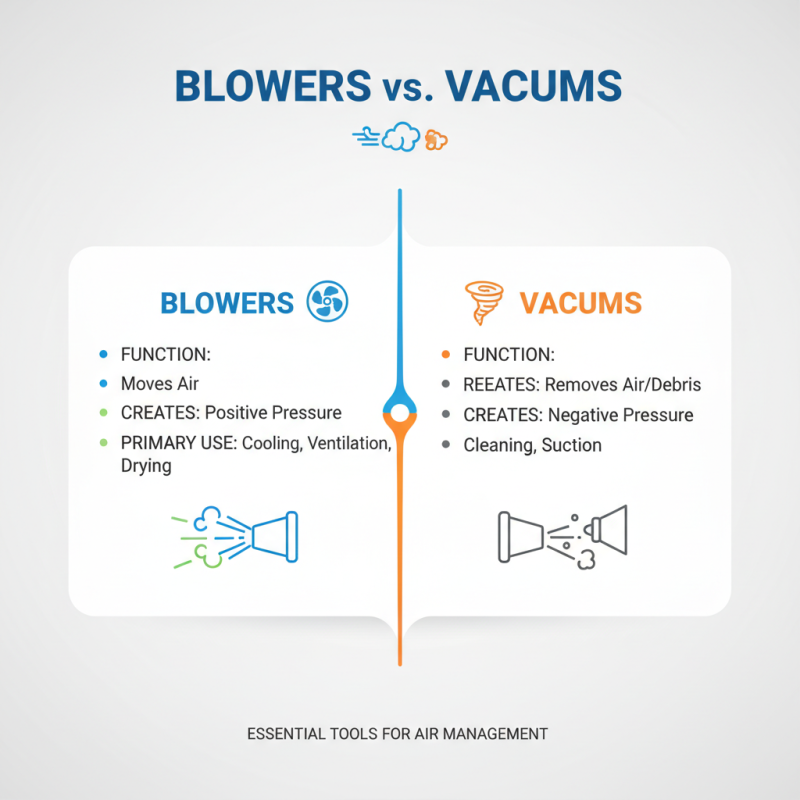

A blower and vacuum are essential tools in various industries. They serve different functions but share a common principle: manipulating air. Blowers move air at high speeds. They can help dry surfaces, clear debris, or cool equipment. Vacuums, on the other hand, create suction. They pick up dirt and dust, keeping spaces clean.

Understanding how these tools work is vital. A blower and vacuum operate based on pressure differences. The blower pushes air out, while the vacuum pulls air in. This process can seem straightforward, yet there are complexities. For example, choosing the right blower and vacuum for specific tasks can be tricky. One must consider factors like size, power, and application. Misjudgments might lead to inefficiency or even damage.

Exploring the functionality of blowers and vacuums reveals their importance. These devices enhance productivity and maintain cleanliness. Yet, the choice of a blower and vacuum requires careful thought. Users must evaluate needs and potential challenges. This reflection can lead to better decision-making and effective use of these powerful tools.

Definition of Blowers and Vacuums

Blowers and vacuums are essential tools in many industries. They serve distinct but critical functions in managing air movement. A blower moves air. It generates a flow of air for cooling or ventilation. In contrast, a vacuum removes air or dust from a space. It creates a negative pressure that sucks in dirt or debris.

The design of blowers and vacuums is simple yet effective. A blower typically includes a fan or turbine that pushes air outward. Its efficiency often depends on blade design and motor power. A vacuum, however, employs a motorized fan to create suction. The collection of debris happens through filters or bags. Misusing these tools can lead to inefficiency. For instance, overloading a vacuum can cause it to lose suction power quickly.

Understanding the applications of these devices is vital. Blow air for cooling electronics or blowing leaves in the yard. Use vacuums for cleaning carpets or industrial floors. However, some people misuse these tools, not realizing their limits. Not all vacuums can handle wet surfaces, and some blowers may not provide sufficient airflow for large areas. Awareness of these details can enhance performance and efficiency.

Types of Blowers and Their Applications

Blowers and vacuums serve vital roles in various industries. Different types of blowers, like centrifugal and positive displacement, are designed for specific tasks. Centrifugal blowers are commonly used in HVAC systems, providing efficient airflow. According to industry reports, they can achieve efficiencies exceeding 80%. This makes them suitable for both residential and industrial applications.

Positive displacement blowers are known for generating high-pressure airflow. They find their application in wastewater treatment plants. Their ability to move air at consistent pressure is essential for optimal operation. However, they can also be more complex to maintain, which may cause frustration for some operators.

Tip: Regular maintenance checks are crucial for sustaining performance. Schedule inspections every six months to catch potential issues early. This practice can save costs and improve efficiency.

Another type, the regenerative blower, is often used in aquaculture. Its ability to deliver large volumes of air makes it perfect for oxygenation. Despite its advantages, improper sizing can lead to inefficiencies and increased operational costs.

Tip: Always calculate the required air flow before selecting a blower. Mismatches can lead to overworking the unit, which shortens its lifespan. Understanding your needs is essential for long-term efficiency.

Types of Blowers and Vacuums and Their Applications

Types of Vacuums and Their Uses

When it comes to vacuums, there are various types designed for specific tasks. Canister vacuums are versatile. They work well on carpets and hard surfaces. They often have a long hose, making it easier to clean tight spaces. Upright vacuums are great for large areas. They can pick up debris easily from carpets, but may struggle on stairs.

Handheld vacuums are compact. They are perfect for quick clean-ups. You can use them for small messes like crumbs or dust. However, they usually have a shorter battery life. Robot vacuums operate autonomously. They can save time but may miss spots. Their ability to navigate may not be perfect.

Tips: Regularly check your vacuum filters. A clean filter ensures maximum suction. Also, empty the dust bin often. A full dust bin can decrease performance. Don't forget to clean the brush rolls too; hair and debris can build up and affect cleaning.

Working Principles of Blowers

Blowers are essential devices used for moving air or gas. Their working principle relies on mechanical components that create airflow. A blower typically contains a motor spinning blades, which push air or gas out. This process generates pressure, allowing the transfer of air over distances. The blades’ design affects the flow rate and pressure generated.

In contrast, vacuum systems work by removing air from a confined space. They operate on a different principle, where air is drawn in, creating a lower pressure area. This pressure difference allows for the efficient movement of materials, like dust or debris. The key components include a motor and an impeller that helps in creating suction. The effectiveness of vacuums relies heavily on proper sealing and efficiency of components.

There are challenges in both systems. For blowers, noise can be a concern, making them less suitable for quiet environments. Vacuums may struggle with maintaining suction if filters clog or seals fail. Observing these systems closely can provide insights for better design and efficiency. Identifying and addressing limitations helps in creating more effective air movement solutions.

Working Principles of Vacuums

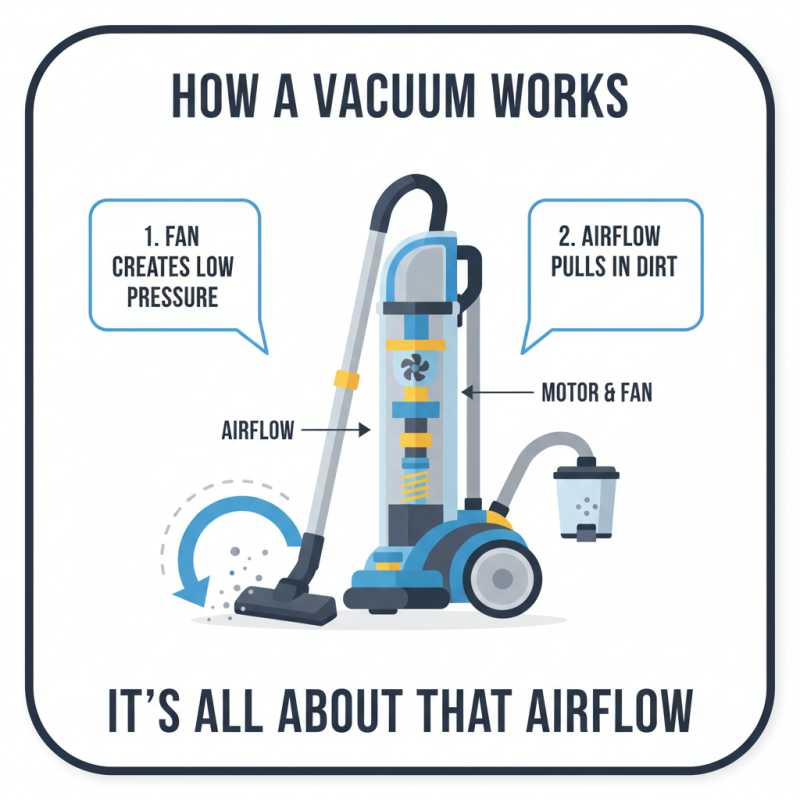

Understanding the working principles of vacuums can simplify our daily lives. A vacuum operates by creating a low-pressure area, allowing air and particulates to be drawn in. When the motor runs, it powers a fan, which generates airflow. This airflow creates a pressure difference that pulls in dirt and debris. It's all about that airflow.

Once inside, the particles pass through various filters. These filters trap the dirt, ensuring cleaner air is expelled back into the environment. It’s fascinating how a simple mechanical process can effectively remove unwanted materials. However, maintaining the filters is crucial. A clogged filter can diminish suction power. Frequent cleaning is necessary for optimal performance.

Vacuums are not perfect. They struggle with larger debris or liquids, which can cause malfunctions. Also, at times, they create a lot of noise and require electrical outlets. These are important factors to consider for efficient use. Understanding these principles deepens our appreciation of how vacuums function in our homes.

Conclusion

Blowers and vacuums are essential tools used in various industries and applications. A blower is designed to generate a high-velocity airstream to move or ventilate air, while a vacuum operates by creating a low-pressure area, effectively sucking up dirt and debris. There are several types of blowers, including centrifugal and positive displacement blowers, each suitable for specific tasks such as cooling, aeration, and dust collection. Similarly, vacuums come in various forms, including standard household models and industrial-grade units, used for cleaning and material handling.

The working principles of blowers involve forcing air through a defined path, which enhances airflow, whereas vacuums rely on the creation of suction to draw air along with particles into the device. Understanding the key differences between blowers and vacuums is crucial for selecting the right tool for a given application. Overall, the proper use of a blower and vacuum can greatly improve efficiency and productivity across different settings.

Related Posts

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

Top 10 Blower and Vacuum Models of 2023: Efficiency, Power, and User Ratings Reviewed

-

Top Benefits of Regenerative Blowers: Applications and Efficiency Explained

-

Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

-

Top Factors to Consider When Choosing a High Vacuum Pump for Your Needs

-

2026 How to Choose the Right Vacuum Blower Pump for Your Needs?