2026 Best Dry Vacuum Pumps for Efficient Industrial Applications?

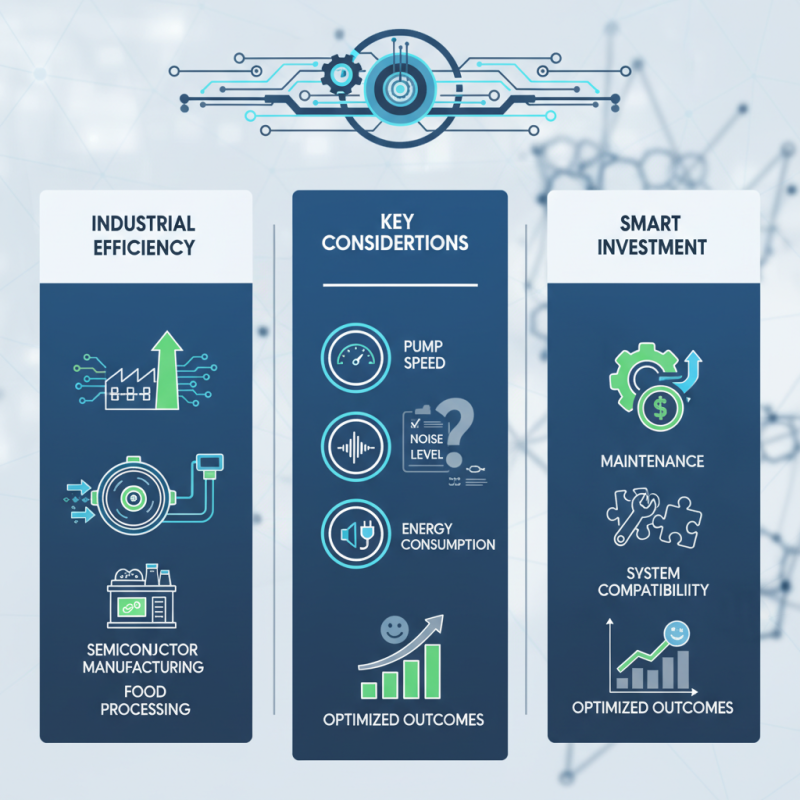

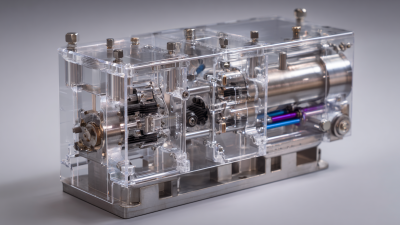

In the industrial world, efficiency is paramount. A dry vacuum pump can significantly enhance operational performance. They are widely used in various applications, from semiconductor manufacturing to food processing. Choosing the right model can be challenging.

The market offers numerous options, each with its own benefits and drawbacks. Features like pump speed, noise level, and energy consumption vary widely. It's crucial to assess these factors to find a suitable pump for specific needs.

Investing in a high-quality dry vacuum pump is a step towards optimizing industrial processes. However, users often encounter challenges during selection. Some may overlook maintenance requirements or compatibility with existing systems. Reflecting on these aspects can lead to better decision-making and improved outcomes.

2026 Trends in Dry Vacuum Pump Technologies for Industrial Use

In 2026, dry vacuum pump technology is evolving rapidly. Industrial applications demand efficiency and reliability. These pumps are crucial for sensitive processes. Industries focus on reducing energy consumption. This trend is reshaping design and functionality.

New innovations aim for lower noise levels and smaller footprints. Manufacturers explore alternative materials for enhanced durability. However, the shift towards eco-friendly models requires careful consideration. Performance vs. sustainability is a constant challenge. There’s always a risk of compromising on power and efficiency for greener solutions.

Monitoring and maintenance will play vital roles in this landscape. Automated systems are becoming more common. Yet, relying solely on technology can lead to unforeseen issues. Regular human oversight remains essential. The balance between innovation and practical application is delicate. Future advancements must prioritize user needs while addressing industrial standards.

Comparative Analysis of Leading Dry Vacuum Pumps in the Market

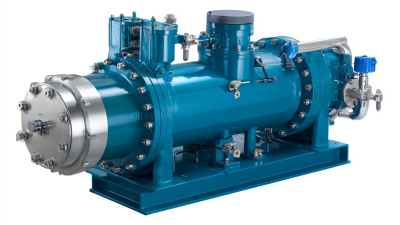

When selecting a dry vacuum pump for industrial applications, performance and efficiency are key. Different models have varying specifications that can impact operations significantly. For instance, some pumps excel in high-temperature environments, while others are designed for large-scale production. Understanding these differences can direct you to the right choice.

Tips: Always consider the pump's maintenance requirements. Some models may need frequent servicing, which can be costly. Look for pumps with longer service intervals to reduce downtime.

Comparative analysis reveals that noise levels are another essential factor. Some vacuum pumps operate quietly, while others generate considerable noise. Investigate noise ratings if working in sound-sensitive environments. It’s worth noting that high capacity does not always equate to efficiency.

Tips: Review energy consumption data. A less powerful pump might save energy while providing adequate performance for your needs.

Finally, consider the material compatibility. Not all pumps handle all substances. This misalignment can lead to breakdowns. Choosing the wrong pump can result in inefficiencies and unexpected costs. Take time to analyze these aspects carefully.

Efficiency Metrics: Evaluating Performance of Industrial Vacuum Pumps

When assessing the performance of industrial vacuum pumps, efficiency metrics are critical. These metrics often include the pump's ultimate vacuum level, pumping speed, and power consumption. According to industry reports, a high-performance dry vacuum pump can achieve ultimate vacuum levels as low as 0.001 mbar. This level is crucial for applications requiring stringent contamination control.

Besides vacuum levels, pumping speed directly impacts operational efficiency. For instance, a pump that provides a high flow rate can evacuate chambers faster, which reduces downtime. Reports indicate that top models can reach flow rates exceeding 200 m³/h. However, balancing speed and energy consumption can be challenging. Some pumps with high flow rates may consume excessive energy, leading to inflated operational costs.

Additionally, noise levels and maintenance requirements also affect overall efficiency. Many industrial settings prefer quieter pumps, ideally under 70 dB. This preference stems from workplace safety and comfort concerns. Regular maintenance is another factor often overlooked. Neglecting simple maintenance tasks can reduce the pump's efficiency, leading to increased costs and downtime. Reflecting on these challenges is essential for selecting the right vacuum pump to meet diverse industrial needs.

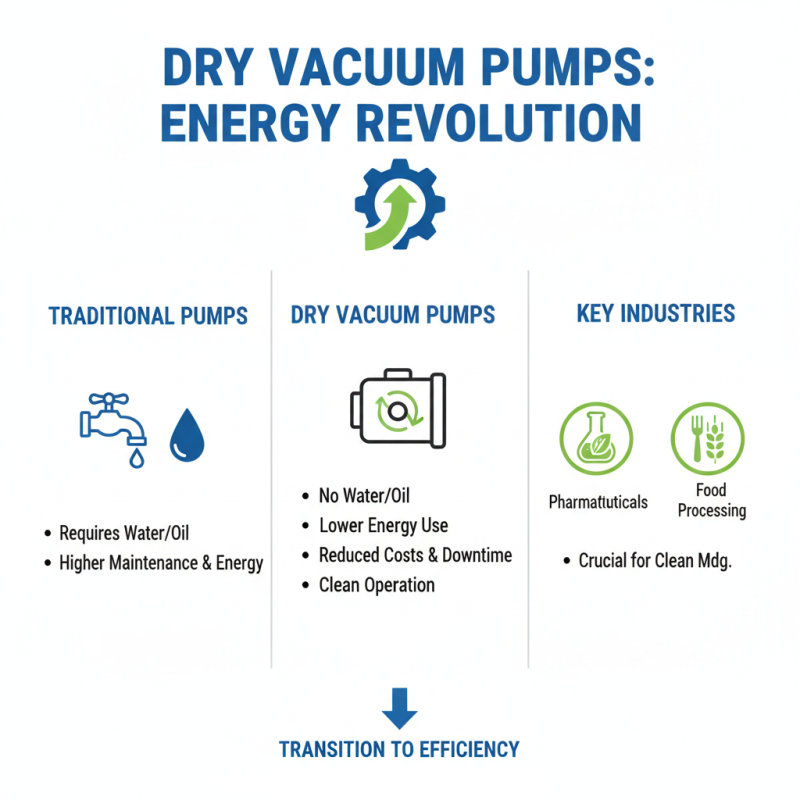

Impact of Dry Vacuum Pumps on Energy Consumption in Manufacturing

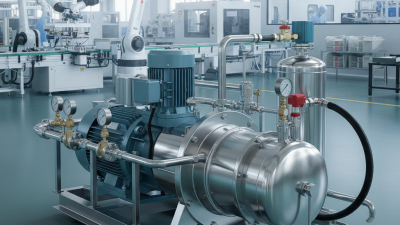

The energy consumption of manufacturing processes is a crucial element in today's industrial landscape. Dry vacuum pumps play a significant role in reducing this energy usage. These pumps eliminate the need for water or oil, leading to lower maintenance costs and increased efficiency. This transition can be pivotal in industries like pharmaceuticals and food processing, where clean environments are essential.

Despite the advantages, there are challenges. Some facilities may rely on outdated technologies. Upgrading to modern dry vacuum systems can be costly. However, the long-term energy savings can justify this investment. Companies need to assess their operations carefully. Understanding current consumption patterns helps identify where dry vacuum pumps can make a difference.

Moreover, excessive energy use can lead to higher operating costs. By implementing these efficient systems, manufacturers can reduce their carbon footprint. This ecological benefit is compelling. Nonetheless, transitioning requires planning and training, as staff may need to adapt to new technologies. It's a journey that needs commitment and reflection. Evaluating energy needs now can lead to a more sustainable manufacturing future.

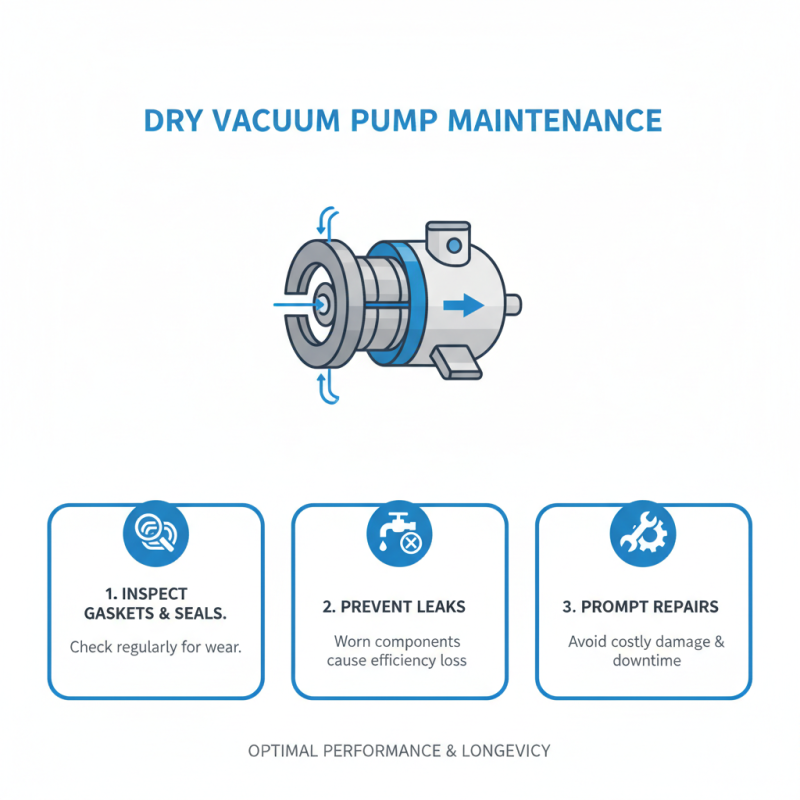

Maintenance Best Practices for Optimal Operation of Dry Vacuum Pumps

Dry vacuum pumps play a vital role in many industrial applications, requiring diligent maintenance for optimal performance. Regular inspection of gaskets and seals is essential. These components can wear out over time, leading to leaks. Addressing issues promptly can prevent further damage. Neglecting this aspect can result in decreased efficiency.

Maintaining appropriate oil levels is crucial. Low oil can lead to increased wear on internal parts. It also reduces the pump's ability to create a vacuum. Checking the oil condition regularly can help avoid these pitfalls. Users should not overlook cleaning filters and exhaust ports. Clogged filters can lead to system inefficiencies.

Monitoring performance metrics is another best practice. Keeping an eye on pressure and flow rates provides insights into the pump’s health. If readings fluctuate, it may signal an issue needing attention. Documenting maintenance activities helps track performance over time. This can guide necessary adjustments or repairs. The reality is that neglecting these steps can lead to costly downtime. It’s easy to overlook routine tasks, but consistent focus can enhance longevity.

Related Posts

-

Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

-

Top Factors to Consider When Choosing a High Vacuum Pump for Your Needs

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?