Top Benefits of Using a Dry Vacuum Pump for Your Industrial Applications

In the rapidly evolving landscape of industrial applications, the importance of efficiency and reliability cannot be overstated. As industries increasingly seek innovative solutions to enhance their operational capabilities, the role of advanced equipment such as the dry vacuum pump becomes paramount. John Smith, a respected expert in vacuum technology, emphasizes this point, stating, "The dry vacuum pump is pivotal in optimizing processes, ensuring both cleanliness and efficiency in operations." This highlights the critical position that dry vacuum pumps hold in various industrial setups.

The benefits of utilizing a dry vacuum pump extend across multiple facets, from energy savings to improved environmental performance. These pumps are engineered to operate without the need for lubrication, which not only reduces the risk of contamination but also minimizes maintenance requirements. As industries focus on sustainability and cost-effectiveness, the dry vacuum pump stands out as a versatile solution that aligns with these goals, ensuring that facilities can maintain high standards while optimizing their resources.

Ultimately, the adoption of dry vacuum pumps in industrial applications is not just a trend, but a strategic approach to enhancing productivity and reliability. By integrating this technology, businesses can achieve significant improvements in their operations, paving the way for a more efficient and sustainable future.

Overview of Dry Vacuum Pumps in Industrial Settings

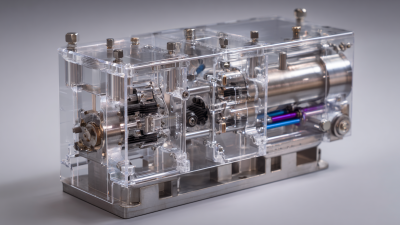

Dry vacuum pumps are essential tools in various industrial settings, providing a reliable solution for creating and maintaining vacuum conditions. Unlike traditional oil-sealed pumps, dry vacuum pumps operate without any liquid, making them ideal for applications where contamination is a concern. These pumps efficiently remove gases and vapors from systems, which is particularly important in industries such as pharmaceuticals, food processing, and semiconductor manufacturing, where product purity and operational efficiency are paramount.

In industrial applications, the choice of a dry vacuum pump can significantly impact performance and maintenance costs. The technology behind these pumps often leads to lower energy consumption and reduced operational costs compared to liquid-sealed alternatives. Furthermore, dry vacuum pumps tend to require less maintenance due to the absence of oil, leading to fewer downtimes and increased productivity. When selecting a dry vacuum pump, it's crucial to consider factors such as the required vacuum level, pumping speed, and the nature of the gases being handled.

**Tips:** When operating a dry vacuum pump, ensure that all connections are airtight to avoid any leaks that could affect performance. Regularly monitor the pump's operation parameters to maintain optimal efficiency, as this can prevent unnecessary wear and tear. Additionally, conducting routine checks on filters and other components can enhance the longevity of the pump and ensure consistent performance in industrial applications.

Key Advantages of Using Dry Vacuum Pumps

Dry vacuum pumps have become an essential tool in various industrial applications due to their unique advantages over traditional wet vacuum systems. One of the key benefits is their ability to create a clean and safe working environment. Unlike wet vacuum pumps, dry vacuum pumps do not utilize fluids for operation, which minimizes the risk of contamination in sensitive processes. This feature makes them particularly suitable for industries such as pharmaceuticals, food processing, and electronics, where maintaining purity and avoiding chemical reactions is critical.

Another significant advantage is their energy efficiency and lower operational costs. Dry vacuum pumps require less maintenance compared to their wet counterparts since they do not involve any oil or lubricants. This leads to reduced downtime and lower expenses for spare parts and service. Furthermore, many dry vacuum pumps are designed to operate continuously without overheating, which can enhance productivity in high-demand settings.

Tip: When selecting a dry vacuum pump, consider the specific needs of your application, such as the required vacuum level and flow rate.

Additionally, dry vacuum pumps contribute to sustainability efforts by minimizing waste produced during operation. Their eco-friendly design aligns with the growing industrial focus on reducing environmental impact. Businesses looking to enhance their green credentials can benefit significantly from integrating dry vacuum technologies into their processes.

Tip: Regularly inspect and maintain your dry vacuum pumps to ensure optimal performance and longevity, which is essential in maximizing your investment.

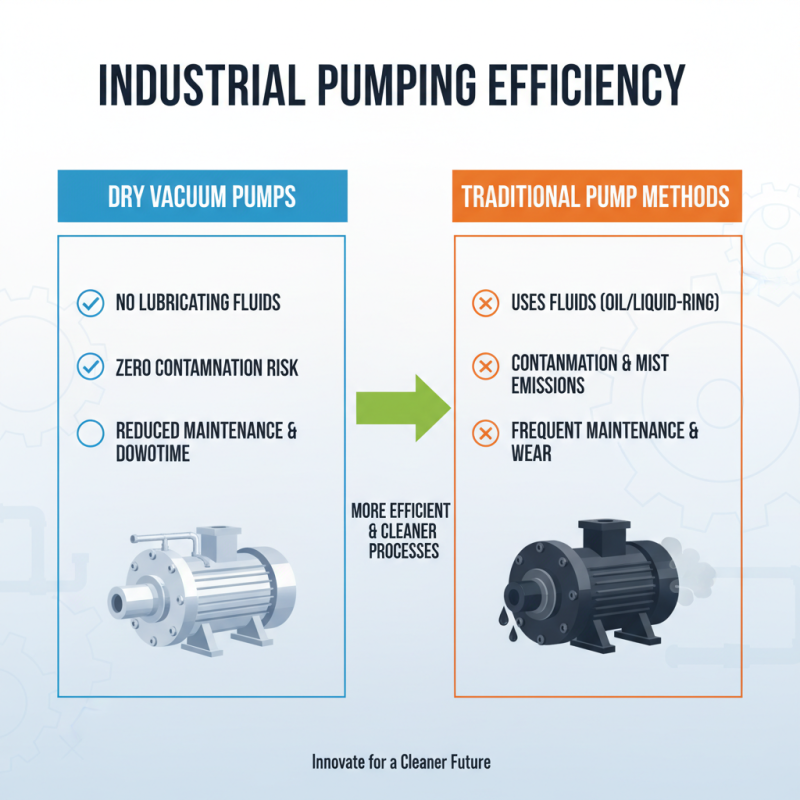

Comparison with Traditional Pumping Systems

When evaluating the efficiency of pumping systems in industrial applications, dry vacuum pumps present a compelling alternative to traditional pumping methods. Unlike liquid-ring or oil-sealed pumps, dry vacuum pumps operate without the use of lubricating fluids, which eliminates the risks of contamination in the pumped environment. This not only ensures cleaner processes but also reduces the need for regular maintenance associated with fluid management. Traditional pumping systems often face challenges such as oil mist emissions and frequent component wear due to fluid interaction, leading to higher operational costs and downtime.

Additionally, dry vacuum pumps are known for their energy efficiency. They typically consume less power than their traditional counterparts, resulting in lower energy bills and a reduced carbon footprint. This efficiency is particularly crucial in large-scale industrial operations where energy costs can significantly impact profitability. Furthermore, the compact design of dry vacuum pumps allows for easier integration into existing systems, making them a practical choice for businesses looking to upgrade their equipment without extensive modifications to infrastructure. Overall, the advantages of using dry vacuum pumps position them as a superior solution for modern industrial applications compared to traditional pumping systems.

Applications of Dry Vacuum Pumps Across Industries

Dry vacuum pumps are essential tools utilized across various industries due to their efficiency and versatility. In the pharmaceutical industry, dry vacuum pumps play a critical role in processes like freeze-drying and solvent recovery. By creating a vacuum that removes moisture without the use of oil, these pumps help maintain the integrity of sensitive compounds while enhancing product yield. Additionally, in the semiconductor manufacturing sector, dry vacuum pumps ensure a contamination-free environment essential for the delicate processes involved in chip production.

Moreover, dry vacuum pumps are employed in food processing, particularly in vacuum packaging and processes requiring precise moisture control. This helps prolong shelf life and maintain product quality by preventing oxidation and spoilage. In the chemical industry, they are vital for distillation, evaporation, and reaction processes, where a strong vacuum is required to control temperatures and increase efficiency. Their ability to handle aggressive vapors and gases without contaminating the products makes them highly desirable in sectors demanding stringent cleanliness standards.

Maintenance and Operational Considerations for Dry Vacuum Pumps

When it comes to maintaining and operating dry vacuum pumps, several key considerations can significantly affect their efficiency and longevity.

Regular maintenance is crucial, as these pumps often operate under demanding industrial conditions. This includes routine inspections to check for wear and tear on components, ensuring all seals and fittings are intact, and monitoring performance parameters such as vacuum levels and airflow.

Setting up a maintenance schedule and adhering to it can prevent unexpected downtimes and enhance the operational lifespan of the equipment.

Additionally, understanding the operational environment is essential. Dry vacuum pumps perform best under specific temperature and humidity ranges, which should be carefully monitored. Proper ventilation is also critical to prevent overheating; thus, ensuring the pump operates in a well-ventilated area or integrating cooling solutions can improve performance.

Moreover, training staff on the best operating practices and troubleshooting common issues can contribute to minimizing operational disruptions. By prioritizing these maintenance and operational considerations, businesses can maximize the effectiveness of their dry vacuum pumps and ensure they are always ready for industrial applications.

Related Posts

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know

-

Why Are Compressor Vacuum Pumps Essential for Efficient Industrial Operations?

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

The Ultimate Guide to Choosing the Right Blower and Vacuum for Your Home Cleanup Needs

-

Unlocking Efficiency: The Science Behind Dry Rotary Vane Vacuum Pumps and Their Industry Applications