Top Benefits of Regenerative Blowers: Applications and Efficiency Explained

Regenerative blowers have emerged as essential components in various industrial and commercial applications, offering significant benefits in terms of efficiency and performance. These devices utilize a unique operational principle that enables them to generate a consistent airflow while consuming less energy compared to other blower types. This advantage makes regenerative blowers an appealing choice for businesses seeking to enhance their operational efficiency while reducing energy costs.

One of the standout features of regenerative blowers is their versatility, as they can be employed in a multitude of applications ranging from wastewater treatment to packaging and material handling. Their ability to deliver high-volume airflows at varying pressures opens up a wealth of possibilities across numerous industries. Additionally, the compact design of regenerative blowers facilitates easy integration into existing systems, providing a seamless solution that doesn't compromise space or performance.

In this article, we will delve into the top benefits of regenerative blowers, exploring their applications and the efficiency they offer. By understanding the advantages these blowers bring to various sectors, businesses can make informed decisions that not only improve their bottom line but also contribute to sustainable practices in their operations.

Understanding Regenerative Blowers: A Comprehensive Overview

Regenerative blowers, known for their unique design and operational efficiency, are increasingly utilized across various industries. These blowers leverage a simple yet effective mechanism to generate high airflow with minimal energy consumption. They operate by drawing in air and utilizing a series of precision-engineered impellers to increase its pressure. This process, based on the regenerative principle, allows for significant airflow rates while maintaining quiet operation and low maintenance needs, making them ideal for applications requiring continuous or consistent air supply.

In addition to their efficiency, regenerative blowers are versatile tools that find applications in different sectors. They are widely used in wastewater treatment plants, where they facilitate aeration processes crucial for microbial digestion. Furthermore, their capacity to create vacuum and pressure is beneficial in material conveying systems, packaging industries, and pneumatic conveying, where materials must be moved or processed efficiently. Their compact design and reliability make regenerative blowers a preferred choice for businesses looking to optimize their operations while minimizing energy use and maintenance costs.

Top Benefits of Regenerative Blowers: Applications and Efficiency

This chart illustrates the efficiency and applications of regenerative blowers in various industries. The data reflects average operational efficiencies and common applications.

Key Applications of Regenerative Blowers in Various Industries

Regenerative blowers are renowned for their versatility and efficiency across a range of industries. These blowers excel in applications such as wastewater treatment, where they provide aeration to support biological processes by delivering the necessary oxygen. In the packaging industry, regenerative blowers create a gentle yet powerful air flow, ensuring that products remain secure during transport and packaging. They are also widely used in pneumatic conveying systems, enabling the movement of bulk materials efficiently over long distances.

When considering the use of regenerative blowers, there are a few tips to enhance their performance. First, ensuring regular maintenance is crucial for sustained efficiency; this includes checking for any blockages and cleaning filters periodically. Second, selecting the right size for your application can maximize performance—oversized blowers may lead to wasted energy, while undersized units can cause inadequate airflow. Finally, understanding the specific requirements of your application will guide you in adjusting the blower's settings for optimal results.

In addition to these applications, regenerative blowers are also common in the food and beverage industry, where they help in processes like sorting and cooling. They facilitate efficient air handling in commercial HVAC systems, enhancing indoor air quality while maintaining energy efficiency. The adaptability of regenerative blowers to meet diverse operational needs underscores their significance in modern industry.

Exploring the Efficiency of Regenerative Blowers: How They Work

Regenerative blowers, also known as side channel blowers, utilize a unique mechanism to create airflow efficiently. These devices operate on the principle of kinetic energy transfer, where the rotating impeller within the blower increases the air's velocity and subsequently converts it into pressure. According to a report by the International Journal of Engineering Research and Applications, regenerative blowers typically achieve efficiencies in the range of 60-80%, making them an optimal choice for various industrial applications. Their design allows for continuous operation and minimal maintenance, significantly reducing operational costs over time.

The versatility of regenerative blowers extends to multiple sectors, including wastewater treatment, pneumatic conveying, and material handling. For instance, in the wastewater treatment industry, these blowers are integral to aeration processes, where oxygen is supplied to bacteria for breaking down organic materials. Data from the American Society of Mechanical Engineers indicates that using regenerative blowers instead of traditional rotary vane blowers can result in energy savings of up to 30%, demonstrating their efficiency not only in airflow generation but also in energy consumption. By understanding the operational principles and benefits of regenerative blowers, industries can enhance their processes while minimizing environmental impacts.

Top Benefits of Regenerative Blowers: Applications and Efficiency Explained

| Benefit | Description | Common Applications | Efficiency Rating |

|---|---|---|---|

| High Efficiency | Regenerative blowers provide high airflow with lower energy consumption. | Aquaculture, Pneumatic Conveying | Up to 70% energy efficiency |

| Compact Design | Their small footprint makes them ideal for space-limited installations. | Food Processing, Packaging | Limited space utilization |

| Low Maintenance | They require minimal maintenance due to fewer moving parts. | Wastewater Treatment, HVAC Systems | Reduced maintenance costs |

| Versatile Operation | Can handle a wide range of applications across different industries. | Textile, Chemical Processing | Wide operational range |

| Noise Reduction | Designed to operate quietly, reducing noise pollution in facilities. | Medical Laboratories, Cleanrooms | Noise level ≤ 65 dB |

Advantages of Using Regenerative Blowers Over Other Blower Types

Regenerative blowers have gained significant traction in various industrial applications due to their unique efficiency and effectiveness compared to other blower types. One of the primary advantages of regenerative blowers is their ability to provide a continuous and stable airflow while maintaining a relatively low operational cost. Unlike positive displacement blowers that can be less efficient and require more maintenance, regenerative blowers utilize a simple design, which contributes to their reliability and longevity. This makes them an excellent choice for operations that demand consistency, such as in pneumatic conveying and vacuum suction applications.

Additionally, regenerative blowers are known for their energy efficiency. They operate on the principle of moving air through a series of impellers, allowing for high-volume air movement without excessive energy consumption. This is particularly beneficial in industries where energy costs are a significant concern. Furthermore, regenerative blowers produce lower noise levels compared to many other blower types, making them more suitable for environments where noise reduction is important. Their compact design also saves valuable space in facilities, allowing for more flexible installation options.

These advantages collectively make regenerative blowers a preferred option for many applications across different industries.

Maintenance Tips for Enhancing the Lifespan of Regenerative Blowers

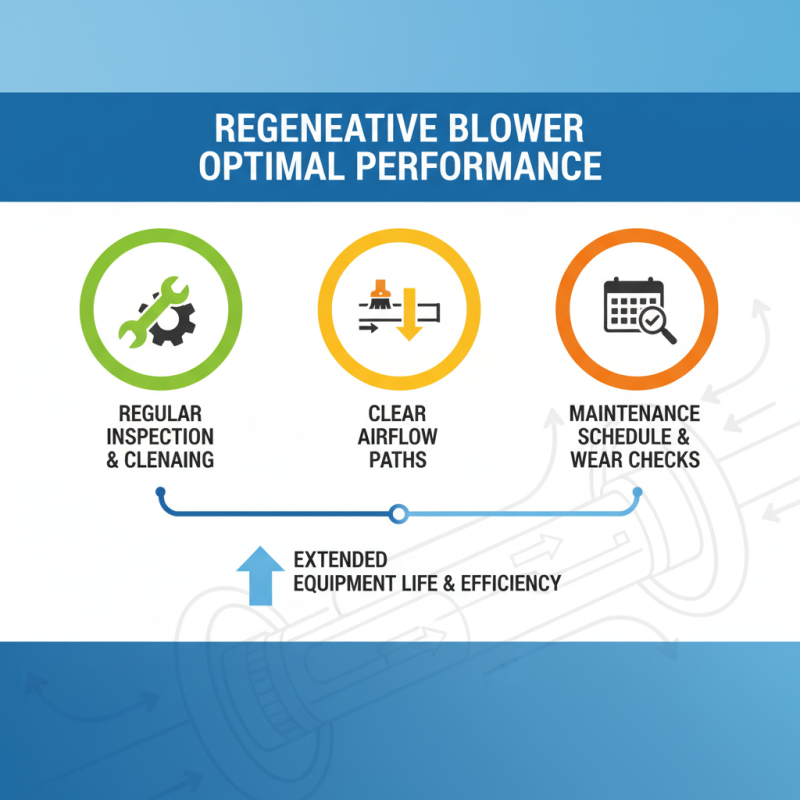

Proper maintenance is crucial for enhancing the lifespan and performance of regenerative blowers. Regular inspection and cleaning of key components, such as filters and vents, can prevent the buildup of debris that may hinder airflow efficiency. Keeping the blower's intake and exhaust pathways clear not only promotes optimal operation but also reduces strain on the motor, leading to lower energy consumption and extended equipment life. It's advisable to establish a maintenance schedule that includes checks for wear on bearings and seals, ensuring that any potential issues are addressed promptly.

Another essential maintenance tip is to monitor operating conditions, including temperature and pressure levels. Maintaining recommended operating parameters helps to avoid excessive heat and strain that could lead to premature failure. Additionally, lubricating moving parts according to manufacturer guidelines helps minimize friction and wear. Tracking operational hours can assist in determining when more intensive service, such as replacing worn parts, is necessary. By following these maintenance tips, operators can ensure their regenerative blowers operate efficiently and last longer, ultimately supporting enhanced productivity in various applications.

Related Posts

-

Top 10 Blower and Vacuum Models of 2023: Efficiency, Power, and User Ratings Reviewed

-

Understanding Regenerative Blowers: Types, Applications, and Benefits

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

Exploring the Efficiency of Rotary Pumps: A Comprehensive Guide for Industrial Applications

-

Top 10 Vacuum Pump Oils: Choosing the Best for Optimal Performance

-

10 Effective Tips for Choosing the Right AC Pump for Your Needs