Top 5 Best Liquid Ring Vacuum Pumps You Should Consider?

In the industrial landscape, liquid ring vacuum pumps play a crucial role in various applications. These pumps offer unique advantages like lower maintenance and operational costs. A recent industry report indicates that the demand for liquid ring vacuum pumps is expected to grow significantly, potentially reaching a market value of over $1.5 billion by 2025.

Many businesses are still unsure about the best liquid ring vacuum pump for their needs. The effectiveness of these pumps can vary based on application type and environment. For instance, in processes like distillation and evaporation, a well-chosen pump greatly enhances efficiency. However, several companies overlook these details. This can lead to suboptimal performance and increased energy consumption.

Understanding the specifications of different pumps is essential. Each application might require a different design or material. The right liquid ring vacuum pump can provide significant energy savings. Yet, selecting the wrong model may not always be easy. Overlooking these aspects can lead to operational challenges, which companies should critically evaluate. Making informed decisions is more important than ever.

Overview of Liquid Ring Vacuum Pumps and Their Applications

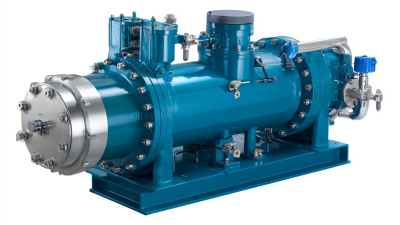

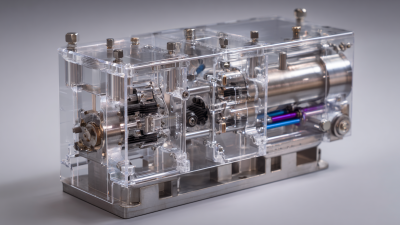

Liquid ring vacuum pumps are essential in various industrial applications. They operate by creating a vacuum through a rotating liquid ring. This unique design allows for effective gas removal while maintaining a simple mechanical setup. The liquid, often water or a suitable oil, forms a closed loop and captures gas molecules efficiently.

These pumps excel in handling wet, corrosive, or hazardous gases. A notable advantage is their ability to maintain a vacuum even with fluctuating gas volumes. However, they can have issues with liquid carryover. It's also crucial to manage the temperature of the working fluid to optimize performance.

In wastewater treatment, these pumps play a significant role. They help in the degassing process, ensuring efficient operation. Moreover, they are valuable in food processing and pharmaceutical industries. They provide a reliable method for handling vapors without contamination. Yet, end-users must remain vigilant about maintenance to prevent inefficiencies. Selecting the right model is essential for maximizing performance.

Criteria for Selecting the Best Liquid Ring Vacuum Pumps

When selecting a liquid ring vacuum pump, the design of the pump is crucial. Look for pumps with a durable and robust construction. The material affects the pump's efficiency and lifespan. A strong casing can withstand harsh operating conditions.

Next, consider the performance metrics. Check the pumping speed and ultimate vacuum level. Each application has different requirements. You might face difficulties if the pump does not meet your specific needs. Efficiency should also be a priority; consider energy consumption versus performance.

It's important to account for maintenance needs. Some pumps may require more frequent servicing. This can lead to increased costs over time. Reflect on how often you are willing to perform maintenance. Additionally, review noise levels. A quieter pump can improve working conditions. Balancing performance with these practical aspects will help you make a more informed decision.

Top 5 Liquid Ring Vacuum Pumps of 2023: Features and Benefits

When selecting the best liquid ring vacuum pumps, it's essential to understand their unique features and benefits. The global market for liquid ring vacuum pumps is projected to grow at a CAGR of 4.8% from 2021 to 2026, highlighting their increasing popularity. These pumps are reliable and efficiently handle wet or corrosive gases. They are often used in industries like pharmaceuticals and food processing.

One key benefit of liquid ring vacuum pumps is their ability to operate reliably in challenging environments. They can achieve vacuum levels up to 30 inches of mercury. Many models have an integrated water-cooling system, which minimizes thermal issues during operation. However, maintenance can be a concern. Regular upkeep is required to prevent performance declines. The use of contaminated water can also lead to operational inefficiencies.

Energy efficiency is another critical factor. These pumps generally consume less energy than other types, which is a significant advantage in large-scale operations. Yet, their effectiveness can vary based on the specific application. Some users report inconsistent performance when handling varying gas compositions. It’s crucial to match the pump selection with application needs for optimal outcomes. Thus, understanding the operational context is vital for achieving desired results.

Comparative Analysis of Performance and Efficiency

When analyzing liquid ring vacuum pumps, performance and efficiency are critical factors. These pumps typically operate within a pressure range of 1 to 30 Torr. They are known for energy efficiency and lower operational costs. According to industry reports, modern designs have achieved up to 90% overall efficiency. This efficiency is particularly noticeable in applications needing continuous operation.

However, not all liquid ring vacuum pumps perform equally. Variations in rotor design and materials can lead to significant differences in performance. For instance, pumps made with corrosion-resistant materials can maintain efficiency over time, especially in harsh environments. The choice of liquid used for sealing also impacts efficiency. Water is common, but using oils can increase energy consumption, leading to inefficiencies.

Another point to consider is maintenance needs. While these pumps are generally reliable, they can require regular check-ups. Neglecting maintenance can lead to performance drops of 15-20%. Thus, while liquid ring vacuum pumps provide significant advantages, their performance is not a guarantee. Users should consider both immediate needs and long-term operational costs in their analysis.

Top 5 Best Liquid Ring Vacuum Pumps You Should Consider

| Model | Max Vacuum (Torr) | Flow Rate (CFM) | Motor Power (HP) | Efficiency (%) |

|---|---|---|---|---|

| Model A | 25 | 100 | 10 | 85 |

| Model B | 29 | 120 | 15 | 88 |

| Model C | 22 | 95 | 8 | 82 |

| Model D | 30 | 150 | 20 | 90 |

| Model E | 27 | 110 | 12 | 87 |

Maintenance Tips for Prolonging the Life of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps are essential for various industrial applications. Proper maintenance is key to ensuring their longevity. Regular checks can prevent unexpected breakdowns that disrupt operations. A small oversight can lead to significant costs and delays.

One crucial tip is to monitor the pump's fluid levels regularly. Insufficient liquid can cause overheating and damage. Keep the intake and discharge lines clear to avoid blockages. This can improve performance and efficiency. Also, inspect seals and gaskets frequently. Worn components can lead to leaks and inefficiencies.

Another important aspect is to maintain the appropriate operating temperature. Excess heat can be detrimental to the pump's life. Ensure that cooling systems are functioning well. Cleaning dust and debris from the motor and vents can enhance airflow. Don’t forget to listen for unusual sounds during operation. This could indicate a problem that needs immediate attention. Taking these simple steps can keep your liquid ring vacuum pump running smoothly for years.

Related Posts

-

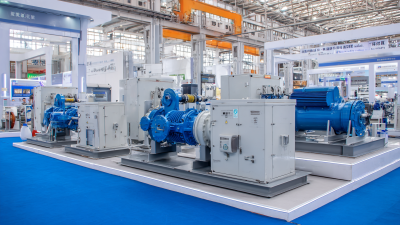

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies