Top 5 Benefits of Using an Oil Vacuum Pump for Industrial Applications

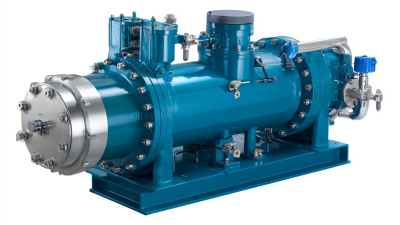

In the realm of industrial applications, efficiency and reliability are paramount. One crucial tool that has garnered significant attention is the oil vacuum pump. This innovative device serves not only to enhance operational efficiency but also to ensure the safe handling of various materials during industrial processes. The oil vacuum pump operates by creating a vacuum that effectively removes unwanted air and gases, significantly reducing the risk of contamination and increasing the integrity of the products being processed.

As industries strive to optimize their operations and reduce downtime, the benefits of using an oil vacuum pump become increasingly evident. From enhancing production efficiency to minimizing the risk of equipment failure, this technology offers multiple advantages that can lead to substantial cost savings and improved performance. Furthermore, the oil vacuum pump plays a vital role in maintaining environmental standards by effectively managing emissions and waste, making it an indispensable component in modern industrial settings. In the following sections, we will delve into the top five benefits of implementing an oil vacuum pump in various industrial applications, highlighting its importance in achieving operational excellence and sustainable practices.

Benefits of Efficient Oil Removal in Industrial Settings

Efficient oil removal is crucial in industrial settings, where machinery can accumulate oil and other contaminants, leading to decreased performance and potential equipment failures. An oil vacuum pump provides a reliable solution for effective oil extraction, thereby enhancing operational efficiency. According to a report by the International Journal of Industrial Systems, devices that utilize advanced oil removal techniques can increase equipment lifespan by up to 30%, significantly reducing maintenance costs and downtime.

In addition to prolonging machinery life, efficient oil removal helps maintain a safer working environment. Excess oil can create hazardous conditions, including slips and equipment malfunctions. Industrial hygiene standards indicate that maintaining clean work surfaces can reduce workplace accidents by 25%. Utilizing an oil vacuum pump not only aids in adhering to safety regulations but also promotes a cleaner and more organized workspace.

**Tip:** Regularly schedule oil removal sessions to prevent buildup and ensure that machinery operates smoothly. Additionally, ensure that your team is trained in proper pump operation and maintenance to maximize the efficiency of the oil vacuum system. By focusing on timely oil removal and system care, industries can achieve substantial productivity gains while fostering a safer environment for all employees.

Enhanced Equipment Longevity Through Oil Vacuum Pumps

Oil vacuum pumps play a crucial role in enhancing the longevity of industrial equipment. By effectively removing impurities and moisture from oil systems, these pumps contribute to cleaner operation, thus reducing wear and tear on machinery. When contaminants are kept at bay, the internal components of equipment can function more efficiently, leading to a longer lifespan and reduced maintenance costs. This proactive approach to equipment care not only saves time and resources but also ensures that productivity remains high.

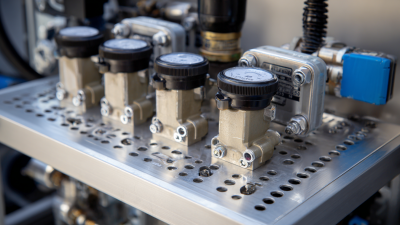

Tips for maintaining your oil vacuum pump include regularly checking for leaks and ensuring that all seals and gaskets are in good condition. This simple step can prevent contamination from entering your system, maximizing the pump's efficiency. Another suggestion is to perform routine maintenance as outlined in the user manual. Regular oil changes and inspections can significantly impact the performance of your equipment and help avoid costly downtime.

Moreover, operators should be aware of the importance of proper installation and operation practices. Ensuring that the oil vacuum pump is correctly sized for the application is essential for optimal performance. Under or over-specifying the pump can lead to operational inefficiencies, thus negating the longevity benefits. By following these best practices, businesses can fully leverage the advantages of oil vacuum pumps, leading to sustained efficiency and profitability.

Improved Operational Safety with Oil Vacuum Technology

The integration of oil vacuum technology in industrial applications significantly enhances operational safety, addressing crucial concerns in hazardous environments. A report by the National Institute for Occupational Safety and Health (NIOSH) highlighted that nearly 2.8 million nonfatal workplace injuries were reported in the United States in 2019 alone, with a significant portion arising from equipment-related accidents. Utilizing oil vacuum pumps minimizes risks associated with traditional pumping methods, as these systems operate under vacuum conditions that limit the release of harmful aerosols and vapors, thereby creating a safer work environment.

Moreover, oil vacuum pumps significantly reduce the likelihood of spills and leaks, an aspect pivotal for facilities handling toxic or flammable substances. The Environmental Protection Agency (EPA) reports that incidents of chemical spills in industrial settings can lead to severe repercussions, including costly cleanup processes and potential litigation. By employing oil vacuum technology, businesses can achieve consistent containment of fluids, thus reducing the risk of accidents and associated costs. The proactive management of safety hazards not only protects workers but also safeguards the environment, aligning with regulatory compliance and corporate responsibility standards.

Top 5 Benefits of Using an Oil Vacuum Pump for Industrial Applications

This chart illustrates the key benefits of using an oil vacuum pump in industrial settings, showcasing improved operational safety, efficiency, maintenance reduction, energy savings, and environmental impact.

Cost-Effectiveness of Oil Vacuum Pumps in Industrial Use

In industrial settings, cost-effectiveness is a critical consideration when selecting equipment, and oil vacuum pumps offer significant financial advantages. These pumps efficiently remove air and moisture from systems, which not only prolongs the lifespan of machinery but also prevents costly downtimes. By maintaining optimal operating conditions, businesses can reduce maintenance costs and improve overall productivity. The initial investment in an oil vacuum pump can be quickly recouped through savings on energy and repair expenses.

Moreover, oil vacuum pumps facilitate more efficient processes, which contributes to their cost-effectiveness in the long run. They are designed to operate efficiently over extended periods, reducing energy consumption compared to traditional pumps. Additionally, their reliability minimizes the risk of unexpected failures, leading to less frequent replacements and repairs. As industries strive to enhance profitability, the reduction in operational costs associated with oil vacuum pumps makes them an attractive option for businesses aiming to optimize their budget while maintaining high performance.

Minimizing Environmental Impact with Oil Vacuum Solutions

The use of oil vacuum pumps in industrial applications offers significant advantages, particularly in reducing environmental impact. These pumps are designed to efficiently extract oil and other contaminants from systems, which minimizes the risk of leaks and spills. By implementing oil vacuum solutions, industries can significantly lower the chances of hazardous materials entering the environment, thereby contributing to a cleaner and safer ecosystem.

Moreover, the adoption of oil vacuum pumps promotes sustainable practices within industrial settings. By ensuring proper oil management, businesses not only comply with environmental regulations but also enhance their operational efficiency. The ability to recycle and reuse oils reduces waste and cuts down on the need for new resource extraction. This not only decreases the carbon footprint associated with oil production but also fosters a culture of sustainability that benefits both the company and the community it operates within. Through such proactive measures, industries can lead the way toward more environmentally responsible operations.

Top 5 Benefits of Using an Oil Vacuum Pump for Industrial Applications - Minimizing Environmental Impact with Oil Vacuum Solutions

| Benefit | Description | Environmental Impact | Industry Application |

|---|---|---|---|

| Efficient Oil Recovery | Restores and reuses oil, reducing waste. | Lowers oil disposal impact. | Manufacturing, Automotive |

| Cost Savings | Reduces overall operational costs by minimizing oil purchases and disposal fees. | Decreases environmental costs associated with new oil production. | Food Processing, Aerospace |

| Improved Product Quality | Ensures contaminant-free oil for better product performance. | Reduces risk of pollutants entering the environment. | Pharmaceutical, Chemical |

| Reduced Emissions | Minimizes VOC emissions through effective oil handling. | Contributes to cleaner air quality. | Heavy Industry, Utilities |

| Enhanced System Performance | Maintains vacuum levels for optimal machine efficiency. | Decreases energy usage in production processes. | Textile, Electronics |

Related Posts

-

Top Benefits of Regenerative Blowers: Applications and Efficiency Explained

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

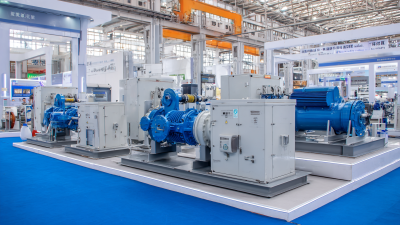

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

Why Choose a Blower Pump for Your Next Project and How It Benefits You

-

How to Choose the Right Suction Pump for Your Specific Needs

-

The Hidden Benefits of Rotary Pumps: Why They Are Essential for Modern Industries