What is a Blower Manufacturer? Understanding Their Role and Importance in Industry

In today's industrial landscape, the role of a blower manufacturer is pivotal in ensuring efficiency and reliability across various sectors. Blower manufacturers design and produce machines that facilitate air flow, critical for applications ranging from HVAC systems to industrial processes. According to a recent industry report by Global Market Insights, the blower market is projected to reach USD 13 billion by 2027, highlighting the growing demand for these essential machines.

Expert insights shed further light on the significance of this industry. John Smith, a renowned specialist in fluid dynamics, emphasizes, "Blower manufacturers are foundational to the infrastructure that supports modern industry. Their products not only enhance operational efficiency but also contribute to energy savings and environmental sustainability." Such statements underscore the integral role that blower manufacturers play in both economic and ecological contexts.

As industries evolve and seek innovative solutions to meet new challenges, the emphasis on high-quality blower manufacturing continues to rise, making it essential to understand their contributions and complexities further. Through ongoing advancements, these manufacturers remain at the forefront of technological progress, shaping the future of various industries worldwide.

What Is a Blower Manufacturer? An Overview of the Industry

Blower manufacturers play a crucial role in various industries by providing essential equipment for ventilation, cooling, and material handling. These specialized manufacturers design and produce blowers that generate airflow through mechanical means. The industry encompasses a wide range of applications, from supporting HVAC systems in commercial buildings to facilitating processes in the food, pharmaceutical, and environmental sectors.

When considering a blower manufacturer, it's essential to evaluate their expertise and the variety of blowers they offer. Different industries may require specific types of blowers, such as centrifugal or positive displacement blowers, catering to various pressure and flow needs. Understanding the specifications and capabilities of each type helps businesses make informed decisions about the equipment best suited for their operations.

Tips: Always inquire about customization options; many blower manufacturers can tailor their products to meet unique operational requirements. Additionally, consider manufacturers that provide robust after-sales support, as maintenance and servicing can significantly extend the life of the blowers and ensure optimal performance in demanding environments.

What is a Blower Manufacturer? Understanding Their Role and Importance in Industry

| Dimension | Description | Importance |

|---|---|---|

| Types of Blowers | Positive Displacement, Centrifugal, Regenerative | Different applications require specific types for efficiency. |

| Applications | HVAC systems, Wastewater Treatment, Industrial Processes | Essential for operational efficiency and environmental compliance. |

| Materials Used | Stainless Steel, Cast Iron, Plastic | Material selection affects durability and performance. |

| Energy Efficiency | Variable Speed Drives, High-Efficiency Motors | Improves sustainability and reduces operational costs. |

| Market Trends | Automation, Smart Technology Integration | Staying competitive and addressing changing consumer needs. |

Key Types of Blowers and Their Applications in Various Sectors

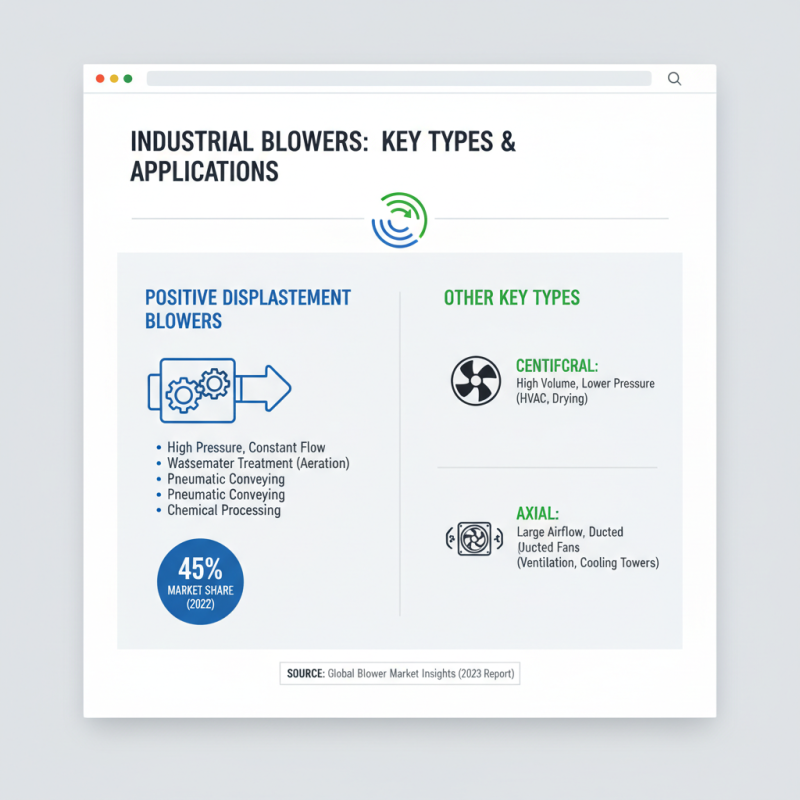

Blowers play a crucial role in various industries by efficiently moving air and gases for numerous applications. There are several key types of blowers, each designed for specific industrial needs. Positive displacement blowers, for example, are widely used in wastewater treatment plants to aerate sludge and ensure the proper functioning of biological processes. According to a report by the Global Blower Market Insights, the positive displacement segment accounted for approximately 45% of the total market share in 2022, underscoring its importance in sectors reliant on consistent airflow.

Another prominent type is centrifugal blowers, which are favored in manufacturing and environmental control applications. They work through the rotation of blades that impart kinetic energy to the air, making them highly effective for ventilation in industrial settings. The demand for centrifugal blowers has been growing, with industry forecasts predicting a compound annual growth rate (CAGR) of 3.5% from 2023 to 2028. This growth can be attributed to the increasing need for efficient air management systems in industries such as automotive and food processing, where air quality directly affects product safety and operational efficiency.

Moreover, in the power generation sector, blowers are essential for maintaining combustion airflow and enhancing the performance of gas turbines. The integration of advanced blower systems can lead to significant energy savings and reduced emissions, aligning with global sustainability goals. As industries continue to evolve, the importance of blowers in optimizing operational efficiency and environmental impact cannot be overstated, highlighting their vital role across multiple sectors.

The Manufacturing Process: From Design to Production of Blowers

The manufacturing process of blowers involves several critical stages, from initial design to production.

Typically, the process begins with detailed engineering specifications that outline the performance requirements, including airflow rates, pressure capabilities, and energy efficiency.

According to industry reports, the global blower market is projected to reach USD 11.76 billion by 2026, highlighting the significant demand for high-quality blower systems in various applications.

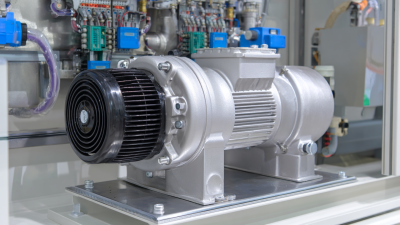

Effective design integrates advanced computational fluid dynamics (CFD) to optimize airflow and minimize energy consumption, while adhering to relevant standards and regulations.

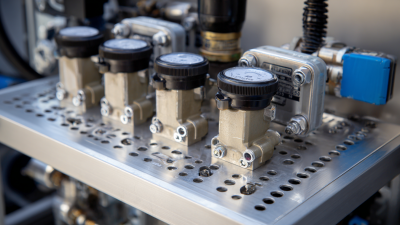

Once the design phase is completed, the production process involves selecting suitable materials, often lightweight and durable alloys or plastics, that can withstand operational conditions.

Advanced manufacturing techniques, such as CNC machining and injection molding, are commonly employed to achieve precise tolerances and enhance performance reliability.

Recent studies indicate that the adoption of Industry 4.0 technologies, including automation and IoT-enabled monitoring, has led to improvements in production efficiency by up to 30%.

This innovation not only reduces lead times but also enables manufacturers to respond more swiftly to market demands, ensuring that blowers meet evolving industry standards.

Market Trends: Growth and Demand for Blower Systems in 2023

The demand for blower systems is witnessing significant growth in 2023, largely driven by the expanding industrial landscape and the growing need for efficient air management solutions. According to industry reports, the global blower market is expected to reach USD 10.5 billion by 2025, with a compound annual growth rate (CAGR) of 7.6%. This surge is fueled by sectors such as manufacturing, wastewater treatment, and HVAC, where blowers play a crucial role in enhancing operational efficiency.

As industries progressively invest in technology for better performance and sustainability, the importance of blower manufacturers cannot be overstated. These manufacturers provide essential equipment that caters to various applications, including pneumatic conveying, chemical processing, and air pollution control. In 2023, innovations in blower technology, such as energy-efficient designs and smart monitoring systems, are becoming critical trends. Companies are increasingly opting for advanced air systems that not only reduce operational costs but also comply with stringent environmental regulations.

Tips: When selecting a blower system, consider the specific requirements of your application, such as air volume and pressure demands. It's also advisable to evaluate the energy efficiency of the system, as this can significantly impact your long-term operational costs. Regular maintenance is essential for optimal performance; therefore, ensure that your equipment is backed by a reliable service provider.

Regulatory Standards and Certifications for Blower Manufacturers

Blower manufacturers play a crucial role in various industries, as they design and produce equipment that is essential for air and gas movement. To ensure safety, efficiency, and reliability, these manufacturers must adhere to regulatory standards and certifications that set the benchmark for product quality. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide guidelines that blower manufacturers must follow. According to a report by MarketsandMarkets, the global blowers market is projected to reach USD 8.6 billion by 2024, reflecting the growing need for compliant and efficient blower systems in sectors like HVAC, wastewater treatment, and industrial applications.

For blower manufacturers, obtaining certifications like ISO 9001, which focuses on quality management systems, is essential. This certification assures customers that the manufacturer adheres to rigorous quality control processes, thereby reducing operational risks. Moreover, compliance with environmental standards, such as the Environmental Protection Agency (EPA) regulations in the U.S., ensures that the blowers not only operate efficiently but also minimize emissions and environmental impact. As the industry moves towards sustainability, manufacturers are increasingly seeking certifications that align with green initiatives, highlighting the importance of Eco-Management and Audit Scheme (EMAS) for those aiming to enhance their environmental performance.

**Tips:** When choosing a blower manufacturer, verify their certifications and adherence to recognized standards. This can significantly impact the reliability and efficiency of your industrial processes. Also, consider engaging with manufacturers who actively pursue sustainability certifications to align with contemporary environmental goals.

Blower Manufacturer Compliance with Regulatory Standards

This chart illustrates the percentage of blower manufacturers that comply with various regulatory standards, including ISO 9001, OSHA, and CE certification. Compliance with these standards is crucial for ensuring safety, quality, and environmental responsibility in the manufacturing process.

Related Posts

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

-

10 Custom Engineering Tips to Boost Your Project Efficiency by 40% in 2023

-

Top 10 Blower and Vacuum Models of 2023: Efficiency, Power, and User Ratings Reviewed

-

How to Choose the Right Suction Pump for Your Specific Needs

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs

-

7 Best Air Tech Innovations Transforming Your Home Experience