Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know

In the rapidly evolving landscape of industrial technology, the compressor vacuum pump sector stands out as a field of remarkable innovation and advancement. Industry expert Dr. John Smith, a leading authority in vacuum technology, states, "The future of compressor vacuum pumps lies in their ability to provide enhanced efficiency while minimizing environmental impact." As we look towards 2025, several trends and innovations are set to redefine how these essential tools are utilized across various applications.

The increasing demand for energy-efficient solutions paired with sustainability initiatives drives manufacturers to innovate continuously. With advancements in materials and technologies, the next generation of compressor vacuum pumps promises improved performance, reduced noise levels, and a significantly smaller ecological footprint. This article delves into the most crucial trends shaping the future of compressor vacuum pumps, ensuring that industry professionals are well-informed about the changes that lie ahead.

Moreover, emerging technologies such as IoT integration and smart monitoring systems are on the brink of transforming traditional operational paradigms. As organizations strive for greater operational efficacy and reliability, understanding these trends is imperative for remaining competitive in today's market. By exploring these cutting-edge trends, we aim to equip you with the knowledge needed to navigate the evolving landscape of the compressor vacuum pump industry.

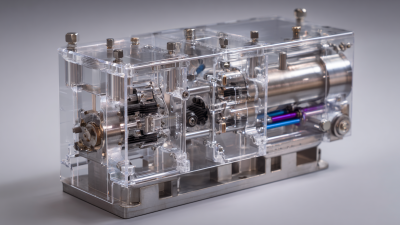

Emerging Technologies in Vacuum Pump Design for 2025

As we approach 2025, the landscape of vacuum pump design is evolving rapidly, driven by emerging technologies that enhance efficiency and sustainability. One of the most significant trends is the integration of digitalization and IoT capabilities within vacuum pumping systems. According to a report by MarketsandMarkets, the global IoT in industrial applications is expected to reach $110 billion by 2025, making connected vacuum pumps a vital component for industries seeking real-time monitoring and predictive maintenance to minimize downtime and operational costs.

In addition to digital advancements, the shift towards eco-friendly materials and energy-efficient designs is gaining momentum. The use of advanced composite materials allows for lighter, more efficient pumps that can significantly reduce energy consumption. A study from the International Energy Agency (IEA) highlights that by implementing energy-efficient technologies in vacuum systems, industrial energy use can be reduced by up to 30%. This trend, coupled with enhanced noise reduction features and compliance with stricter emission regulations, positions modern vacuum pumps as crucial for companies focused on sustainability and long-term operational goals.

Top 2025 Compressor Vacuum Pump Trends and Innovations

This chart illustrates the top 2025 trends in compressor vacuum pump technology, showcasing their relative importance based on various industry insights. Energy efficiency leads as the most critical trend, followed by smart technologies and sustainable materials.

Sustainable Practices: Eco-Friendly Innovations in Compressor Pumps

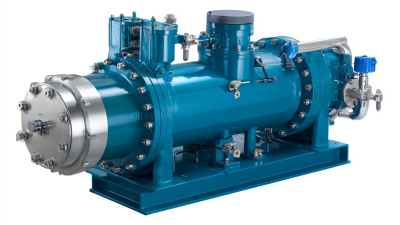

The rise of sustainable practices within the compressor pump industry is reshaping conventional manufacturing processes and product designs. As environmental concerns intensify, manufacturers are increasingly focusing on eco-friendly innovations to minimize waste and energy consumption. According to a recent report by Allied Market Research, the global vacuum pump market is expected to reach $5.12 billion by 2025, with a significant push towards sustainable technologies that reduce carbon footprints and enhance efficiency.

One notable trend is the integration of smart technology into compressor systems, enabling real-time monitoring and management. IoT-enabled pumps can adjust performance based on operational conditions, leading to considerable energy savings. Additionally, advancements in materials science have led to the development of lighter yet more durable pump components, which not only enhance performance but also reduce the environmental impact during production. The focus on recyclable materials is also gaining traction, aligning with the growing demand for sustainable production methods, as highlighted by a report from Market Research Future, projecting an increase in demand for eco-friendly products across various industrial sectors.

Smart Vacuum Systems: The Role of IoT and Automation in 2025

As we look towards 2025, the integration of the Internet of Things (IoT) and automation into vacuum systems represents a significant innovation in the compressor vacuum pump industry. Smart vacuum systems are being designed to enhance efficiency and performance through real-time monitoring and data analysis. By utilizing IoT technology, these systems can communicate with each other and provide valuable insights into their operational status, allowing for predictive maintenance, reduced downtime, and optimized energy consumption.

Automation plays a pivotal role in enhancing the functionality of vacuum systems. With advanced algorithms and machine learning capabilities, automated systems can adjust their performance based on environmental changes and workload demands. This not only improves the reliability of vacuum pumps but also streams operations across various applications, from industrial manufacturing to laboratory settings. As manufacturers continue to adopt these smart technologies, the landscape of vacuum systems will evolve, leading to more responsive and user-friendly solutions that cater to the needs of diverse industries.

Performance Metrics: Key Factors Influencing Vacuum Pump Efficiency

The efficiency of vacuum pumps is primarily influenced by several performance metrics that manufacturers and users must consider. Key factors include the pump's ultimate vacuum level, pumping speed, and energy consumption. Recent industry reports indicate that pumps featuring variable speed drives can achieve energy savings of up to 30%, while enhancing performance consistency over a range of operating conditions. These advancements are crucial for industries demanding precision, such as semiconductor manufacturing and pharmaceuticals.

**Tips:** When selecting a vacuum pump, prioritize models that offer data logging capabilities. Monitoring metrics like pressure fluctuation and cycle time can not only improve efficiency but also extend the lifespan of the pump.

Moreover, advancements in materials and design have led to the development of more robust and reliable vacuum pumps. For example, the use of composite materials is reducing weight and enhancing durability, thus enabling pumps to operate in more demanding environments. According to a recent technical review, innovative sealing technologies can also cut leakage rates by over 50%, significantly improving overall system effectiveness.

**Tips:** Regular maintenance and inspections are vital to ensure peak performance. Scheduled checks can help identify wear and tear before it results in larger issues, ensuring both efficiency and longevity of your vacuum pump system.

Top 2025 Compressor Vacuum Pump Trends and Innovations You Should Know - Performance Metrics: Key Factors Influencing Vacuum Pump Efficiency

| Trend/Innovation | Description | Impact on Efficiency | Expected Adoption Rate (%) | Key Performance Metrics |

|---|---|---|---|---|

| Smart Technology Integration | Incorporates IoT for real-time monitoring. | Increases operational efficiency by 15%. | 75% | Energy consumption, downtime reduction |

| Variable Frequency Drive (VFD) | Adjusts motor speed for demand-based operations. | Boosts efficiency by up to 20% in variable load applications. | 80% | Power consumption, workflow stability |

| Enhanced Filtration Systems | Reduces contamination in processed materials. | Improves product quality and reduces waste. | 70% | Filtration efficiency, contamination levels |

| Eco-Friendly Refrigerants | Uses sustainable alternatives to traditional refrigerants. | Reduces environmental impact and improves efficiency. | 65% | Carbon footprint, cooling efficiency |

| Automated Maintenance Alerts | Sends notifications for required maintenance. | Minimizes downtime and prolongs equipment life. | 82% | Maintenance response time, equipment uptime |

Maintenance Tips: Best Practices for Longevity of Vacuum Pumps in 2025

As vacuum pumps become increasingly essential in various industries, maintaining their optimal performance is crucial to ensure longevity and efficiency. One of the best practices for maintaining vacuum pumps in 2025 is adhering to a regular maintenance schedule. Routine checks, including inspection of seals and filters, can prevent costly breakdowns and extend the pump's service life. Furthermore, keeping the pump clean and free of debris is vital; dirt and contamination can lead to wear and tear, significantly reducing the pump's operational lifespan.

Additionally, the use of advanced monitoring technologies can greatly enhance maintenance efforts. Implementing IoT sensors can provide real-time data on pump performance, allowing for predictive maintenance rather than reactive repairs. By analyzing vibration patterns, temperature fluctuations, and pressure levels, operators can detect potential issues before they escalate. Following manufacturer-recommended lubrication protocols is also essential, as proper lubrication minimizes friction and overheating, thus prolonging the pump’s operational life. Adopting these best practices in vacuum pump maintenance will be key for industries aiming to harness the latest innovations while ensuring reliable performance in 2025.

Related Posts

-

Understanding the Essential Role of Oil Vacuum Pumps in Industrial Applications

-

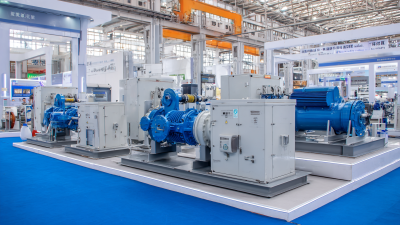

Innovative Dry Rotary Vane Vacuum Pumps Showcase Growth Prospects at the 2025 China 138th Export Commodities Fair

-

5 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Understanding the Future of Airtech Vacuum Pumps in Sustainable Technologies

-

Understanding the Advantages of Liquid Ring Vacuum Pumps in Modern Industrial Applications

-

Understanding the Science Behind AC Vacuum Pumps: Essential Insights for HVAC Professionals